Spectral Imaging: Compact, high-performance hyperspectral imaging systems

LEAH ZIPH-SCHATZBERG and KEITH NAKANISHI

In demanding applications, miniaturized sensors are required to provide high performance, uncompromised by their small size, weight, and power (SWaP). High-performance characteristics include coherent, simultaneous capture of all spectral information corresponding to each spatial pixel, high optical throughput for maximal sensitivity, and low spectral/spatial distortion.

All-reflective Offner imaging spectrographs deliver these high-performance characteristics, so Corning has focused its sensor development efforts on Offner configuration sensors. Affixed with an entrance slit, an Offner spectrograph captures one spatial line of scene imagery, disperses each pixel of the line into its spectral components in the direction perpendicular to the slit, and focuses the light onto a 2D focal plane array (FPA). To acquire a 2D scene, the line of spectrograph imaging is scanned in a push-broom fashion with synchronous framing of the FPA. This can be achieved with constant forward motion of an aircraft, by mechanical rotation or translation of the sensor, or through the use of a scanning input mirror.

The design and performance of Offner-configuration hyperspectral imaging (HSI) sensors can be further improved by embedding the spectrograph into a solid block of optical material. The high index of the optical block reduces the light ray paths relative to an air- or vacuum-spaced sensor, resulting in smaller size and lower weight while retaining the low aberration features inherent to the Offner configuration.

Manufacture of such a monolithic spectrograph requires unique capabilities. The optical surfaces-including the grating-must be polished directly into the monolith. Complete spectral fidelity and spatial resolution performance optimization may require that the mirrors and/or grating be configured with non-spherical surfaces. Radiometric optimization may require a grating that is single- or dual-blazed, phase-stepped, or has aberration-correcting periods.

High-reflection coatings are applied to the optical surfaces, which are then fully encapsulated for environmental immunity. Other processes coat non-optical surfaces with an absorber to eliminate stray light. Manufacturing methods allow the incorporation of mounting features directly into the monolith. The resulting spectrograph is mechanically, environmentally, and thermally robust, and is auto-aligned, requiring no initial alignment or realignment.

One visible-near-infrared (visNIR) monolithic spectrograph measures only 2.9 × 1.9 × 1.5 in., with the complete sensor (with array detector and foreoptic) being only 6 × 2.5 × 2.4 in. and 0.45 kg. This monolithic visNIR HSI sensor with 16 mm foreoptics is shown in Fig. 1a. A single USB connector controls and powers the sensor using proprietary software, which enables data acquisition, sensor and scanner coordination, data analysis, and data export. Figures 1b and 1c show the sensor in two scanning configurations: a laboratory configuration and an organic scanner configuration for ground-portable operation.

Counter-IED missions

The monolithic HSI sensor designs have been field-proven. The NAREOS4 system was a joint collaboration between NovaSol (Honolulu, HI; now part of Corning) and the Naval Air Systems Command (NAVAIR) Special Surveillance Programs at Patuxent River, MD. The purpose of this program was to design, build, and deploy a small multi-mission advanced sensor system capable of real-time processing and display of target-enhanced EO imagery.

The system was a compact package capable of being hosted onboard a Tiger Shark unmanned aerial vehicle (UAV) to assist in counter-IED missions. The typical concept of operation (CONOPS) had NAREOS fly over an area of interest and transmit real-time detection chips to the ground control station for assessment.

The NAREOS system comprised the NovaSol (Corning) visNIR microHSI sensor, the Mission-adaptable Narrowband Tunable Imaging Spectrometer (MANTIS-5) multispectral imaging (MSI) sensor, an inertial navigation system (INS), a real-time processor, and other ancillary network connectivity components. The system was capable of simultaneously processing both sensors' data streams, producing detection results, and down-linking a waterfall image and detection regions of interest to the ground station for evaluation.

The NAREOS UAV was augmented with an EO/IR turret for demonstration during the test flight. The Corning HyView user interface was enhanced to allow the payload specialist to select a detection chip and send it to a centralized control and display system for evaluation and further exploitation. The instructions for the demo were that, upon receipt of the NAREOS detection, the system would command the EO/IR system to slew to the detection coordinates to visually confirm the target.

Studying coastal waters

As part of the NASA Research Opportunities for Space and Earth Sciences (ROSES) program, the Corning (previously NovaSol) Selectable Hyperspectral Airborne Remote-sensing Kit (SHARK7) was flown on the unmanned Vision-II helicopter (see Fig. 2). The goal of the May 2013 data collection was to obtain high-resolution visNIR HSI data of sea grasses and coral reefs in the shallow coastal waters of the Florida Keys. The configuration of the SHARK system was a visNIR microHSI with 4001000 nm range and 120 bands; an inertial navigation system; and data acquisition electronics.The Vision-II helicopter UAV does not have the range or endurance of fixed-wing UAVs, but as a rotary-wing aircraft it has the ability to take off and land in a limited area without a runway, enabling the UAV to deploy from locales in close proximity to experiment areas. Another advantage is its slow forward speed, allowing for long sensor integration times—a key feature when imaging underwater targets.

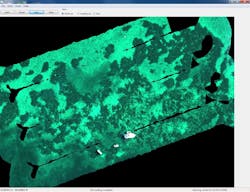

Analysis of the NASA ROSES Florida Reef and Seagrass Survey Project data is still underway, primarily at the University of South Florida5 and also at the Florida Fish and Wildlife Conservation Commission.6 Results indicate the ability of HSI sensing to effectively differentiate and characterize coral, seagrass, and mixed sea-bottoms. Sample imagery from the flights is shown in Fig. 3.Crop analysis

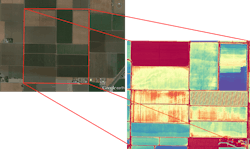

The monolithic HSI sensor design has demonstrated performance in precision agriculture, which uses HSI sensing to monitor a wide range of variables that affect crops, including moisture content, photosynthetic activity, and weed or pest infestations. Farmers can then manage their crops more efficiently and sustainably, improving harvest yields while reducing the negative environmental impact of over-application of chemicals and water.

Vegetation indices provide field metrics and are combinations of surface reflectance at two or more wavelengths designed to highlight a particular property of vegetation. They are derived using the reflectance properties of the vegetation. More than 150 vegetation indices have been published, with each index designed to accentuate a particular crop property.

Efficient water usage is becoming extremely important, especially in the drought-ridden areas of California. The water band index signals changes in the canopy water status—a higher number indicating more water content in the vegetation. Additional agricultural applications include crop stress analysis, productivity prediction, and fire hazard alert.

The Red Edge Normalized Difference Vegetation Index (ReNDVI) is a modification of the broadband NDVI. It is intended for use with very high spectral resolution reflectance data, such as data from HSI sensors. The ReNDVI capitalizes on the sensitivity of the vegetation red edge to small changes in canopy foliage content, gap fraction, and senescence. Applications include precision agriculture, forest monitoring, and vegetation stress detection. A sample ReNDVI map generated from data acquired with a Corning visNIR microHSI sensor during the 2014 growing season is shown in Fig. 4.ACKNOWLEDGEMENT

visNIR microHSI is a trademark of Corning.

REFERENCES

1. C. P. Warren et al., "Miniaturization of a VNIR hyperspectral imager," Proc. SPIE, 6302, Imaging Spectrometry XI, 63020N (Sept. 1, 2006); doi:10.1117/12.680881.

2. C. P. Warren et al., "Miniaturization of a SWIR hyperspectral imager," Proc. SPIE, 8020, Airborne Intelligence, Surveillance, Reconnaissance (ISR) Systems and Applications VIII, 802002 (May 13, 2011); doi: 10.1117/12.883325.

3. C. P. Warren et al., Opt. Eng., 51, 11 (2012).

4. K. Nakanishi et al., "NAREOS system and UAV flight," Military Sensing Symposia (MSS) Specialty Groups on Passive Sensors, Battlefield Survivability & Discrimination, Detectors & Materials (2012).

5. D. English et al., "Hyperspectral remote sensing of shallow coastal waters in the Florida Keys using Unmanned Aircraft Systems (UAS): Initial results from atmospheric correction and glint reduction," Ocean Optics (2014).

6. P. Carlson, "Seagrass biomass, productivity, and hyperspectral remote sensing in the Florida Keys," American Geophysical Union (2013).

7. K. Nakanishi, "Selectable hyperspectral airborne remote-sensing kit (SHARK) on the Vision-II Turbine Rotorcraft UAV over the Florida Keys," American Geophysical Union (2013).

Leah Ziph-Schatzberg is program manager at Corning Specialty Materials, Keene, NH, and Keith Nakanishi is senior systems engineering manager at Corning Advanced Optics, Honolulu, HI; e-mail: [email protected]; www.corning.com.