TiO2 nanoparticles reach visible spectrum with simple doping technique

Nontoxic, chemically stable, and relatively inexpensive-to-fabricate titanium dioxide (TiO2) semiconductor nanoparticles are of broad interest as photocatalysts, and, when doped with vanadium (V), become active in the visible spectrum for applications in dye-sensitized solar cells and possible illumination/sensing applications. Unlike existing immersion, solgel, and hydrolysis-based V-doping processes that are expensive and complex, researchers at the University of Puerto Rico (San Juan, Puerto Rico) have developed a simple doping technique that reduces the bandgap and increases the photo-quantum yield of TiO2 nanoparticles, allowing them to cost-effectively achieve visible-spectrum operation.

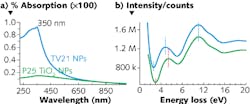

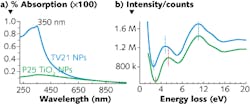

In the synthesis method, commercially available TiO2 nanoparticles were added to varying molar solutions of vanadium oxalate (VOC2O4) created in a simple chemical reaction between low-cost vanadium oxide (V2O5) microparticles and readily available oxalic acid (H2C2O4). Several samples were prepared by varying the Ti:V ratio (1:1, 2:1, and 8:1 corresponding to samples TV11, TV21, and TV81, respectively). The V-doped nanoparticles were examined using transmission electron microscopy; from electron-energy loss spectra (EELS), a reduction in the bandgap of 0.5 eV (about 20% less than the nominal 3.03–3.2 eV) was measured for sample TV21 compared to undoped pure TiO2 nanoparticles (sample P25)—a 2.5X improvement over other doping methods. This bandgap reduction enables increased ultraviolet/visible absorption. Contact Maxime Guinel at[email protected].