UV Lasers: Injection-lock technology fires 450 mm excimer laser lithographic engine

HITOMI FUKUDA

In the semiconductor manufacturing industry, there are growing concerns over future environmental impact as enormous fabs expand and new generations of equipment become larger and more powerful. To address these concerns, Gigaphoton has implemented various green initiatives for many years under its EcoPhoton program, such as the GigaTwin ultraviolet (UV) lithography laser platform based on injection-lock technology.

GigaTwin injection-lock technology reduces electricity and gas utilization of the laser by up to 50%. Together with other technical advances, injection-lock technology enables our laser system to be technically and ecologically viable for high-volume, 450 mm semiconductor wafer manufacturing.

450 mm wafer production challenges

Today, 193 nm UV argon fluoride (ArF) excimer lasers are widely used in wafer volume production below the 45 nm node. For the 32 nm node and beyond, this technology can be applied not only for immersion lithography but also for such advanced lithography technologies as multipatterning lithography. These lasers are considered the mainstream solution until extreme ultraviolet (EUV) lithography is ready.

With next-generation process technologies such as 450 mm wafer production, as the wafer size increases, so does the number of die. In turn, the laser pulse width used for each die will need to decrease due to mechanical limits, reducing throughput.

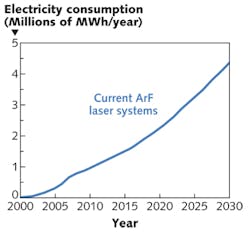

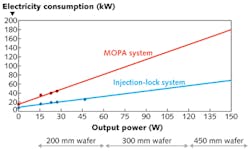

To increase throughput, the stage speed of the scanner must be improved, as well as the output power from laser light sources. Although the simplest way to increase laser output power is to increase input electricity, continuously increasing electricity consumption to generate more power is not a practical solution for high-volume manufacturing (HVM) environments (see Fig. 1).1 Instead, technical innovations are required to maximize laser efficiency to generate more power using less electricity.

Another demand for next-generation lithography is higher resolution, where excimer-laser-light sources are required to produce narrow-spectrum light. However, when power is increased, the spectrum width tends to widen.

Injection-lock architecture

Injection locking is a newer approach to a twin-chamber laser system and offers some advantages over master oscillator power amplifier (MOPA) systems widely used in lithography equipment.

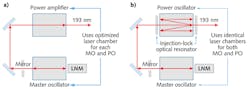

In a traditional MOPA system, the master oscillator laser chamber generates a narrow spectrum seed light through an optical resonator consisting of a line-narrowing module (LNM) and a mirror (see Fig. 2). This light is then fed into the power-amplifier chamber, where the power is amplified through a single-pass or double-pass amplification process. Both the master oscillator and the power oscillator typically require laser chambers that are optimized for each purpose. In this case, the effective gain duration for amplification is limited to around 6 ns based on the relationship between gain length (100 cm) and the speed of light (30 cm/ns).In the GigaTwin injection-lock technology platform, the same laser chambers are used for both laser oscillation and amplification. The narrow-spectrum seed light is generated by the master oscillator using the same process and technology as the MOPA systems; however, light is then injected and locked in a power oscillator as opposed to a power amplifier.2

The injection-lock process in the power oscillator improves optical and electrical performance by injecting light with a particular frequency into the laser resonator, amplifying the light without affecting the width of the spectrum. To obtain high-power, narrow-bandwidth radiation, an oscillator-regenerative amplifier system is used for high-efficiency, high-spectral-brightness amplification.

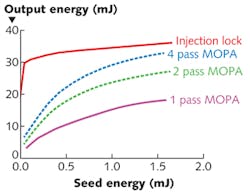

In this system, a regenerative amplifier with a pair of optical resonators (front/back mirror) is used. The seed beam generated from the master oscillator is injected through the back mirror, and the laser beam is regenerated by the round trip between two mirrors during the excitation lifetime of the dimer used (approximately 20 ns), which is equivalent to six-pass amplification. This is how the injection-lock system yields higher output energy efficiency compared to four or more passes in traditional MOPA systems (see Fig. 3).GigaTwin evolution

Gigaphoton released the first injection-locked GT60A ArF excimer laser to the ArF immersion market in 2006. With 60 W power, 6 kHz repetition rate, and 0.5 pm spectral bandwidth using an E95 metric (defined as the width of the spectrum containing 95% of the integrated spectral intensity), the GT60A has since evolved into the second-generation GT61A with narrower 0.3 pm spectral bandwidth for high numerical aperture (NA) lithography at the 45 nm node.

The 6 kHz, 0.3 pm GT62A is a higher-throughput model with 90 W power and a high-precision E95 measuring module and stabilization control system optimized for double-patterning lithography at the 32 nm node. It includes a variety of technologies designed to reduce laser operation costs and is backward compatible with previous GigaTwin series lasers. Released in 2012, the GT63A has identical output power, repetition rate, and spectral bandwidth as the GT62A, but is also suitable for multipatterning lithography and contains functionalities that enhance data monitoring, lengthen module lifetime, and optimize the gas refill process.

Introduced last year, the GT64A (6 kHz/0.3 pm at E95) can produce variable power outputs ranging from 90 to 120 W for multipatterning in 450 mm wafer production applications. Power output is automatically optimized based on the scanner's requirements and the customer's process. Its stable energy, spectral bandwidth, and beam profile, combined with longer pulse durations, improves overlay accuracy, critical dimension control, and minimizes line-edge roughness in semiconductor wafers-all of which are extremely important for multipatterning lithography.

Injection-lock laser performance

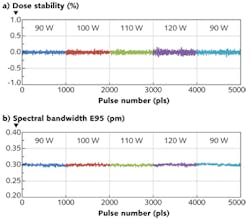

Energy dose stability, defined as the change rate of integrated energy value between each moving window of specified repetitive pulses, is an important property of laser output because it affects critical dimension wafer uniformity. For the GigaTwin platform, there is minimal difference in energy dose stability when the laser is operated at power levels from 90 to 120 W (see Fig. 4).3Spectral bandwidth is also an extremely important factor for lithographic imaging capability towards smaller wafer feature sizes; for GigaTwin, the E95 spectral bandwidth of 0.3 pm is extremely stable for various output power levels from 90 through 120 W operation.

Finally, as ArF immersion lithography moves into high-volume production, reliability of the laser is a primary industry concern. An important measure of reliability is the laser's "availability." Availability is defined as the percentage of the system's available time versus the total operation time and is calculated as total hours of operation minus scheduled and unscheduled downtime divided by total hours of operation. An evaluation of the reliability of 175 lasers based on the GigaTwin platform with injection-lock technology reveals an average availability exceeding 99.5%.

Survey data collected from actual customer production sites indicate that the actual electricity consumption of 120 W injection-lock technology systems is almost half that of MOPA systems under current 450 mm wafer manufacturing conditions (see Fig. 5). A further benefit gained by this efficiency is gas usage reduction. When less electricity is used, the gas deterioration rate is correspondingly smaller; therefore, applying injection-lock technology enables a 50% reduction in both electricity and laser gas usage. To further improve gas efficiency, an advanced gas-management system optimizes the gas injection amount based on laser performance, further reducing gas consumption by another 50%.Gigaphoton's EcoPhoton effort focuses on creating innovations that improve "green" operations through reduced materials and energy consumption. A new hybrid laser system that uses a solid-state laser is under development that will further improve efficiency, requiring almost half the amount of electricity needed to operate our already green current-generation UV ArF laser systems.

REFERENCES

1. Takashi Onose et al., "Development of hybrid ArF laser system for lithography," SPIE Photonics West 2013, San Francisco, CA, paper no. 8607-51.

2. Hitomi Fukuda et al., "Advanced excimer laser technologies enable green semiconductor manufacturing," Proc. SPIE 9052, 90522J (2014).

3. Takeshi Asayama et al., "Power up: 120 W injection-locked ArF excimer laser required for both multi-patterning and 450 mm wafer lithography," Proc. SPIE 8683, 86831G (2013).

Hitomi Fukuda is from the marketing team at Gigaphoton, 400 Yokokurashinden, Oyama-shi, Tochigi-ken 323-8558, Japan; email: [email protected]; www.gigaphoton.com.