LC retarder helps lidar measure both wind-velocity magnitude and direction

Inexpensive wind-sensing lidars based on continuous-wave (CW) narrow-linewidth laser-diode light sources are becoming useful to the wind-energy industry as anemometers. Now, researchers at the technical University of Denmark (Taastrup) have added a liquid-crystal retarder (LCR) to such a device to extend its capabilities from simple radial wind speed (scalar) sensing to wind-velocity measurements, in which both the magnitude and direction (vector) of the wind velocity are measured. The LCR adds vector measurement by nonmechanically switching the beam direction between two states with a 60° angular separation.

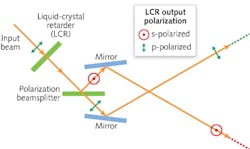

In the lidar’s optical system, the LCR is paired with a polarization beamsplitter; the LCR itself can rotate the incoming beam’s polarization so that it either passes through or is reflected from the beamsplitter. Mirrors direct the two switched beams so that they project outward at 60° from one another. The LCR can switch between polarization states in one direction at a speed of 100 μs, and in the other direction at 16 ms, resulting in windspeed measurements being taken at a 33 Hz rate. The lidar, called the “WindEye,” can measure wind velocity magnitude and direction to better than 0.1 m/s and 1° resolution, respectively, say the researchers. They are now testing the WindEye against other types of anemometers over a period of months and under varying weather conditions. Reference: P.J. Rodrigo et al., Opt. Express 22, 22, 26674 (Nov. 2014); doi:10.1364/OE.22.026674.