Single-photon Counting: New silicon photomultiplier structure promises more efficient photon detection

FEI SUN and GUO-QIANG LO

Silicon photomultipliers (SiPMs) have been developed in recent years as a possible alternative to traditional photomultiplier tubes (PMTs).1-3 By harnessing mature Si process technologies used in the semiconductor industry, SiPMs have exhibited many advantages over PMTs, such as compactness, low-bias-voltage operation, insensitivity to magnetic fields, and fast response.4 Nowadays the performance of SiPMs in single-photon detection is fast approaching those of conventional PMTs. In addition, SiPMs have found widespread application in many different areas.5

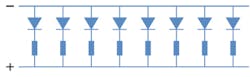

A SiPM is formed of a large array of identical cells in parallel connection, each of which consists of one avalanche photodiode (APD) and one serial quenching resistor (Fig. 1). To achieve high resistance (on the order of 105 ΩΩ) for effective quenching of avalanche current (as the devices are principally operating in Geiger mode), the resistors are normally made of lightly doped poly-Si strips, which are located on top of the APDs and are connected with them by means of metal wires. Thus, certain portions of the surface area of the device should be reserved to accommodate the metal wires, poly-Si resistors, and so on. Therefore, photons launched in these "dead regions" are unlikely to be detected, which thus affects the photosensitivity.

In this article, we will show how compactly integrated bulk-Si quenching resistors are introduced to replace poly-Si resistors in SiPM cells. In the proposed SiPM structure, no metal wires are needed for the serial connection of APD and quenching resistor because they are connected to each other inherently by placing the silicon resistors vertically beneath the sensing elements. Thus, the fill factor of the device can be greatly improved and better performance will be expected for the new device.

SiPM with vertical bulk-Si resistors

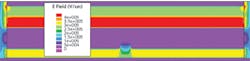

A cross-section of adjacent SiPM cells with vertical bulk-Si quenching resistors is shown in Fig. 2(a). The compactly integrated bulk-Si quenching resistor is vertically connected to the APD, where two n+ regions serve as two terminals for the quenching resistor. The connection between the APD, which is basically a diode, and the resistor is illustrated more clearly in Cell 2 by electronic symbols (see Fig. 2a). To reduce the thickness of the resistor layer, a p region was inserted between two n+ regions. The p region covers the whole device area except for small holes at the cell centers. When a bias is applied, the current passing the resistor can only flow through the small holes in the p region, because the n+-p-n+ structure serves as two back-to-back diodes and effectively blocks the current flow. Thus, a bulk-Si resistor with very small equivalent cross-section can be defined by semiconductor processing technology. Accordingly, a very thin epitaxial Si layer will be sufficient to achieve the necessary high resistance.The p+-p-n+ layers in Fig. 2(a) show that the APD is based on a separate absorption, charge, and multiplication (SACM) structure. Since the APD and the resistor structure are sharing one n+ region, they are connected inherently with no metal wires needed. Furthermore, isolation trenches are introduced between adjacent cells to reduce electrical and optical cross-talk. On top of the device surface, only small areas of metal are needed to connect the p+ regions of all SiPM cells together to form the upper electrode of the SiPM as seen in Fig. 2(b). Thus, the fill factor of the whole device is greatly improved due to the reduction of dead regions.

Numerical simulation of proposed structure

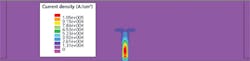

Technology computer-aided design (TCAD)-based software was used to simulate the fabrication processes and device characteristics of the proposed SiPM cell structure. For simplicity, a SiPM cell with cylindrical symmetry was adopted. The doping profile defined in the considered device is shown in Fig. 3.As can be seen, the strongest electric field is concentrated exclusively in the multiplication region of the APD, which indicates that the introduction of the vertical bulk-Si resistor layer does not change the electric-field distribution of the APD, and the functionality of SiPM can therefore be guaranteed. The current density shows the expected distribution as well. As shown in Fig. 5, the p current blocking region manages to define the direction of the avalanche current such that it can only find its way through the small resistor holes at the cell center.

Experiments and results

Based on the proposed structure, some SiPMs with vertical bulk-Si resistors have been designed and fabricated. The designed SiPM contains 100 identical square cells, each of which is 50 by 50 μm. Due to the elimination of poly-Si quenching resistors on the device surface, a fill factor as high as 81% has been obtained. In Table 1, the fill factor of our SiPM is compared with those of some commercial products, demonstrating that the fill factor of our device is higher.

The proposed SiPM structures shown in Fig. 2(a) are achieved on 8-in. Si wafers (As-doped, 1020 cm-3). The device layers are deposited on top of the n+ substrate by epitaxial growth of nonintentionally doped Si using ultrahigh-vacuum chemical vapor deposition (UHVCVD) technology. Ion implantation of boron or phosphorous dopants is inserted between Si deposition steps to realize the expected device structures.

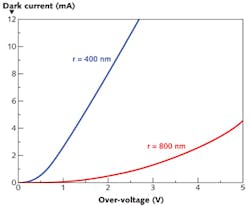

Four occurrences of Si epitaxial growth and four of ion implantation are needed to realize the proposed structure. The thicknesses of multiplication layer and absorption layer in the SiPM are 600 nm and 200 nm, respectively. The total thickness of the vertical resistor layer is designed to be 1 μm; the current blocking layer (p region) is located in the middle of the resistor layer. Resistor holes with two differing radii of 400 nm and 800 nm have been used to realize different quenching resistances.

The I-V characteristics of the fabricated devices are measured. The breakdown voltage of the device is around 23 V. The relations between the avalanche current and the overvoltage applied are shown in Fig. 6. As can be seen, although the I-V curves are not strictly linear, quite good resistor properties can still be observed. The nonlinearity can be attributed to the thickness change of the depletion region.When a different bias is applied to the resistor, the depletion region change around the p region will accordingly change the effective dimension of the resistor hole. The equivalent resistance of the vertical resistors increases with the decreasing hole dimension. For the resistor with a hole radius of 400 nm (r = 400 nm curve in Fig. 5) in the current blocking layer, its equivalent resistance is calculated to be about 100 kΩ. For the r = 800 nm case, however, its equivalent resistance is only 20 kΩ. This result shows that the proposed vertical bulk-Si resistors are quite competent replacements for the poly-Si quenching resistors in conventional SiPM devices.

References

1. D. Renker, "Geiger-mode avalanche photodiodes, history, properties and problems," Nucl. Instrum. Methods Phys. Res. A, 567, 48–51 (2006).

2. W. J. Kindt, N. H. Shahrjerdy, and H. W. van Zeijl, "A silicon avalanche photodiode for single optical photon counting in the Geiger mode," Sens. Actuators A, 60, 98–102 (1997).

3. V. D. Kovaltchouk, G. J. Lolos, Z. Papandreou, and K. Wolbaum, "Comparison of a silicon photomultiplier to a traditional vacuum photomultiplier," Nucl. Instrum. Methods Phys. Res. A, 538, 408–415 (2005).

4. Y. Musienko, "Advances in multipixel Geiger-mode avalanche photodiodes (silicon photomultipliers)," Nucl. Instrum. Methods Phys. Res. A, 598, 213–216 (2009).

5. J. Ninkovic, L. Andricek, G. Liemann, G. Lutz, H. Moser, R. Richter, and F. Schopper, "SiMPl - An avalanche diode array with bulk integrated quench resistors for single photon detection," Nucl. Instrum. Methods Phys. Res. A, 617, 407–410 (2010).

6.http://www.hamamatsu.com/resources/pdf/ssd/s12572-025_etc_kapd1043e03.pdf

7.http://www.sensl.com/downloads/ds/DS-MicroBseries.pdf

9.http://www.ketek.net/products/sipm/pm3350/

Fei Sun and Guo-Qiang Lo are scientists at A*STAR Institute of Microelectronics, 11 Science Park Road, Singapore Science Park II, Singapore 117685; email: [email protected].