Ultraviolet LEDs: UVC LEDs enable cost-effective spectroscopic instruments

A key trend driving overall market growth and innovation in spectroscopic instrumentation is the need for cost-effective instruments. Less costly, "lite" versions of instruments allow manufacturers to increase their product penetration to existing customers by offering lower-cost devices tailored for initial sample evaluation or for monitoring specific compounds.

In life-science laboratory environments, these lite instruments can be stationed at benches throughout the organization to increase productivity and reduce lab bottlenecks. End users employ the results of initial sample evaluation to determine whether further analysis is necessary by traditional full-spectrum instruments.

Wavelength-specific ultraviolet (UV) instruments that use LEDs instead of UV lamps offer affordable, compact instrument designs that consume less power. In environmental monitoring, for example, this enables the development of battery-operated sensors for remote monitoring of water quality. LED-based instruments also allow manufacturers to address market segments that might otherwise avoid their products because of footprint, cost, or complexity of operation.

Following are a few examples in which the use of UV LEDs versus traditional UV light sources is compared for various spectroscopic applications.

HPLC: Replacing deuterium lamps with LEDs

High-performance liquid chromatography (HPLC) is a separation technique in which a sample mixture is introduced into a column; the distinct compounds of the mixture then pass through the column at varied rates due to differences in how they partition between the mobile phase and the stationary phase. Once detected, these components are analyzed using a UV spectrophotometer. HPLC is typically used for protein purification, routine process monitoring in pharmaceutical and beverage manufacturing, process quality control, and biotech research.

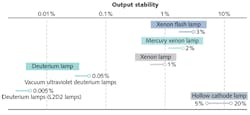

Current HPLC detectors typically use deuterium lamps as their primary light source due to their stable light output. This stability is characterized by measuring fluctuations in light output over short periods, such as the duration of a measurement. Using a UV light source with high light-output stability in HPLC ensures detection of lower concentrations of compounds. As seen in Figure 1, deuterium lamps are more stable than many UV lamp alternatives (for example, by almost two orders of magnitude over xenon flash lamps).

Engineers also prefer the long life of deuterium lamps, as well as the relatively high light output of the lamps at their HPLC-relevant UV wavelengths. Deuterium lamps, however, require a very stable power supply to maintain their performance and a warm-up period of up to 30 min to allow the lamp to reach thermal equilibrium. For this reason, most lamps are left on while not in use so that the instrument is ready as needed—wasting much of the lamp's useful life.

Newly available high performance deep ultraviolet (UVC) LEDs can provide better light stability than high-end deuterium lamps and offer more light output and useful life. UVC LEDs reach full stability instantaneously, unlike deuterium lamps. This allows end users to take complete advantage of the LED's lifetime, typically 3000 to 8000 h, depending on application conditions. In addition, UVC LEDs emit negligible front-side heat, which makes them ideal for heat sensitive samples.

With UVC LEDs, manufacturers can offer smaller, more cost-effective instruments for end users that require a single wavelength or a few fixed wavelengths. This evolution of low-cost, fixed-wavelength HPLC detectors will enable adoption in new applications such as caffeine detection in beverages and will increase penetration in applications such as prep HPLC of proteins.

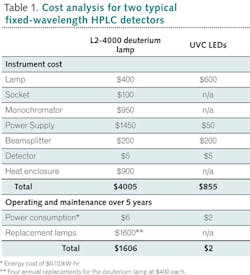

HPLC instrument cost analysis

Table 1 provides typical component and operating costs for a fixed-wavelength HPLC detector using deuterium lamps versus UVC LEDs. This illustrative example assumes detection for two fixed wavelengths and thus requires two UVC LEDs. Operating costs are estimated based on a typical laboratory operation where a deuterium lamp would be on 12 h a day, 52 weeks a year, and assumes 4 h of sample measurement per day. For this analysis, the instrument using the LED is turned on only when needed.

Ozone monitoring: Improved measurement performance

Commonly found air pollutants, or "criteria pollutants," include particulate matter, ground-level ozone, carbon monoxide, sulfur oxides, nitrogen oxides, and lead. Exposure to ozone, at even relatively low levels, is harmful to health and can result in reduced lung function and aggravation of pre-existing respiratory conditions. Considering that ozone is also used in industrial applications in processes as varied as semiconductor cleaning to water purification, monitoring ozone levels is critical. Countries in Europe and Asia have even taken measures to limit auto traffic in cities or to shut down factories in order to curb emissions in densely populated areas.

The current EPA ozone standard is set at a level of 75 ppb; this quantification of ozone in air is measured using UV absorption spectroscopy. Ozone monitors traditionally use mercury lamps as the light source for their measurement, as ozone has a strong absorbance at ~254 nm, the emission line of a low-pressure mercury lamp.

Typically, ozone concentration is determined with sequential measurements of the sample gas and zero gas that are fed alternately through a chamber; it is therefore important that the intensity of the light source be stable between the two measurements. The mercury-xenon lamps that have been traditionally used have higher power consumption and lower stability of light output than other UV light sources (as seen in Fig. 1).

Newly available UVC LEDs provide the high power output and spectral quality required for trace detection of pollutants at the parts-per-billion level to comply with government regulations. This allows end users to achieve more accurate measurements and benefit from the instant on/off nature of LEDs.

Other inherent benefits of LEDs make them attractive light sources for these instruments. UVC LEDs use direct-current (DC) power, operating from 6 to 10 V depending on drive current, which allows remote or handheld instruments to be battery or solar operated. This, coupled with the compact size of the LED, can lead to instruments that are up to 60% smaller than those using mercury lamps. UVC LEDs are a nontoxic source of ultraviolet radiation-unlike mercury lamps, which contain hazardous waste.

In addition, international agreements and regulations, such as the Minamata Convention, are aimed at reducing mercury pollution. (The Minamata Convention on Mercury, a global treaty to protect human health and the environment from the adverse effects of mercury, was agreed upon at the fifth session of the Intergovernmental Negotiating Committee in Geneva, Switzerland, on January 19, 2013. See www.mercuryconvention.org.)

Manufacturers are looking for alternatives to mercury lamps to address these legislative changes. By migrating from mercury lamps to UVC LEDs, engineers can reduce the footprint, power consumption, and environmental impact of their instruments without sacrificing measurement accuracy.

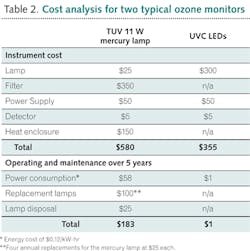

Cost analysis of a typical ozone monitor

Table 2 provides typical component and operating costs for an ozone monitor for fixed-wavelength detection at 255 nm using mercury lamps versus UVC LEDs. The operating costs are estimated based on a typical real-time monitoring application where the mercury lamp would be on 24 h a day, 52 weeks a year, and the LED is operated continuously at a 10% duty cycle. Note that the mercury lamp is kept on continuously to avoid both the slow warm-up time and lifetime degradation with on/off cycles.

Tracking water quality with LEDs

Water purity is a major concern for developed and developing nations alike, with hydraulic fracturing ("fracking") and possible effects of climate change highlighting water-quality concerns. The impact of natural events, such as rainfall and accompanying runoffs, and industrial water treatment are increasingly felt in water-distribution networks across the world. Rapid detection of changes in water quality is critical to ensure consumer health and environmental preservation.

Wastewater treatment plants and industrial facilities monitor influent and effluent water quality for productivity, effectiveness, and compliance with regulatory requirements. The collection of ongoing, real-time data on contaminant levels can decrease the response time to potential quality issues from days to hours. This depends on the use of autonomous water monitors—ones that need to be compact and cost effective—that continuously test water quality at multiple locations along the network.

Typical causes of changes in water quality include natural events, such as flooding, accidental discharge or spills, or other sources of contamination. UV photometry provides quantitative analysis of the organic content in water. By using continuous spectroscopic measurements instead of intermittent chemical testing with grab samples, end users gather process information, detect issues in water quality, and make the necessary process changes in real time.

Traditionally, these water-quality measurements have used xenon flash lamps as the light source for spectroscopy. Xenon flash lamps provide a broad spectrum of wavelengths and often require an expensive photodiode array for detection. These lamps also require an expensive power supply to maintain lamp performance. Although these high-quality instruments offer precise, accurate measurements of multiple parameters of water quality, they are often more than what a typical water facility requires. The associated costs are also restrictive to small water utilities, and unreasonable for developing regions.

Engineers can achieve the same benefits of xenon flash lamps for a subset of parameters by using UVC LEDs, along with a less costly detector and power supply. Newly available high-performance UVC LEDs offer linearity of measurement that matches the performance of expensive xenon flash lamps. This parameter refers to the correlation between the optical method of water-quality measurement with a reference method (typically a chemical measurement in the lab). A more compact, less costly instrument can thus become accessible to a wider cross-section of the market. Additionally, the reduced size and low power consumption of these instruments open possibilities for remote monitoring.

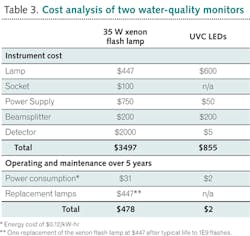

Cost analysis of a typical water-quality monitor

Table 3 provides figures for the typical cost of a broad-spectrum xenon flash-lamp-based monitor versus a wavelength-specific LED version. The UVC LED instrument assumes fixed wavelength detection at two wavelengths: 255 nm for the standard UV254 measurement and a second UV wavelength depending on the water-quality parameter of interest. Operating costs are estimated based on a typical water-quality measurement where the light source would be used for continuous measurement at a duty cycle of 1% (1 ms on, 100 ms off).

Cost-effective, compact instruments for the future

Traditionally, instrument designs that used UV lamps could take advantage of the benefits of the lamp, but unavoidably had to make concessions in instrument design due to limitations of the light source. High-performance UVC LEDs now enable design engineers to address market pressure for lower-cost products with instruments tailored for applications in life sciences and environmental monitoring.

By transitioning to UVC LEDs, instrument manufacturers can reduce instrument costs by 40% to 80%. These cost savings continue at the customer site due to a large reduction in operating and lamp-replacement costs over a five-year period. In addition, these "lite" instrument versions can capitalize on the instant on/off, low power consumption, and high-sensitivity features of UVC LEDs for better performance.

About the Author

Hari Venugopalan

Director of Global Product Management

Hari Venugopalan is director of global product management at Crystal IS (Green Island, NY).