Photonics Applied: Optical Materials: Optical materials withstand assault from high-power ultrashort-pulse lasers

LAURENT GALLAIS

Short-pulse lasers (commonly called ultrafast lasers) have undergone rapid growth both in capability and application since the advent of chirped-pulse amplification. Initially driven by cutting-edge fundamental research, the development of femtosecond lasers is now interlinked with a large number of industrial metrology, research, and medical applications. Further, by enabling action on matter in a controlled way at the nanometer scale and by opening up the possibility of monitoring events with femtosecond resolution, ultrafast lasers have provided physics, chemistry, and biology with research tools of unexpected power.

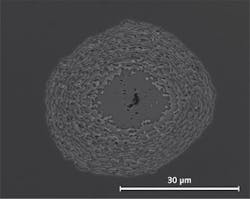

Generating and manipulating such femtosecond laser pulses require specific optical components that have, for instance, the ability to limit pulse lengthening and spectral distortion. Today, the peak-power-handling capability of these optical components can inhibit the evolution of high-power, high-performance ultrafast laser systems (see Fig. 1).1

Experimental measurements of the laser-induced damage threshold (LIDT) of optical materials are mainly of interest to identify the proper optical materials needed for fundamental ultrafast laser research. This LIDT information can be used for the design of optical components or for comparison with theoretical models.

Unfortunately, published LIDT data is difficult to compare because laser damage measurements are often made in different conditions and can be a source of discrepancies. Consequently, the objectives of our work at Institut Fresnel are 1) to compare the laser-damage resistance of optical materials (bulk and thin films) characterized and damage-tested in similar conditions and 2) to discuss the dependence of LIDT on laser operational conditions-such as wavelength, pulse duration, and number of pulses-based on state-of-the-art measurement techniques.

Dielectric bulk and coating materials

In the case of dielectric materials, the damage of the material is the result of a sequence of events that can be separated in time. First, when a dielectric material is irradiated by a pulse with very high peak power (1 J/cm2 at 100 fs corresponds, for example, to a maximum intensity of 10 TW/cm2), the physical processes of photoionization (PI) and impact ionization (II) of the material can result in an avalanche process. Depending on the irradiation conditions (wavelength, pulse duration), PI or II can be the dominant process; however, the result at the end of the femtosecond pulse is that the material will have a very high density of energetic free electrons.

As part of these ionization processes, the energy of the hot electron gas (being in a strong nonequilibrium state) will transfer to the lattice in a second step, a process that occurs on the time scale of a few picoseconds. Depending on the irradiation conditions and on the material properties, the local physical destruction of the material will then occur by thermal or mechanical effects in the nanosecond to microsecond time scale.

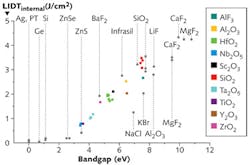

The physical mechanisms of energy deposition (II and PI) have an efficiency that depends directly on the bandgap the material. Thus, the LIDT is directly dependent on the bandgap value of the material (see Fig. 2).In the case of bulk materials, fluorides have better laser damage resistance than oxides. Of course, semiconductor materials have a very low damage threshold. For thin-film materials, a clear linear scaling of the breakdown fluence with bandgap energy is observed for a large range of materials. However, the LIDT is not dependent on the deposition technique; for example, the low dispersion results for different hafnium oxide (HfO2) samples correspond to samples made with different techniques such as evaporation and sputtering.

In the case of material mixtures (co-deposition of several oxides or oxides and fluorides), more complex dependencies are observed.2 The choice of an optical material in these conditions could seem obvious as far as damage resistance is concerned, but as we will detail in the following section, other considerations such as "incubation" or "fatigue" effects need to be taken into account.

Metal films

Mirrors for ultrashort high-power laser applications require high reflectance over a large bandwidth and low absorption. Metal films, especially gold layers, play a significant role as mirrors in ultrafast laser systems. These materials can withstand fluence values up to the point where enough energy is deposited in the materials to induce damage.

Since thermal processes are involved for pulses shorter than 1 ps, the heat has no time to diffuse out of the irradiated area and only the energy density matters. This implies that the damage threshold is not dependent on the pulse duration, and for very short pulse durations (< 20 fs) metallic mirrors have comparable LIDT to highly reflective dielectric stacks.

The most common metals that can be used for optical coatings are gold, silver, copper, platinum, nickel, and aluminum. While aluminum has good ultraviolet, visible, and far-infrared reflectance, the reflectance of aluminum drops significantly at 700–900 nm wavelengths. Also for nickel and platinum, the reflectance is too low for reflective-mirror applications.

Silver is one of the most commonly used metals in optical applications due to its high reflectance and ease of evaporation, though there are oxidation issues upon atmospheric exposure.

Gold and copper have similar infrared spectral qualities and function well as infrared reflective coatings beyond 700 nm. On glass, gold tends to form rather soft, easily damaged films, but a film of chromium or nichrome can solve this problem and make gold adhere strongly to the substrate. Energetic deposition processes can also improve the adhesion of gold on glass.

From a laser damage resistance point of view, gold and silver should be preferred to copper based on physical properties of the materials. However, given the lack of available experimental data on these two materials, it is difficult to conclude whether gold or silver have better laser-damage resistance, although values around 1 J/cm2 have been reported.3,4 Furthermore, the damage resistance is dependent on film thickness: the thicker the film, the higher the LIDT because "hot" electrons can diffuse better within a deeper film.

Dependence on laser operational parameters

Based on empirical work and theoretical studies, some scaling laws of LIDT dependence as a function of operational parameters of the laser (pulse duration, wavelength, polarization, repetition rate, number of pulses, and spot size) can be derived. This is very useful for practical applications when an optical component has been qualified in one set of conditions and needs to be applied in a different set. Three particular laser parameters that are linked to optical damage effects include laser pulse duration, wavelength, and the number of pulses.

In the case of dielectric materials, LIDT is approximately defined as Tk, where T is the pulse duration and k is a fixed parameter with a value of ~0.3.5 This Tk relationship has been found to be independent of the material and is attributed to the process of photoionization-seeded avalanche ionization. For metals, however, as discussed previously, LIDT is independent of the pulse duration in the femtosecond to picosecond range.

Regarding laser wavelength, the ionization of optical materials is the consequence of nonlinear processes as previously discussed. These processes involve the simultaneous absorption of several photons: the more photons needed to overcome the bandgap energy of the material, the less efficient is the process. Therefore, when the photon energy is increasing (wavelength is decreasing), less energy is required and LIDT typically decreases.

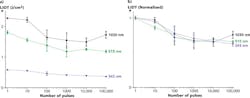

In the case of multiple pulses, the damage threshold decreases with the number of pulses in the process called incubation or fatigue. This decrease in damage resistance is directly related to the number of incident pulses, but also on other irradiation parameters such as the pulse duration, and possibly, repetition rate.6 The decrease in damage resistance can reach more than 50% for some materials. The process involves dependence on native defects (related to the fabrication method) and on laser-induced electronic defects (related to irradiation conditions) (see Fig. 3). Extensive systematic studies are still needed on this point to quantify this pulse-dependent behavior for a particular material.In summary, performance of single bulk and thin-film optical materials can be ranked based on their bandgap values with a linear evolution of the LIDT. Accordingly, deposition parameters are not critical, at least for single-pulse irradiation. For mixed films, however, more complex behavior is observed. Moreover, in some cases the combination of the materials gives specific properties to the film, and high damage threshold can be achieved. Metal films, particularly silver and gold, are suitable for high-power applications in the case of very short pulses (sub-20 fs) because their LIDT values are comparable to dielectric materials. Overall, however, the user must consider incubation or fatigue when an optic is submitted to multiple subpicosecond irradiations. Finally, LIDT is strongly dependent not only on the material of choice, but also on its fabrication merit.

References

1. L. Gallais et al., Opt. Lett. 39, 6, 1545–1548 (2014).

2. L. Gallais and Mireille Commandré, Appl. Opt., 53, 4, A186–A196 (2014).

3. B. C. Stuart et al., J. Opt. Soc. Am. B, 13, 2, 459–468 (1996).

4. B. Wang et al., Opt. Exp., 21, 12, 14698–14711 (2013).

5. M. Mero et al., Phys. Rev. B, 71, 11, 115109 (2005).

6. M. Mero et al., Opt. Eng., 44, 5, 051107 (2005).

Laurent Gallais is associate professor at Institut Fresnel, Aix-Marseille University, Centrale Marseille, Campus Universitaire de Saint Jérôme, Avenue Escadrille Normandie-Niemen, 13397 Marseille, France; email: [email protected]; http://www.fresnel.fr/spip/.