Standoff Raman spectrometer identifies liquids in gas pipelines

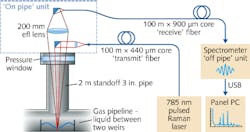

Natural gas is processed to remove water vapor, carbon dioxide, and hydrogen sulphide by injecting liquids into the gas stream. The liquids must then be removed from the natural gas before the gas is piped to its destination, or else the liquids can severely damage compressors and other parts of the gas transmission system. Such liquids must be rapidly and effectively detected and identified at transfer points in the gas distribution network. Engineers at IS-Instruments (Kent, England) and IMA (West Yorkshire, England) have developed a standoff Raman spectrometer for just this purpose, which allows sensing from 2.4 m away at standard 2-m-height standoff pipes in the network.

To contend with the weak nature of the Raman response, the group developed a high-etendue spectrometer that could collect as many photons as possible. The instrument, which is in a Michelson interferometer configuration (with gratings replacing the mirrors) with the probe light delivered to the gas pipe and the signal collected via optical fibers, forms a spatial fringe pattern that is Fourier-transformed to get the spectral information. Due to the design, the spectrometer has an etendue more than 100 times that of traditional dispersive systems. The researchers note that, unlike a conventional Fourier transform spectrometer, their device has no moving parts. The instrument was mounted 40 m away from the pipeline, with the optical fibers running to the measurement location. It was successfully tested against five different liquids: xylene, methanol, triethylene glycol, monoethylene glycol, and compressor oil, with liquid sample depths of 2 to 20 mm. The spectrometer is now ready for full integration onto an active pipeline. Reference: M. Foster et al., Opt. Express 23, 3 (Feb. 2015); doi: 10.1364/OE.23.003027.