High-index immersion fluid enables 1.17 NA objective with 12 mm working distance

Because of its high refractive index of about 1.77, the sapphire-based aplanatic numerical-aperture-increasing lens (aNAIL) can produce a higher resolution than ordinary optics when used for imaging in microscopes. The aNAIL can enable super-resolution 3D imaging via depth-scanning of specimens. An immersion lens, the aNAIL requires a suitable index-matching fluid for operation. However, conventional index-matching fluids with such a high refractive index have high absorbance and scattering—which prevent depth scanning and, thus, 3D imaging.

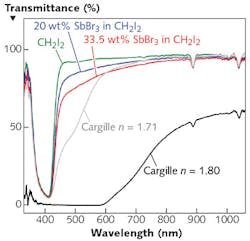

To eliminate this problem, researchers from the Max Planck Institute for Dynamics and Self-Organization (Göttingen, Germany), IIT Guwahati (Assam, India), North Carolina State University (Raleigh, NC), and the Friedrich-Alexander-Universität Erlangen-Nürnberg (Erlangen, Germany) have created an index-matching fluid made of antimony tribromide (SbBr3) salt dissolved in liquid diiodomethane (CH2I2), producing a refractive index that is tunable from 1.74 to 1.873 by varying the proportion of CH2I2 (see figure, which also includes two conventional Cargille index-matching fluids for comparison). The fluid has high transmission and low scattering for λ < 350 nm and λ ≥ 450 nm. Along with the new fluid, the researchers developed a sapphire-based aNAIL objective that has a high numerical aperture (NA) of 1.17 and a very large working distance of 12 mm. They see other uses for the fluid also, including the development of high-index adaptive liquid lenses. Reference: J. M. Laskar et al., arXiv:1512.08208v1 [physics.optics] (Dec. 27, 2015).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.