Optical Materials: Overcoming the challenges of coating plastic optics

Once dismissed by serious optical engineers, plastic optics (also known as polymer optics) have come into their own in the last 10-20 years. The introduction of advanced optical polymers and improvements in fabrication techniques now allow designers to replace even high-end glass optical components with plastic at a fraction of the weight or price, facilitating use in medical, industrial, and defense and security applications (see Fig. 1). Advances in optical coating technology for plastics have been key to this transition, enabling the delivery of comparable optical performance and durability despite the use of a very different class of substrate material.

The deposition of optical coatings on plastic or polymer substrates brings several challenges. Plastic optics cannot withstand the typical 250°C coating temperatures used for glass, nor the extended exposure required to apply hundreds of optical layers for complex spectral profiles. Optical coatings on plastics are also more prone to delamination, peeling, and flaking if not properly applied—particularly when subjected to harsh environmental conditions. This can place optical and environmental performance at odds, as an increase in the number of layers to achieve the desired spectral profile can increase stress between the substrate and coating, particularly during temperature cycling.

These competing demands have forced coating providers to revamp their processes from start to finish, developing specialized cleaning, handling, design, and coating methods—often for each plastic type. As a result of this investment, optical coatings on plastic from experienced vendors are now capable of delivering similar optical performance as available on glass. From antireflection (AR), mirror, and indium tin oxide (ITO) coatings to filters, beamsplitters, and hot mirrors, coated plastic and polymer optics now regularly pass the most stringent MIL-SPEC and ISO testing schedules.

Cooling down deposition

The relatively low melting point of most plastics requires the use of low-temperature deposition processes such as plasma ion-assisted deposition (plasma-IAD) or plasma-enhanced chemical vapor deposition (PECVD). Deposition temperatures as low as 40°-50°C are not uncommon to prevent deformation or warping of the substrate, particularly for a softer material like acrylic. Plasma parameters are adjusted to fine-tune optical performance, as well as to modify surface properties and adjust coating stresses that can impact environmental performance.1

Even without active heating of the deposition chamber, there is a certain amount of inherent heat in the deposition process itself, requiring careful attention to coating rates to prevent damage. The throw distance in the chamber can help to control heat, as does the use of different material—some of the high-index layers are formulated using rare earths.

Ensuring adhesion

Adhesion of optical coatings to plastics or polymers is not as strong as to glass. When compounded with differences in thermal expansion coefficients and thickness variations in the optic itself, it can limit the number of layers that can be deposited without compromising environmental performance. Pretreatment using low-pressure plasmas of argon (Ar), helium (He), or nitrogen (N2) has been shown to improve coating adhesion, stress compensation, and mechanical durability. Not only does this process serve to clean and micro-etch the surface in preparation for coating, but it can also offer crosslinking and surface-chemical functionalization.2

Extensive pretreatment is not always necessary, however. Binder layers are an alternative to improve adhesion of metal coatings such as gold, while some advanced cyclic olefin copolymers like Zeonex and TOPAS provide excellent adhesion properties.

Cleaning and handling plastics

Creating a good-quality coated optic from a plastic substrate depends heavily on proper cleaning and handling of the parts prior to deposition. Many polymer materials scratch very easily when compared to glass and without proper cleaning, adhesion will be compromised.

Components like lenses, prisms, and windows are typically cleaned ultrasonically using material-specific chemicals and surfactants, followed by a hot rinse in deionized water and a hot air-dry to avoid damage. Hand cleaning may also be used, and each coating vendor should draw on their experience to select the best detergent solution to correct specific cleaning or adhesion issues. Sheet materials require their own unique handling methods to avoid damage and ensure cleanliness prior to coating, as well as specialized fixtures.

Not all plastics are created equal

Perhaps the most complex aspect of coating on plastic substrates is the tremendous variety and complexity of the materials available. Each has its own unique chemistry that interacts uniquely with the cleaning, preparation, and deposition processes employed, together defining the stress at the coating-substrate interface. This can constrain the optical performance of a coating required to pass specific environmental or MIL-SPEC testing. It also means that a coating that passes a given test on one type of plastic or polymer is not guaranteed to pass on another simply by using the same process, nor for every substrate shape or form.

The development of a deposition process and layer design must therefore treat the optical specifications, environmental requirements, substrate form, and choice of substrate material as linked parameters. A coating partner with extensive experience in coating a wide variety of plastic types and form factors can provide valuable advice early on in the design process to ensure the specification of manufacturable components with the best possible optical performance. Given the extended testing required for each component to prove environmental reliability prior to deployment, this consultation process with an experienced coating partner is a key risk mitigation step in the timeline of any major product or system development.

While deployment of coated plastic optics once meant choosing between optical performance and durability, advances in cleaning and deposition processes for polymer substrates have closed the gap. The majority of optical coatings available on glass can now be replicated on plastic, and with MIL-SPEC and ISO reliability. In the hands of an experienced coating provider, it is even possible to create a drop-in replacement for a glass component to reduce weight, cut cost, or allay safety issues associated with cracking and splintering in the field. With the capabilities and options in coated plastic optics increasing so significantly in the past decade, they're certainly worth another look.

REFERENCES

1. U. Schulz, P. Munzert, and N. Kaiser, Vak. Forsch. Prax., 17, S1, 26-29 (2005).

2. L. Martinu and D. Poitras, J. Vac. Sci. Technol. A, 18, 6, 2619-2645 (2000).

Coatings on plastic/polymer optics are now much more durable*

Operating environment tests:

24-hour humidity exposure

10-day humidity exposure

Temperature cycling: -62°C to +85°C

Temperature shock: +23°C/-57°C/+71°C/+23°C

Moderate abrasion

Adhesion

Salt solubility (not appropriate for metals)

Salt fog (not appropriate for metals)

Chemical exposure tests:

Insect repellent

Penetrating oil

Antifreeze

Carbon-removing compound

Lubricating oil

Rifle-bore cleaning compound

Vacuum-pump oil

*Note: Not all tests will be passed by all coatings on all substrates.

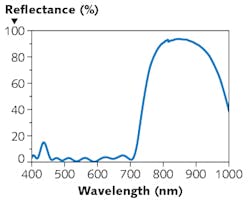

Case study: Hot mirrors for virtual-reality devices

Hot mirrors are used in virtual reality (VR) systems to reflect the infrared light used by eye or positional tracking systems while passing the visible light. These head-up display (HUD) optics need to be lightweight, and thus are coated on plastic. Optical requirements for VR vary, but can include 80-90% reflection of 800-830 nm light (see Fig. 2) or nonpolarizing beamsplitting of the laser light and visible light, both of which are now possible using coated plastic substrates.Paul Meier-Wang | President, AccuCoat

Paul Meier-Wang is president of AccuCoat (Rochester, NY).

Alan Parsons | Sales Manager, AccuCoat

Alan Parsons is sales manager at AccuCoat (Rochester, NY).

Cicely Rathmell | Vice President of Marketing, Wasatch Photonics

Cicely Rathmell, MSc, is vice president of marketing at Wasatch Photonics, and based in Dunedin, FL.