Novel Lasers: Whispering-gallery-mode resonators create ultranarrow-linewidth semiconductor lasers

LUTE MALEKI

Spectral purity is a feature of an oscillator that allows discrimination of closely spaced frequencies. In the case of lasers, frequency noise and linewidth are usually considered as measures of spectral purity. In particular, narrow-linewidth lasers can be used in applications where high resolution in measuring a frequency (wavelength) difference is required.

Applications that require lasers with high spectral purity include: 1) those based on interferometric measurements, such as fiber optic sensors; 2) those that require long coherence length, such as light detection and ranging or LIDAR; and 3) those that require direct measurement of closely spaced frequencies, such as spectroscopy. Narrow-linewidth lasers are also required for coherent communications, where they serve as the local oscillator in an optical phase-lock loop (a particular type of interferometer).

In addition to spectral purity, narrow-linewidth lasers must also operate at particular wavelengths required in individual applications. In addition to using gas, solid-state, and fiber lasers to meet these applications, semiconductor lasers are also becoming viable candidates thanks to advances in linewidth-narrowing techniques.

Defining spectral purity

The use of linewidth as a measure of spectral purity is widespread in the laser literature, and many vendors specify it. This, however, is not a precise way to specify the spectral purity of the laser since the measured linewidth depends on the time scale (bandwidth) of the measurement. Most vendors, therefore, specify the instantaneous linewidth, which is essentially the Schawlow-Townes limit of the laser.

The best way to quantify spectral purity is to use power spectral density of phase noise, or frequency noise. This approach depicts the laser noise and its spectral purity across all Fourier frequencies of interest, typically ranging from 1 Hz to 100 MHz. For this article, the practice of laser linewidth will be used.

Another way to describe the property of spectral purity of a laser is by specifying its coherence length or coherence time. This is the distance (or equivalently, time of flight, as speed of light divided by the distance) through which the coherence properties of laser light are preserved.

As the length of an interferometer increases to approach the coherence length of the laser, the quality of observed fringes degrade and will ultimately disappear if the coherence time is not long enough. Thus, in applications such as sensing with interferometry, where light propagating through two arms are combined to observe a phase or frequency change (produced by an applied disturbance on one of the arms), the linewidth of the laser determines how long the length of the interferometer arm may be to make a measurement with a desired degree of resolution.

Application-specific wavelengths

Typically, interferometric, long-coherence-length, and spectroscopic applications require a narrow-linewidth laser at a specified wavelength. For example, most fiber sensors use lasers with wavelengths around 1550 nm, as do local oscillators for coherent optical communications; LIDAR could require other wavelengths down to the visible, or as long as around 2000 nm and longer. Spectroscopy has the greatest need for a wide wavelength range since atomic lines span the ultraviolet (UV) to near-infrared (IR) range, and molecular wavelengths are typically in the mid- to far-IR region.

In many applications, small size, weight, and robustness of the laser with respect to temperature, acceleration, and vibration are also required parameters. While the compactness and robust character of semiconductor lasers would ideally serve these spectrally pure applications, semiconductor lasers have inherently wide linewidth due to their tiny cavity size that must be narrowed by external means.

The most effective approach to reduce laser linewidth is with narrow-passband external filters and cavities. Advances in miniature Fabry-Perot cavities and Bragg gratings provide effective means for narrowing the linewidth of semiconductor lasers, either through feedback of filtered light to the laser or by locking the laser with electronics schemes such as the widely used Pound-Drever-Hall technique. These schemes also preserve the desirable features of semiconductor lasers including small size, low power consumption, robust operation, and low cost.

Unfortunately, conventional approaches to externally reduce the linewidth of semiconductor lasers suffer from three major shortfalls. First, the performance they produce does not match the subkilohertz linewidth of fiber and gas lasers—an important consideration as emerging approaches for sensing, LIDAR, and high-resolution spectroscopy require ever-increasing spectral purity. Second, available filters and cavities have limited operational wavelength range. Finally, externally line-narrowed lasers are often difficult to tune without mode hopping.

WGM resonators

In the past few years, OEwaves has developed ultranarrow-linewidth semiconductor lasers based on the use of miniature optical whispering gallery mode (WGM) resonators, circularly symmetric structures made of a transparent material and ranging in size from a few tens of microns to a few millimeters (see Fig. 1).1-4

These WGM resonators support modes with an extremely high quality factor (Q, defined as the ratio of the mode frequency over the mode bandwidth) that reside at the perimeter of the structure, close to the surface. In fact, one of the highest Q values and largest finesse ever reported with an optical cavity is with a calcium fluoride WGM resonator with Q = 3 × 1011, corresponding to a bandwidth of about 6 kHz and a finesse of 10 million.5

The high Q and narrow linewidth of these modes is due to structural loss mechanisms that can be made extremely small. These include bending loss that is negligible when the radius of curvature of the resonator is much larger than the wavelength of light and scattering loss that can be eliminated by appropriate processing of the resonator surface. The dominant loss mechanism in these resonators is material absorption, which is extremely small for crystalline materials such as calcium fluoride and magnesium fluoride. Resonators made with silica and silicon nitrite also exhibit fairly high Q values.

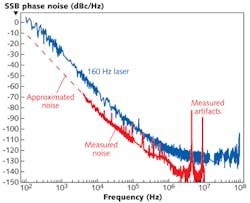

Our technique narrows the linewidth of semiconductor lasers via self-injection locking to a WGM resonator.6 This approach can reduce the linewidth of a distributed feedback (DFB) laser to about 10 Hz (see Fig. 2); recently, we have demonstrated a DFB laser with linewidth as narrow as 0.6 Hz. Significant linewidth narrowing of Fabry-Perot semiconductor lasers to a few-hundred hertz has also been demonstrated.Self-injection locking uses the light reflected back from the resonator due to scattering by small internal scattering centers to collapse the linewidth of the laser.7-10 In addition, self-injection locking stabilizes the dynamics of the laser, reducing mode hopping and improving polarization stability.

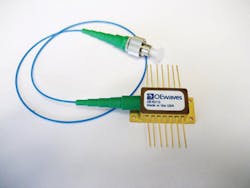

The small size of the resonator and direct coupling with the laser chip allows integration in a typical butterfly package with approximate dimensions of 2.5 cm × 1.2 cm × 1.2 cm (see Fig. 3). Fully turnkey 10 mW, <300 Hz linewidth laser modules including all electronic circuits—that can be amplified in power without degradation of performance—are basically the size of an iPhone.Since the transparency of the resonator material covers the UV to far-IR wavelength range, our approach can produce ultranarrow-linewidth coherent light at any wavelength for which a semiconductor laser is available; lasers with linewidth <300 Hz have been produced at 685, 795, 1030, 1550, 2000, and 4500 nm for a variety of LIDAR, sensing, and atomic and molecular spectroscopy applications.

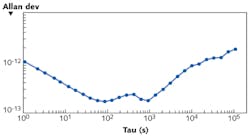

By changing the temperature of the resonator, these lasers can achieve a 2 nm tuning range with continuous, mode hop-free tuning across 50 GHz. Lasers can be modulated at 100 kHz rates with modulation depths in excess of 3 GHz by combining a piezoelectric (PZT) element with the resonator to change the mode frequency through applied stress. These lasers are particularly useful in LIDAR applications where narrow linewidth must be combined with the ability to modulate the laser frequency rapidly and with large modulation depths.Using the fast modulation feature, we have locked a laser to the 795 nm optical D1 transition in rubidium atoms by held in a tiny vapor cell. The stability performance of this laser as shown in an Allan deviation plot is 10–12 at 1 s and reaches a value of <2 × 10-13 at an averaging interval between 100 and 1000 s (see Fig. 4). The entire package containing the laser and the cell is only 10 cm × 5.5 cm × 2 cm in size—smaller, lighter, and more energy efficient than competing fiber, gas, and solid-state lasers with this performance.

REFERENCES

1. W. Liang et al., Opt. Lett. 35, 16, 2822–2824 (2010).

2. V. S. Ilchenko et al., Proc. SPIE 7913, 79131G (2011).

3. Danny Eliyahu et al., Proc. SPIE 8960, 89600X (2014).

4. L. Maleki et al., Chapter 3 in Practical Applications of Microresonators in Optics and Photonics, ed. A. B. Matsko (CRC Press, 2009).

5. A. A. Savchenkov et al., Opt. Express 15, 6768–6773 (2007).

6. US Patent No. 7,991,025; US Patent No. 7,869,472.

7. B. Dahmani et al., Opt. Lett. 12, 876–878 (1987).

8. L. Hollberg and M. Ohtsu, Appl. Phys. Lett. 53, 944–946 (1988).

9. A. Hemmerich et al., Appl. Opt. 33, 988–991 (1994).

10. V. V. Vassiliev et al., Opt. Commun. 158, 305–312 (1998).

Lute Maleki is president and CEO of OEwaves, 465 N. Halstead St., Suite 140, Pasadena, CA 91107; e-mail: [email protected]; www.oewaves.com.