Fiber Lasers: 3C optical fibers improve large-mode-area MOPA designs

High-precision laser materials processing applications typically require sub-nanosecond pulses with high peak and average powers. Furthermore, those high peak powers must be applied in small focal spots with extreme consistency; consequently, near-diffraction-limited beam quality is crucial. This beam quality is not simply captured by the ubiquitous M squared (M2) parameter, but also includes quantification of beam circularity through the focal range, beam pointing over time, and power stability.

Without all of these parameters working in unison, most laser processes will struggle to achieve the desired performance. A fiber master oscillator power amplifier (MOPA) can meet the needs of such applications by coupling two critical components: temporally agile, highly stable short-pulse seed lasers and large-mode-area (LMA) optical fiber technologies.

Several state-of-the-art LMA fiber types enable high-peak-power performance by scaling mode area to increase the threshold for the onset of nonlinear effects, but often these technologies struggle to meet the most demanding beam quality parameters over long system lifetimes. Those that do meet beam quality requirements are generally complex and costly to work with due to the need for free-space optics and high-precision coupling into fibers often containing air-based microstructures.

Fortunately, chirally coupled core (3C) optical fibers can overcome these LMA limitations. Coupling nLIGHT's patented 3C fibers with a short-pulse-seed semiconductor laser platform results in a picosecond-class pulsed fiber laser MOPA with flexible pulse duration, repetition rate, and pulse burst size.

3C fiber architecture

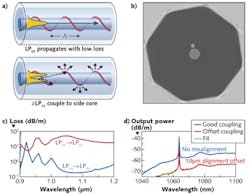

With a large central core doped with the desired gain medium and surrounded by one or several satellite cores, 3C fibers are spun during the drawing process at high rates, causing the satellite cores to orbit the main core along the fiber length with a pitch on the order of a few millimeters. The pitch of the helix period can create a quasi-phase-matching condition between the modes of the main core and those of the satellite core where strong coupling between the two occurs (assuming the two cores are in evanescent contact).

This strong-coupling condition is expressed by βmc-βsc+m⋅2π/Λ = 0, where β is the propagation constant of the main core or side core and Λ is the helix pitch.1,2 Fibers can be designed such that the fundamental mode of the main core experiences low loss from this process, while the higher-order modes (HOMs) in the main core are strongly coupled to the side core(s), where they are radiated away to the cladding. The result is a fiber that can have tens of dB/m HOM suppression, resulting in effectively pure single-mode operation (see Fig. 1).

With typical M2 < 1.15 and core circularity of 95% or better, 3C beam quality is often limited by measurement error. Life testing of 33 μm core 3C fibers for a continuous 4500 hours to date with hundreds of kilowatts of peak power shows no signs of beam quality change or substantial power degradation thanks to nLIGHT's low-photodarkening ytterbium (Yb)-doped glass.

As mentioned earlier, modally induced pointing effects are also mitigated in 3C fiber due to their high-purity fundamental mode operation. The typical highly circular output near-field profile and plots of beam position within the fiber core versus power indicate minimal dynamic modal-induced pointing in the system (see Fig. 2).Pointing was measured at a total of eight different power settings in approximately 2.4 W steps from seed only up to 19.2 W. The beam centroid was tracked for 30 s at each point by the camera software and points at 0.5 s sampling rate were recorded in the plot for the approximately 4 min. total test resulting in a maximum mode deviation of 0.5 μm in any direction, corresponding to 1.8% of the mode field diameter.

This pointing was not measured in a fully packaged system, but rather on a lab breadboard system with the fiber tip secured by tape and cantilevered off the mounting base. It is likely that much of the measured motion vs. power in the y-direction is due to thermal effects on the minimally secured fiber. The x-direction motion is of similar magnitude to the accuracy of the measurement system (around 0.1 μm measurement accuracy and about 0.3μm maximum motion), so modal-induced beam motion is effectively negligible and would be reduced further in a packaged system.

In other publications, 33 μm core 3C fibers have reportedly shown > 511 W continuous-wave (CW) output powers and multi-millijoule pulse energies for 10 ns pulses.3 In our work, we concentrate on their capacity for achieving high peak powers with modest, tens-of-watts average power and their utility in amplification of bursts of pulses.

3C MOPA performance

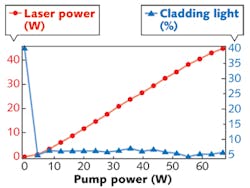

Minimal impact on laser efficiency compared to conventional fiber technology was noted when testing under a variety of single-pulse and multiple-pulse regimes for a wide range of pulse durations and pulse repetition frequencies from 50 ps to 1 ns and tens of kilohertz to megahertz, respectively, using 33 μm 3C fiber incorporated into a MOPA with the pulsed fiber laser (PFL) seed architecture (consisting of nLIGHT's single-emitter diode laser modules and low-photodarkening fibers). Power scaling to 45 W yields about 73% slope efficiency and 65% absolute optical-to-optical power conversion for a 1 ns seed laser running at 1 MHz (see Fig. 3).Inherent to the nature of 3C fiber, there is a small background loss on the LP01 mode caused by fabrication imperfections; in addition, there is slight bend-induced loss-both on the order of a few tenths of a dB/m. These losses result in cladding light being generated by the distributed losses along the fiber. In these experiments, cladding light is not included in reported powers, as it is filtered out by a hard aperture placed in a re-imaged near-field of the beam.

In the arrangement used for these experiments (30 cm fiber coiling diameter), the cladding light is approximately 6% of total power, with relatively constant value from low to high amplifier power. The one exception is that in the unpumped state, clad light is close to 40%. This stems from differential losses on the clad and core light caused by Yb absorption and also by light launched from a mismatched splice at the input of the amplifier. The constant value of cladding light content when pumped indicates that operation at high powers does not create additional HOMs via thermal effects or other perturbation, and thermal effects are not required at low powers to maintain high beam quality, unlike other types of LMA fiber technologies.

The net effect of high-gain operation and the slight bend-induced and fiber-structure-induced background losses are the cause for the lower-than-quantum-defect-limited amplifier performance. It should also be noted that beam quality remains near-diffraction limited with M2 < 1.15 and beam circularity effectively unchanged at all output power levels.

A semiconductor-based PFL seed system produces adjustable-duration, arbitrary-repetition-rate pulses on demand with high stability and minimal pulse distortion during amplification (see Fig. 4). Testing from 50 ps to 1 ns in both single-pulse- and adjustable-pulse-spacing burst modes for the 3C amplifier system enables 300 kW peak power levels to be reached before parasitic nonlinear effects begin to draw power out of the narrow band around 1064 nm.Although large-core 3C fibers allow significant energy storage with multi-millijoule energy extraction possible, short single-pulse mode peak power limits energy to several hundred microjoules; fortunately, short-pulse burst-mode operation can make full use of this stored energy. Furthermore, when a narrowband spectral filter is applied to the pulses, they do not change shape or decrease in power, indicating that all spectral power is in-band of the fundamental 1064 nm wavelength using a 4 nm bandpass filter.

The limiting nonlinear effect for properly aligned 3C fibers is stimulated Raman scattering (SRS), which is a typical phenomenon in all high-peak-power LMA-fiber-based MOPA systems in the picosecond and low-nanosecond range. Depending on the pulse duration in the 50 ps to 1 ns regime, self-phase modulation can also be a strong effect. Spectral broadening on the order of 4 nm at 15 dB width occurs at 300 kW and 50 ps, while only small broadening is observed in 1 ns class pulses.

The relatively narrow spectrum and stable polarization properties of 3C suit frequency conversion to green and ultraviolet wavelengths; in addition, we recently fabricated larger 55 μm core 3C fibers that are expected to approach the megawatt peak power regime with excellent near-diffraction-limited beam quality over time, with even further power scaling on the horizon.

REFERENCES

1. M. C. Swan et al., "33 μm core effectively single-mode chirally-coupled-core fiber laser at 1064-nm," OFC-NFOEC, San Diego, CA (2008).

2. X. Ma et al., Opt. Exp., 19, 27, 26515–26528 (2011).

3. T. Sosnowski et al., "3C Yb-doped fiber based high energy and power pulsed fiber lasers," SPIE Photonics West 2013, 8601-57, San Francisco, CA (Feb. 7, 2013).

Rob Martinsen | CTO, nLIGHT

Rob Martinsen is chief technology officer (CTO) at nLIGHT (Camas, WA).

Michael Atchley | Director of Product Marketing, nLIGHT

Michael Atchley is director of product marketing at nLIGHT (Camas, WA).

Timothy S. McComb | Fiber Laser Principal Designer, nLIGHT

Timothy S. McComb is fiber laser principal designer at nLIGHT (Camas, WA).

Joona J. Koponen | Director of Fiber Design, nLIGHT

Joona J. Koponen is director of fiber design at nLIGHT (Camas, WA).