Optical Materials: CVD diamond extends Raman laser capabilities

ANDREW BENNETT and HARPREET DHILLON

Diamond material produced via microwave plasma chemical vapor deposition (CVD) is enabling a multitude of optical applications due to its range of extreme properties. Transparency from the ultraviolet (UV) through the infrared (IR) wavelength range is complemented by the highest thermal conductivity of any bulk material, high laser damage threshold, low thermal expansion, and chemical inertness.

A new, low-absorption-grade, single-crystal diamond that enables Raman frequency shifting for high-power laser systems has been developed by Element Six to expand these capabilities. It allows engineers to access new wavelengths with excellent beam quality in the yellow part of the spectrum for medical use and mid-IR wavelengths for eye-safe applications.

Frequency shifting

There are two key methods of moving to longer wavelengths: optical parametric oscillators (OPOs) and Raman lasers. The OPO architecture has had a strong advantage for a number of years, as output wavelengths are easily tuned by small changes to the properties of the nonlinear optical crystal through changes in temperature or orientation.

Raman lasers on the other hand rely on stimulated scattering between an optical pump and scattering centers in the Raman laser medium, related to high-frequency atomic vibrations. As the resulting frequency shift is related to the energy of these atomic vibrations, or phonons, each crystal can only shift the frequency by specific amounts equivalent to multiples of the phonon energy. This limits the wavelengths that can be accessed using Raman lasers to the particular source.

A distinctive feature of stimulated Raman scattering (SRS) is that momentum conservation is automatically taken care of by the scattered phonons, so that efficiency is largely independent of temperature and angle. This automatic phase-matching advantage is responsible for the ability of incoherent light to be converted into an output beam of very high quality. In addition, the gain profiles mean that over many round trips in the laser cavity, the gain in a Raman laser approaches the Gaussian shape that is fundamentally ideal for generating diffraction-limited laser beams.

For some time, the tuning advantage of OPOs has made them a more prevalent route to frequency shifting. However, both OPOs and the incumbent Raman-shifting crystals have struggled to handle high peak or average powers that might be seen in lasers used in materials processing applications, for example.

High-purity engineered diamond

Diamond has long been known to be an exceptional optical material, particularly at high powers. It is transparent at a wide range of wavelengths from the mid-UV (the band gap of diamond is 5.45 eV) to the microwave region of the spectrum, meaning it can be used in a wide range of lasers operating at diverse wavelengths.

Diamond also has the highest room-temperature thermal conductivity of any bulk material: two orders of magnitude higher than many optical engineering materials. It also has high fracture strength, allowing optics that must withstand stresses to be thinner, and high Young's modulus means that it retains its shape well, even under large loads. It also has a low coefficient of thermal expansion for stable operation in a variety of temperature environments.1,2

Historically, early applications relied on high-quality natural diamond samples, precluding their use in industrial applications due to high cost. But that was before the introduction of high-purity single-crystal diamond manufactured via CVD techniques.

With careful control of process parameters and feedstock quality, high-purity diamond with carefully controlled properties has been synthesized. Defect levels can be reduced and controlled to a few tens of parts per billion (ppb), and while many of the early optical products were polycrystalline in nature, single-crystal parts are now available in reasonable sizes—up to 8 × 8 mm and 2 mm thick—with bigger sizes under development.

Diamond for Raman lasers

With the development of ever-higher-quality grades of CVD diamond, interest in using diamond in Raman lasers has grown.3 Diamond Raman lasers make an excellent frequency-shifting solution, overcoming many of the limitations of current systems. First, diamond has a higher stimulated emission efficiency, or Raman gain coefficient, than any of its competing materials. Due to the stiff lattice and light carbon atoms, it has a high Debye temperature (the temperature of a crystal's highest normal mode of vibration), giving a larger frequency shift or higher spectral resolution than its competitors.

Of course, the excitation of lattice vibrations is effectively heating the material. Critically, for high-power laser systems there is a significant heat load that needs dissipating; here, diamond excels beyond other materials due to its exceptional thermal conductivity.

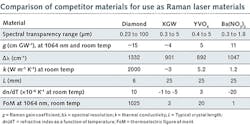

And when comparing CVD diamond to a range of standard Raman materials, diamond's figure of merit—the ratio of Raman gain coefficient to the pump laser attenuation coefficient—is around two orders of magnitude higher than the competitor materials (see table).

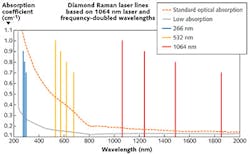

In addition to superior material properties, diamond's very high transparency means it can be used for a range of wavelengths that other materials cannot compete with (see Fig. 1).

Successful diamond Raman lasers have now been reported, working at a range of different wavelengths, operating at high powers and high beam qualities, for both continuous-wave and pulsed systems, and with efficiencies > 90%. The three case studies that follow demonstrate the range of performance that can be achieved.

Case 1: High power and high beam quality

Raman conversion for high-power laser beams is intrinsically challenging. The transfer of energy to phonons in a Raman laser directly heats the crystal, and since high intensities are required to drive the third-order nonlinear gain, there can be very high local heating. In most materials, this would create severe challenges with thermal lensing.

In diamond, the high Raman gain coefficient means that the threshold for lasing is low compared to competitor materials, allowing lower beam intensities; the high thermal conductivity and moderate thermal expansion coefficient keep thermal lensing to a minimum.

Exploiting these exceptional thermal properties, Richard Mildren's group at Macquarie University (Sydney, Australia), one of the leading groups working on diamond Raman lasers, has demonstrated stable diamond Raman lasers operating at greater than 100 W—already an order of magnitude higher than possible with alternative Raman laser materials.4

In addition, Mildren's team has also reported significant improvements in brightness using this system. A combination of the automatic phase matching typical for all Raman lasers, and the greatly reduced thermal lensing of diamond Raman lasers means the systems have allowed them to produce diffraction-limited beams.

Finally, the group has also reported beam cleanup of multimode or aberrated beams under some conditions. For example, in a system based on a Q-switched neodymium laser operating at 35 kHz and 50 W of average power, the beam divergence of approximately four times the diffraction limit was converted to the second Stokes wavelength at around 1.5 µm, with a diffraction-limited beam quality (m2 < 1.1).

Overall, this conversion provided a 70% increase in brightness despite the intrinsic loss of the Raman shifting process. This combination of high brightness and efficient conversion could lead to applications from improved materials machining throughputs to long-range, eye-safe laser systems for rangefinding.

Case 2: Tunable solid-state lasers

There are very few tunable solid-state lasers available, and those that exist can be large and complex systems. Tunable Raman lasers developed in the past are limited to low output powers due to the poor thermal conductivity of the Raman material. But diamond removes this barrier, leading to multiwatt output powers at wavelengths difficult to achieve with conventional lasers.

The University of Strathclyde (Glasgow, Scotland), which has used diamond for a range of optical applications for a number of years, has recently combined the Raman laser's intrinsic frequency-shifting capability with both a tunable semiconductor disk laser (SDL) and frequency-doubling crystal to create a single solid-state laser system capable of producing a range of wavelengths.

The groups of Dawson, Kemp, and Hastie have between them worked on surface functionalization of diamond intra-cavity cooling for various disk laser systems (semiconductor and solid-state) and Raman lasers. In doing so, they have achieved > 4 W at a range of wavelengths in the IR and > 1 W in the visible-notably in the orange portion of the spectrum.5 The indium gallium arsenide (InGaAs)-based quantum well SDL operates between 960 and 1080 nm, and was shifted to between 1209 and 1256 nm using a diamond Raman laser. The beam quality remained good, with m2 < 1.4, and decreased further when higher power output was achieved.

Inclusion within the Raman laser of a lithium triborate frequency-doubling crystal produced a range of wavelengths from 604 to 620 nm. This research has led to the development of a simple and stable solid-state laser concept capable of accessing a range of wavelengths for applications such as sensing or spectroscopy, not possible with current laser systems.Case 3: Monolithic diamond Raman lasers

The University of Strathclyde is also developing a monolithic diamond Raman laser that converts green to yellow light. The high-power, high-brightness, high-efficiency yellow laser light expands the range of application possibilities and demonstrates the capability to retrofit diamond components into existing laser systems (see Fig. 2).6

Future opportunities

A range of different diamond laser solutions have been demonstrated in the last five years, including continuous wave, Q-switched, and ultrafast temporal domain lasers with output wavelengths spanning the deep-UV to the mid-IR region. The limits of diamond Raman lasers with regard to peak and average power have not yet been reached, and kilowatt-class lasers are now being investigated. With continued research into larger and higher-purity diamond components, interest in the possible uses for diamond Raman lasers will continue to grow.

REFERENCES

1. R. S. Balmer et al., J. Phys. Condens. Matter, 21, 36, 364221 (2009).

2. J. M. Dodson et al., "Single crystal and poly crystalline CVD diamond for demanding optical applications," Window and Dome Technologies and Materials XII conference, paper 8016-20, Orlando, FL (Apr. 2011).

3. I. Friel et al., "Development of high quality single crystal diamond for novel laser applications," Proc. SPIE, 7838, 783819 (2010).

4. R. P. Mildren et al., Optics & Photonics News, 44–49, (Sept. 2014).

5. D. C. Parrotta et al., IEEE J. Select. Topics Quantum Electron., 19, 4, 1400108 (2013).

6. S. Reilly et al., Opt. Lett., 40, 6, 930–933 (2015).

Andrew Bennett is principal research scientist and Harpreet Dhillon is senior research scientist at Element Six, Kings Ride Park, Ascot, Berkshire, SL5 8BP England; e-mail: [email protected]; www.e6.com.