Photonic Frontiers: Optics: Looking back/Looking forward: A transformation of optical components

I discovered optics when my father gave me a one-inch Wollensak refracting telescope in the early days of the space race. The Edmund Scientific catalog followed, and I saved my allowance to buy surplus optics.

Optics seemed new and fascinating, but in reality it was a sleepy backwater of technology when the laser was born in 1960, and largely remained so when Laser Focus published its first semimonthly issue on January 1, 1965. My surplus polished-glass lenses dated back to World War II, and Wollensak had made similar telescopes in the 1930s. Plastic contact lenses were newer, but the only plastic optics I saw were toys.Thin-film coatings and exotic materials

The first issue of Laser Focus concentrated on lasers, but the January 15 issue described "nearly perfect" laser mirrors with reflectivity more than 99.5% across the visible spectrum. D. E. Perry and Eugene Gordon of Bell Telephone Laboratories had deposited 35 dielectric layers, more than double the earlier record of 15 layers. That was important news because low-gain gas lasers needed high-reflectivity cavity mirrors to reach threshold.Optics had come a long way by the time I joined the Laser Focus staff in 1974. The August 1974 issue reported that the damage threshold of thin-film coatings had reached 3 to 4 joules/cm2 for 30 ps pulses. The December 1974 cover featured the new technology of adaptive optics, a mirror with an array of 21 piezoelectric transducers that shaped its flexible surface, described in a feature by Julius Feinleib of the Itek Corp. (Bedford, MA, but long defunct) (see Fig. 1).

Commercial optics had also advanced. In the same issue, Optical Sciences Group (San Rafael, CA) advertised Fresnel and spherical plastic lenses ranging from 3 mm to 3 ft in diameter (see Fig. 2). An ad from CVI Laser (Albuquerque, NM) offered optics of germanium, zinc selenide, potassium chloride, sodium chloride, and cadmium telluride for use with 10 μm lasers.

The April 1977 issue described diamond machining of metal mirrors, which the Lawrence Livermore National Laboratory used to make aspheric mirrors as large as 38 inches, including the 11.8 inch axicon shown on the issue's cover (see Fig. 3).

Optics in the 1980s

In an October 1984 review, Bob Shannon of the University of Arizona (Tucson, AZ) credited interferometric measurements with "the principle gains in productivity" in optics manufacturing over the past 25 years. He wrote that aspheric optics were "beginning to enter the production stage."

The New Products column of the April 1987 issue reported that Perkin-Elmer's Applied Optics Operations (Garden Grove, CA) had begun diamond-turning beryllium mirrors, attractive for space applications because of their light weight. Reflecting increased laser powers, Spawr Optical Research (Corona, CA) advertised copper mirrors to 24 inches with the "very highest damage threshold for your pulsed infrared laser." Janos Technology (Townshend, VT) advertised lenses, windows, beamsplitters, and mirrors made from 23 different materials to span wavelengths from the vacuum ultraviolet to the far infrared.

The 1980s also saw a new approach to big optics—spin-casting parabolic glass telescope mirrors. Our June 1988 issue reported that Roger Angel at the University of Arizona had spin-cast a 3.5 m mirror, and was building a furnace to make bigger ones. He cast the first successful 6.5 m mirror in 1992 and completed the first 8.4 m mirror, for the Large Binocular Telescope, in January 1997. But it took a set of tiny optics, designed and fabricated with exacting precision, to make the Hubble Space Telescope the world's premier eye in the sky despite its flawed primary mirror, as I reported in the February 1995 issue.

Commercial optics advanced apace. In the January 1995 issue, II-VI Inc. (Saxonburg, PA) advertised two-axis diamond turning of precision aspheric lenses and metal mirrors. Newport Corp. (Irvine, CA) advertised mirrors providing the full optical bandwidth and time resolution needed for ultrafast titanium-sapphire lasers. And AOtec, a subsidiary of the venerable American Optical Corp. (Southbridge, MA), advertised "glass quality from plastic lenses," a departure from AO's long focus on glass optics.

"The Year of WDM"

Strong demand for fiber-optic bandwidth offered by wavelength-division multiplexing (WDM) pumped up the market for narrowband filters. Herwig Kogelnik, director of Photonics Research at Bell Laboratories (Holmdel, NJ) proclaimed 1996 "the year of WDM" in our December 1996 issue. Multiplexing eight wavelengths sent 20 Gbits/s through a single fiber. In our March 1997 issue, the Optical Corporation of America (Marlborough, MA) described thermally stable WDM filters for the new 100 GHz (0.8 nm) dense-WDM channel spacing standard. After the turn of the century, DWDM systems became the backbone of the global telecommunications network.

In a series of other advances, metamaterials emerged from nowhere to become the cutting edge of 21st century optics, able to perform hitherto impossible feats, as described in our January 2005 issue. A research paper concluded a metamaterial with negative refractive index could achieve subwavelength resolution, but only in the near field. CVI Optical Components and Assemblies advertised optics for 193 nm water-immersion photolithography, which provides subwavelength resolution for making semiconductor chips. The world's fastest adaptive optics system was installed on the world's oldest super-telescope—the 200-inch Hale Telescope at the Palomar Observatory (San Diego, CA). And the laser marketplace had become global, with advertisers including HC Photonics (HsinChu City, Taiwan), providing a variety of periodically poled nonlinear optical materials, and Kaleido Technology (Farum, Denmark), offering precision-molded aspheric glass optics.

October 2014 saw the award of the Nobel Prize in Chemistry to Eric Betzig, Stefan W. Hell, and William Moerner for developing super-resolution fluorescence microscopy to overcome the limits of conventional optical microscopes. Special Optics (Wharton, NJ) said it was "excited to have made a small contribution" to Betzig's work by developing custom microscope objectives for his experiments.

New materials for future optics

Looking forward, Duncan Moore of the University of Rochester says the future of optical components "is going to be all about broadband," ranging from the ultraviolet to 14 μm for applications ranging from smartphones to military systems. Merely transmitting light is not enough; broadband optics should also be achromatic. "If you want a 10× zoom, you have some real challenges," says Moore.

StingRay Optics (Keene, NH) has developed a series of SuperBand lenses optimized for wavelengths from 0.7 to 5 μm, which combine materials to bring the whole band into focus, says company president Chris Alexay. StingRay Optics hopes to land a contract to develop a mid-infrared zoom lens to handle both laser designation in the 1 μm band and imaging in the 3 to 5 μm band, avoiding the need for dual optical systems in drones.

The auto industry's interest in 8 to 12 μm thermal imaging has dramatically reduced prices for optics and sensors in that band, says Moore. BMW offers the BMW Night Vision system as a $2300 option to help drivers spot pedestrians or large animals in or near the road. FLIR offers a thermal camera accessory for the iPhone at $349. But with market volume smaller in the mid-infrared, Moore says good 3 to 5 μm cameras still sell for tens of thousands of dollars.

"I can't imagine a time when the industry has been more poised for new developments," says Alexay. He expects the Naval Research Laboratory (Washington, DC) to report a promising new family of materials at the upcoming SPIE Defense Security and Sensing meeting on April 20-24, 2015 in Baltimore.

A U.S. DARPA (Defense Advanced Research Projects Agency) project seeks to reduce cost, complexity, and weight of military optics by developing manufacturable graded-index (GRIN) lenses, which can route light along complex paths to fit into compact military systems. Surmet Corp. (Burlington, MA) is developing volume-manufacturing processes for GRIN lenses based on the polycrystalline ceramic aluminum oxynitride (AlON), which is transparent from the visible to beyond 5 μm and is so strong it is used for tank windows, says Moore.

Plastic optics and thin-film colors

"We're only in the second or third inning of where we want to go with plastic optics," says Al Kapoor, chairman of Syntec Optics (Pavillion, NY). Their biocompatibility has made them a big success in medical applications. Their low cost and light weight are attractive for reducing soldiers' loads in the field. Now new plastics are overcoming the 70°C limit of acrylic plastics. One material called ULTEM is usable to 170°C, which Syntec is developing for use in head-up displays expected in cars by 2016.The range of shapes continues to expand. "Aspheres were a big thing 10 years ago, but now we can do them easily," says Kapoor. Syntec is currently developing ways to make more complex, asymmetric, and non-rotationally-symmetric plastic optics (see Fig. 4). As optics get smaller and their profiles grow more complex, he says, "the advantages of plastics go up" because molding can mass-produce shapes not practical in glass. "Our work is starting to touch the consumer market," says Kapoor, citing augmented reality systems such as Oculus Rift, and Samsung's development of eyewear similar to Google Glass that projects images onto the optics. But challenges remain, including bonding lenses together to make achromats, applying coatings, and a limited range of refractive indexes.

The spread of digital imaging is opening a new range of applications for thin-film coatings-providing crucial "ground truth" for color in medical imaging, says Jennifer Kruschwitz of JK Consulting (Rochester, NY). Diagnoses depend on color, so medical imaging needs stable color standards. Thin-film coatings can provide that stability, and can be made on a micrometer scale for microscopic imaging. In 2014, DataColor (Lawrenceville, NJ) introduced a series of thin-film calibration color slides called ChromaCal.

Metamaterials and the future

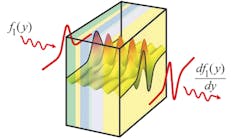

The allure of metamaterials is their tremendous potential for building optical materials to order, with otherwise unobtainable properties. Optical metamaterials remain in the laboratory stage, but two invited talks at the December 2014 Materials Research Society (MRS) meeting in Boston gave exciting visions of the future.In the first talk, Nader Enghata of the University of Pennsylvania (Philadelphia) said an impressive array of applications have already been demonstrated, including cloaking, superlenses, ultra-thin cavities, transformation optics, and metasurfaces. Then he went further. "Imagine a metamaterial that computes [see Fig. 5]. Could we design a material to get a derivative or an integral of a wave that you put into it?" He has been exploring the possibilities of optical "metatronics," metamaterials that conduct current and integrate optical and electronic functions, and his group is attempting to use one to take the second derivative of an input signal. In the long term, the group envisions an optical computational feedback loop.

In a second invited talk, Kevin MacDonald of the University of Southampton (England) argued for moving beyond widely used metallic metamaterials. "We can do better with all dielectric opto-mechanical metamaterials; we want to avoid losses associated with metals and create much stronger optical forces between resonators," he told the MRS meeting. He also envisioned moving beyond today's static metamaterials to active metadevices, and perhaps ultimately to metastructures that could be reconfigured by changing the applied electromagnetic field.

How many of these bright visions are attainable in the next half-century? If the past is any lesson, we overrate some ideas and are surprised by some unexpected successes. But we can safely say that the future of optical components is not likely to be a sleepy backwater.

About the Author

Jeff Hecht

Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.