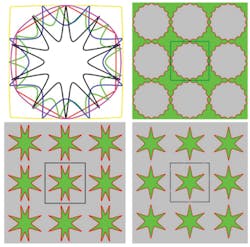

"Fishnet" 2D metamaterials, which have arrays of identical apertures that perforate a structure consisting of thin-film metal layers alternating with dielectric layers, can have a negative refractive index (NRI) at visible and near-IR wavelengths. In the interests of broadening the NRI bandwidth from previous ranges, researchers at RMIT University (Melbourne, Australia) and the University of Sydney (Sydney, Australia) have been experimenting with apertures having complex shapes, including six- and eight-point stars, derived from an evolutionary algorithm. Their theoretical study of fishnet structures with a square unit cell 300 nm in size results in detailed information about the wavelength ranges over which the metamaterials have a double negative refractive index (DNRI), where both permeability and permittivity are negative, and the NRI, over which either the permeability or permittivity is negative.

The metamaterial with the best performance, which has apertures consisting of almost circular 16-sided stars, has a continuous NRI bandwidth of 552 nm, or the band including wavelengths from 640 to 1192 nm. (The NRIs of pre-existing fishnet metamaterial designs have usually maxed out at around 100 nm.) This same structure with the 16-sided stars has a DNRI of 106 nm (a large DNRI is more difficult to achieve, but is more attractive because the resulting metamaterials have lower optical loss). Other star-aperture-based metamaterials have both continuous NRI and DNRI bands in the yellow and green visible regions.

Contact Shiwei Zhou at [email protected].