DAVID PUREUR

Since the mid-2000s, fiber laser technology has demonstrated its usefulness for material processing applications. But the advantages of fiber laser design—including mechanical stability against temperature and vibrations, beam quality, and the ability to generate high power in the infrared (IR) range with good wall-plug efficiency—also make fiber lasers attractive for new applications. For instance, they offer plug-and-play operation with more functionality and power in the visible spectrum range for such biotechnology and scientific instrumentation as super-resolution microscopy, DNA sequencing, and sensing. In fact, many instruments today require high-power continuous-wave (CW) lasers (typically watt-level) at wavelengths such as 532, 561, 592, 642, and 660 nm, as the following few examples illustrate.

Bioinstrumentation

Light diffraction and its limiting influence on spatial resolution has been an obstacle in far-field optical microscopy, a workhorse for cell biology. New techniques such as stimulated emission depletion (STED), ground state depletion (GSD), and reversible saturable optically linear fluorescence transition (RESOLFT) address the limitation. In STED microscopy, probing of the fluorophore attached to the cell is achieved by restricting the space in which fluorescence occurs. This restriction is achieved with a STED laser (superimposed on the low-power excitation source) that depletes the fluorescent molecules in the outer part of the excitation area through stimulated emission. In practice, this STED beam is shaped in a doughnut-like pattern, featuring a central zero-intensity point in the focal plane. The spatial resolution of this technique is inversely proportional to the CW STED beam intensity, and watt-level lasers working in CW at 592, 660, or 775 nm are typically required.

Laser-based, sub-diffraction techniques are also used for high-speed fluorescence microscopy and in biological experiments. As many of these techniques rely on large-field fluorescence imaging, such as single-molecule localization (SML),1 the background signal often can be an issue. To mitigate this, some microscopes use massive parallel localization of molecules achieved through wide-field imaging and higher power lasers working at 561, 640, or 750 nm.

Another dynamic area of bioinstrumentation is DNA sequencing. Most commercially available sequencers are based on laser-excited fluorescence, as each of the four nucleotides (A, C, G, T) that compose DNA has a unique, detectible fluorescence profile. Today, these instruments are characterized by higher throughput and lower cost. Reduced cost and increasing the speed of genome analysis requires massively parallel processing of DNA strands. As with many sub-diffraction microscopes, the procedure requires a wide-field illumination and higher laser power. For applications wherein single strands of DNA are sequenced and the fluorescence signal is weak, laser power level is also critical.2

Both the new generation of DNA sequencing instruments and the super-resolution microscopes mentioned need high power lasers mainly in the green, orange, and red portions of the visible spectrum. Generating watt-level power in the green range is relatively straightforward with standard solid-state technology. This is not the case for generating the same power in the yellow, orange, and red, however, where fiber lasers are often the only available technical solutions. These applications require very stable power over time despite environmental fluctuations as well as near-perfect beam quality (M2 < 1.1)—characteristics that contributed to the success of fiber lasers for materials processing.

Ophthalmology

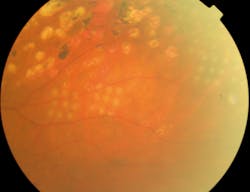

Currently, lasers used in ophthalmology for the treatment of the retina mainly emit at 532 nm. A power of 1–2 W is needed to activate the photocoagulation process in the treatment of retinal detachment. This wavelength fits the absorption bands of oxyhemoglobin and melanin, and for many years has been the only wavelength accessible with solid-state lasers. Yellow (577 nm) light also fits the relevant absorption bands, however, and is not absorbed by xanthophyll pigment contained within the retinal sub-layer (see Fig. 1). This results in a smaller and thinner heat-affected area compared to a treatment at 532 nm. And with the development of new laser technologies, yellow becomes accessible. Fiber laser technology is a candidate to generate several watts at this particular wavelength. Besides its almost-perfect beam quality, fiber delivery and the small heat load of the optical head are key advantages.Achieving yellow-orange-red

Watt-level laser generation in the yellow-red range (typically 560–670 nm) with a good beam quality is challenging for most solid-state technologies.With a bulk diode-pumped solid-state (DPSS) laser, because the gain medium is a crystal, the emitted wavelength in the red range (for example) is limited to 660 and 671 nm (the frequency-converted wavelength through second-harmonic generation, respectively, of the Nd:YAG 1320 nm transition and the Nd:YVO4 1342 nm transition), with some limitations in terms of accessible optical power and efficiency.

Optically pumped semiconductor laser (OPSL) technology, based on an indium gallium arsenide (InGaAs) gain chip, provides more wavelength flexibility and the laser can be set anywhere between 920 and 1154 nm, yielding frequency-doubled and -tripled output between 355 and 577 nm. Nevertheless, OPSL has strong limitations in reaching orange wavelengths around 590 nm and wavelengths above 639 nm.

The most efficient solution for yellow-orange and red wavelengths is a fiber laser. With a doped silica matrix as gain media, these lasers can emit a wide range of wavelengths. Quantel's laboratory has demonstrated a CW laser delivering watts from 1060 to 1180 nm in ytterbium (Yb)-doped fibers (longitudinally multimode lasers) and from 1534 to 1590 nm in erbium (Er)-doped fibers. Emitted wavelengths can be frequency-shifted to even higher wavelengths using Raman fiber converters—though at the expense of much more complex architecture, lower efficiency, and degraded noise performance.

Emitting from a CW IR laser at a particular wavelength, the beam is sent to a quasi-phase-matched crystal (of ferroelectric, periodically poled materials like lithium niobate [LN] potassium titanyl phosphate [KTP], lithium tantalate [LT], etc.) to generate a second-harmonic beam. By adjusting the IR laser as well as the crystal pitch, a broad range of wavelengths from 530 to 590 nm can be covered in a single-pass, second-harmonic-generation scheme. This means that no bulky cavity is needed for the second-harmonic beam (a bulky cavity can negatively influence beam characteristics, such as M2, pointing stability, and power stability). Such architecture works both with longitudinally multimode lasers and single-frequency lasers, and has an efficiency ranging from 10 to 40%, depending on power level and crystal parameters, among others. For example, starting with an 1154 nm laser, one can get up to 3 W at 577 nm with an efficiency of around 30%.A red laser beam can be generated similarly using sum frequency generation (SFG) of two IR fiber lasers. As depicted in Fig. 2, by spatially multiplexing a fiber laser emitting at 1560 nm with a second laser emitting at 1064 nm and then sending both IR beams through a periodically poled crystal with a pitch adapted for SFG, one can generate wattage at 633 nm. Using slightly different IR wavelengths, up to 10 W at 642 nm with a nearly perfect beam quality and a polarization extinction ratio of 20 dB (see Fig. 3) has been demonstrated in Quantel's lab. The IR laser can be a simple fiber cavity with two Bragg gratings or a complex master oscillator power fiber amplifier (MOPFA) architecture with single-frequency properties. In all these laser designs, one of the major difficulties is implementing an IR cavity design that works at extreme wavelengths, at the edge of the spectral profile emission of Yb or Er dopants in fibers.

Intensity noise of the visible laser is a critical parameter for bioinstrumentation. At 642 nm, Quantel measured a relative intensity noise (integrated from DC to 100 KHz) below 1% for a power ranging from 0.2 to 2.0 W (longitudinally multimode laser). Aging experiments in the yellow-red range conducted over thousands of hours did not show any crystal degradation over time, power, or temperature.

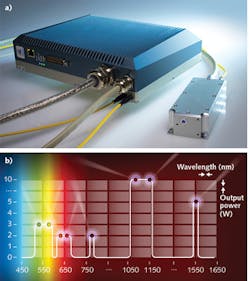

Quantel released the ELBA laser platform based on these fiber architectures: It delivers 2 W in the red range and 3 W in the yellow range (see Fig. 4). The ELBA uses a small frequency-conversion module attached to the IR box with a 3 m fiber delivery. The generated heat of the module is 10-15 W, which makes this fiber-based solution ideal for any application that requires compactness, watt-level power, high stability vs. temperature and vibration, and low heat load.

As there is an evolution in some life sciences applications towards wide-field illumination and massive parallelism to collect more data, higher power laser solutions are needed. Today's compact plug-and-play fiber lasers generate about 1 W at specific visible wavelengths and correspond to the absorption bands of such targeted species as fluorophores attached to cells or human tissues.

REFERENCES

1. B. Huang et al., Annu. Rev. Biochem., 78, 993–1016 (2009).

2. V. Pfeufer and M. Schultze, "Laser fluorescence powers sequencing advances," BioOptics World, 8, 1, 24–27 (Jan/Feb. 2015).

David Pureur, Ph.D., is fiber laser business unit manager at Quantel Laser, Les Ulis, France; e-mail: [email protected];www.quantel-laser.com.