Lidar: Single-photon lidar yields rapid topographic and bathymetric coverage

In September 2011, Laser Focus World described the capabilities of a single-photon-sensitive light detection and ranging (lidar) system developed by Sigma Space Corporation (Lanham, MD). Passing a low-power, high-repetition-rate 532 nm green laser beam (140 mW at 20 kHz) through a diffractive optical element (DOE) generated a 10 × 10 array of low-power (1 mW) beamlets and allowed surface measurement rates up to 2 megapixels per second (Mp/s).

This early system generated (in a single overflight) contiguous high-resolution 3D topographic images of low-reflectance tree canopies and high-reflectance cryospheric surfaces from altitudes above ground level (AGLs) of 1 and 2.5 km (3.3 and 8.2 kft), respectively, while traveling at a maximum speed of 88 knots (161 km/hr). With a maximum swath of 0.5 km at 1 km altitude, this limited areal coverage to around 80 km2/hr. Today, Sigma’s improved single-photon-sensitive lidars operate at AGLs up to 8.5 km (28 kft) with swaths up to 2.5 km.1

Hercules

The primary technical goal of Sigma’s recently introduced, self-funded, moderate-altitude high-resolution quantum lidar system (HRQLS; pronounced Hercules) is to allow large areas to be mapped quickly while still permitting the user to tailor the measurement point density. Areal coverage is equal to the product of swath and air speed; to increase the swath relative to earlier systems, the HRQLS dual-wedge optical scanner produces a larger maximum half-cone angle of 20º while—in parallel—an order-of-magnitude increase in laser power to 1.7 W allows the system to operate at higher altitudes. Thus, at a nominal AGL of 2.3 km (7.5 kft), where the probability of detecting a 10% reflectance surface is 95%, the swath is 1.66 km.

The HRQLS laser also has a slightly higher 25 kHz repetition rate and, with the same 10 × 10 beamlet array, permits up to 2.5 Mp/s measurement rates. A 7.5 cm aperture receiver system shares the scanner with the transmitter. The scanner is also designed to maintain the alignment between the transmitter and receiver field-of-view (FOV) by compensating for speed-of-light effects at all operating AGLs greater than 2 km.

The HRQLS lidar system produces a 5 × 5 m array of spots on the ground at the nominal 2.3 km AGL, resulting in a ground-pixel dimension of 50 cm. For the nominal 2.3 km AGL, maximum half-cone angle of 20º, and maximum airspeed of 450 km/hr, the maximum areal coverage is 616 km2/hr, almost 8X that of the earlier system. Under these operating conditions, the worst-case point density is 8 m-2 along the ground track (resulting from only two looks at the same 1 m2 parcel in the fore and aft phases of the scan), while the mean point density within the overall scan is 13 m-2.

Larger swaths and areal coverage can be achieved by flying at higher altitudes (up to 18 kft) but with reduced point densities. Smaller swaths with high-point densities can be achieved by adjusting the relative phase of the two wedges via software to yield a smaller conical deflection. Higher point densities at the larger swaths can also be realized by reducing the aircraft velocity at the expense of reduced areal coverage. The entire HRQLS system measures just 48 × 63 × 83 cm for a total volume of 0.25 m3.

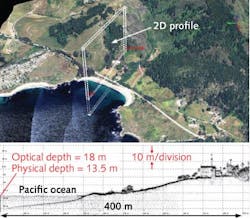

Sigma’s HRQLS was recently contracted to map all of Garrett County, MD, occupying about 1700 km2. The entire county was mapped in four flights totaling 12 hours of flight time that included a 50% overlap between flight lines as well as transit times to and from the host airport. Another set of flights aimed at bathymetry was conducted over the Pacific Ocean off Point Lobos near Monterey, CA, wherein HRQLS was able to see ocean-bottom depths just shy of 14 m (see figure).

“HRQLS is the next step in developing scanning single-photon lidars capable of operating at higher velocities and altitudes,” says John Degnan, chief scientist at Sigma. “We have already demonstrated a 100-beam single-photon lidar for a customer with comparable spatial resolution to HRQLS but operating at 200 knots from a much higher AGL of 8.5 km [28 kft] with a swath width of 2.4 km, and have developed feasible spaceborne concepts for contiguous and rapid global topographic mapping of our planet.”

REFERENCE

1 J. Degnan and C. Field, 2014 SPIE DSS, paper 9914-16, Baltimore, MD (May 2014).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.