The technology behind thin-film multilayer high-reflection coatings, widely used on optics for use in the UV through IR wavelength ranges, can be pushed, and pushed hard.

Researchers at Lawrence Livermore National Laboratory (LLNL; Livermore, CA), the University of Denmark (Lyngby) and the European Synchrotron Radiation Facility (Grenoble, France) have created very-short-period multilayer coatings deposited on superpolished substrates that are designed for use with soft gamma-ray photons.

The researchers’ efforts have resulted in grazing-incidence-reflection coatings that reflect photons with energies up to 0.65 MeV (about 0.002 nm wavelength), which is almost two times higher than the previous record of 384 keV set by the same group in 2013.

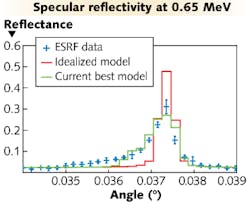

The researchers used a common approach for creating short-wavelength mirrors (such as x-ray mirrors): designing for grazing-incidence angles. This does three things: first, it raises material reflectivity, which depends on incidence angle; second, it spreads optical power across a larger area of the mirror; and third, it increases the layer thickness for Bragg reflection. In the case of 0.65 MeV gamma rays, a normal-incidence half-wave thickness on the order of 0.001 nm is increased to a more-manageable nanometer scale. In the experiment, the chosen grazing-incidence angle of 0.0375° at 0.65 MeV photon energy enlarged the 65 μm beam height to a 110 mm beam footprint along the mirror for the first-order Bragg angle reflection. The coating itself consisted of 300 layer pairs (tungsten carbide and silicon carbide) with a 1.5 nm period (having a 4% peak-to-valley variation) on superpolished quartz. Such gamma-ray grazing-incidence coatings can be applied to toroidal substrates to create focusing gamma-ray optics for astronomy and physics research. One example of an astronomical application is the cosmic mapping of the very important electron-positron annihilation line at 0.511 MeV. Angular reflectivity data were taken at the European Synchrotron Radiation Facility (ESRF; Grenoble, France). Contact Nicolai F. Brejnholt at[email protected].