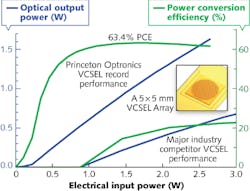

Years of research and development, including funding from the U.S. Navy, Army, and the Defense Advanced Research Products Agency (DARPA), have resulted in record performance of vertical-cavity surface-emitting lasers (VCSELs) from Princeton Optronics (Mercerville, NJ). The VCSELs (both single-emitter and array devices) have 63.4% power conversion efficiency (PCE)—an unprecedented value, considering that commercially available products have typical PCE values of around 20 to 25%.

Developed for time-of-flight (TOF) and structured-light applications for gesture recognition, three-dimensional imaging, and infrared illumination applications, the 800–1100 nm VCSEL arrays are available with dimensions ranging from 500 × 500 μm to 5 × 5 mm, with power output ranging from 500 mW to several hundred watts. The VCSEL devices also have high efficiency at high temperature and power levels: typically 55% PCE at 50ºC. The VCSEL arrays are therefore easily combined to deliver up to 100 kW of continuous-wave output for high-power illumination applications in perimeter and border security, imaging through smoke and explosions, and long-range surveillance. Contact Chuni Ghosh at [email protected].

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.