Photonics Applied: Materials Processing: Nanosecond pulsed fiber lasers advance in metal cutting

The success of fiber lasers with nanosecond pulse widths for marking applications is well known. For the past 10 years, they have become the dominant laser source for metallic marking and, as their average powers continue to increase, their use for engraving applications is growing. Having typically less than a few millijoules in pulse energy with peak powers around 10 kW and average powers now up to 100 W, they pack an impressive punch.

Pulsed fiber lasers from SPI are based on a master oscillator power amplifier (MOPA) design using a semiconductor seed laser in combination with optical fiber amplifiers, enabling significant control over pulse characteristics compared to conventional Q-switched designs.

The pulses generated by these nanosecond fiber lasers have a characteristically rapid rise time that leads to more effective beam coupling to the target material compared to conventional Q-switched pulses with a nominal Gaussian energy distribution. With a 1.06 μm operating wavelength, nanosecond fiber lasers with scanner-based beam-delivery systems can offer very fast materials processing speeds.

Although typically applied to marking applications, the versatility and control of today's nanosecond pulsed fiber lasers enables them to compete in a variety of micromachining applications, including engraving, ablation, scribing, texturing, and micro cutting. With a broad range of repetition rates from 1 kHz to 1 MHz and variable pulse-width control from 3 to 500 ns, these nanosecond-realm pulsed fiber lasers can operate in continuous-wave (CW) as well as modulated quasi-CW mode.

Metal foils

To achieve full penetration in thin-foil type metals, the cutting speed is the controlling parameter in what can be a simple single-pass process for nanosecond pulsed fiber lasers. And because the process is typically scanner-based, process gas is not required.

Metal foil cutting with scanner-beam delivery is accomplished through ablation and melt ejection, resulting in a burr-free cut with minimal heat-affected zone (HAZ). For example, copper and aluminum battery foils can be complex materials, typically having a 20–40 μm metallic core sandwiched between several proprietary layers that result in a total material thickness of around 100 μm (see Fig. 1). These battery foils can be cut with a 70–100 W pulsed fiber laser at linear cutting speeds of greater than 1 m/s, making laser cutting a better option than mechanical cutting techniques that suffer from tool wear, periodic maintenance, and a general lack of flexibility.

Cut quality is extremely important in this application, where minimal burr and no damage to the thin-film coating are essential. Cut quality can be controlled by optimization of the pulse and process parameters, but it has been found that for some materials, a two-pass process can result in edge-quality improvements.

Thick metals

For cutting thick metal materials up to 0.5 mm, multiple beam passes along a coincident path are often required to achieve full penetration through the material. However, there are limitations to this technique in that optimization of the beam parameters at the surface of the material degrades as the depth and aspect ratio of the groove are increased through multiple passes, causing beam attenuation and reducing materials processing efficiency. The process is effectively self-limiting; adjustment of the spot size and moving the focal position within the material can improve the situation, but only marginally.

As when cutting with CW lasers, the beam quality can have an impact. However, with pulsed fiber lasers, beam quality is less about m2 and more about the pulse energy and peak power that can be achieved.

In a direct comparison between three lasers of different beam qualities (all operating at 20 W through the same optical arrangement), it was found that the laser with the highest beam quality of M2 < 1.3 did not achieve the best cutting result because the lower pulse energy and lower peak power of the high-quality beam was not adequately compensated for by the smaller spot size. The laser with M2 < 2 trailed a poor third because although it had higher pulse energy and peak power, the large spot size generated a significantly lower energy density on the material. Finally, the laser with M2 < 1.6 gave the best result in that it had the optimal combination of pulse energy and power in a moderately sized spot.

To adequately cut thicker materials, novel cutting strategies need to be adopted to effectively widen the kerf and allow more material to be removed. Although this is achieved by increasing the laser spot size, this method has the adverse effect of reducing the incident energy density and hence material removal efficiency.

A more effective method, particularly suited to x-y table-based systems, is to offset the cut line between passes to some value on the order of the focal spot diameter, effectively doubling the cut width. Care needs to be taken in programming to ensure that the dimensions of the finished part are acceptable and as the thickness of the material cut increases, a slight taper on the cut edge is created.

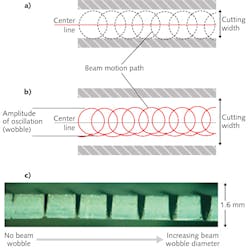

With scanner-based beam delivery, the "wobble" feature of standard commercially available laser marking software (originally developed to widen the marking line to make it more visible) can be used to good effect (see Fig. 2). Essentially, this wobble feature oscillates the beam in a circular motion at a user-definable diameter and frequency along the cut path trajectory.Using this wobble feature, the beam is effectively spiraling at a predetermined amplitude along the cutting line. Careful control of the wobble width, wobble frequency, and cut line speed is required to optimize the pulse overlap to maximize material removal.

Thicker and reflective metals

To cut metals > 0.5 mm thick, more complex multipass machining strategies can be used where the parameters can be optimized for each pass. These techniques can be used on all metallic materials, but cutting speeds and achievable thickness can vary. For example, a 100 W pulsed fiber laser can achieve a 0.9 m/min cutting speed in 1-mm-thick aluminum, while the cutting speed drops to just 0.2 m/min in 1-mm-thick silver.

Laser cutting speeds are impacted by material reflectivity, but nanosecond pulsed fiber lasers can process highly reflective materials at relatively low average power levels compared to CW fiber lasers. This is possible because the peak power of these nanosecond pulsed fiber lasers can be more than 100X greater than that of their CW counterparts, easily overcoming the material thresholds of thicker metals.

For conventional CW laser cutting of reflective materials, average powers > 200 W (for 1 μm sources) are generally required to achieve stable absorption and adequate cutting performance, meaning that pulsed fiber lasers with significantly lower average power can cut materials that would require significantly higher average CW power levels.

With and without assist

Conventional cutting requires a cutting head where the laser beam is focused onto the workpiece and a coaxial cutting assist gas is applied through a nozzle. The laser beam melts the material and the assist gas blows away the melt to generate the cutting action.

Although metal cutting using scanner-based techniques is typically limited to material thicknesses < 1 mm and for small parts that fall within the working field of the scan lenses (around 100 × 100 mm), thicker sections can be processed with pulsed fiber lasers but may require periodic adjustment of the focal position to maintain energy density. Alternatively, CW lasers are not suited to scanner-based cutting, as they do not generate sufficient vaporization to effect material melt ejection and hence are generally used with fixed optics and an assist gas.

Beyond this obvious advantage of not requiring consumables (assist gases), scanner-based nanosecond pulsed fiber lasers for micro-cutting applications have a relatively low capital cost. While CW fiber and carbon-dioxide (CO2) lasers with a fixed optic, cutting head, and assist gas are typically > $100,000 machine tools, a scanner-based 20 W pulsed fiber marking system applied to metallic cutting-albeit of thin sections and with limited part size-will set you back a mere $20,000.

Plus, there is the added benefit that nanosecond pulsed lasers can mark, engrave, and texture, as well as cut and weld. This versatility is well exploited in the jewelry industry, where nanosecond pulsed fiber lasers are the norm for processing (both cutting and engraving) fine filigree-based silver and gold items, giving designers and manufacturers extreme flexibility (see Fig. 3).Many pulsed fiber lasers are in 24/7 manufacturing environments where the reliability of these laser sources is equating to strong sales growth in numerous application areas. The ability to change pulse duration with fiber lasers offers an additional route to process optimization by affecting material removal rates according to material type.

Pulsed fiber lasers can also be used in conjunction with a standard cutting head and nozzle with assist gas just like conventional CW fiber lasers. Even a 50 W nanosecond pulsed fiber laser can cut silver, brass, and copper that would normally require CW fiber laser power levels > 200 W (see Fig. 4).When cutting with an assist gas, fiber lasers can be used in either pulsed, CW, or quasi-CW mode, depending on the application. In pulsed mode, the high-peak-power beam is easily coupled into the material, enabling cutting of highly reflective materials at low average powers, although sometimes, the associated cutting speeds can be low. In CW mode, the intensity is limited to the average power of the laser and so cannot be used on reflective materials, as the coupling threshold is not achieved. The use of long nanosecond pulses (> 200 ns) at high repetition rates (> 200 kHz) generates a modulated quasi-CW pulse stream with peak powers > 200 W that are particularly well suited to this technique, and able to cut a wide range of materials up to 1 mm thick with < 100 W average power lasers.

More than metals

It should be noted that the use of nanosecond pulsed fiber lasers for cutting is not restricted to just metals. These lasers can be used effectively on a wide variety of non-metallic materials that exhibit at least some level of absorption of their nominal 1 μm wavelength. Other materials that can be cut include silicon, carbon-fiber reinforced plastic (CFRP), ceramics, rubber, some plastics and polymers, and even multilayer materials common in the electronics industry.

Jack Gabzdyl | Industry Manager – Electronics, TRUMPF Laser UK Ltd

Dr. Jack Gabzdyl is Industry Manager – Electronics at TRUMPF Laser UK Ltd (Southampton, England) and has more than 30 years of laser materials processing experience. He obtained his PhD in laser processing from Imperial College London in 1989. He has since had a number of technical and marketing positions at BOC Gases, Advanced Laser Solutions, and TWI before joining TRUMPF (formerly SPI Lasers) in 2007.