Laser-diode Electronics: How to protect your laser diode from electrically caused damage

AARON BROWNING

It is said that there are two types of researchers—those who have destroyed laser diodes and those who will. While this may be an exaggeration, it's certainly true that today's lab environments pose greater threats than ever to laser diodes. Furthermore, protecting laser diodes is commonly misunderstood and poorly implemented. Laser-diode protection is a priority because laser-diode damage is frustrating, time-consuming, and costly.

Fortunately, laser-diode damage is largely preventable by taking appropriate measures.

Physics of laser-diode damage

Laser diodes are extremely sensitive to electrostatic discharge, excessive current levels, and current spikes (transients). Symptoms of damage include reduced output power, threshold-current shift, beam-divergence changes, difficulty focusing, and ultimately failure to lase.

This article addresses how to prevent catastrophic facet damage, which causes the destruction of laser mirrors (because of heat), as well as latent damage from electrical transients related to handling/operating conditions, which cause premature failure under normal working conditions.

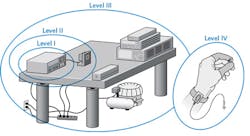

Each level of laser-diode protection is organized by damage mechanisms against which they protect (see table and Fig. 1). Tiers I - III can be controlled by laboratory setup. However, all four tiers of protection are critical in facilitating the maximum lifetime for laser diodes.

Level I: Instrumentation

Instrumentation used to control laser diodes should be designed with appropriate protection and AC-line transient suppression.

At minimum, instruments must: 1) include independent adjustable limit of drive current, 2) prevent reverse bias of diode junctions, 3) suppress electrical transient spikes from AC power lines, and 4) not produce its own current transients.

Current sources. Since semiconductor lasers are current devices, true current sources are recommended. Voltage sources carefully ramp voltage at turn-on, but current is not controlled. This allows current to change quickly for changing loads, putting laser diodes at risk.

Important design features when selecting proper current sources are shorting outputs to maintain output leads at identical potentials, slow start to protect against turn-on transients, independent drive current limits to prevent accidental current overdrive, over-voltage protection to prevent against voltage overdrive, and power-line transient suppression to protect from outside influences to devices. Figure 2 shows an example of a properly designed current source.Precise current sources, such as the ILX LDX-3200 series, are only one part of laser-diode protection, and individual instruments cannot protect against all conditions. This is why it is important to protect a device with a holistic approach to damage mechanisms.

Temperature controllers. Many critical laser-diode parameters such as wavelength, threshold current, efficiency, and lifetime are highly dependent on junction temperature. As an example, laser diodes may be rated for 100,000 hours running at 25°C, but would only run for 10,000 hours at 55°C.

This is why highly stable temperature control is a desirable aspect of any setup. Depending on requirements, heat-dissipation setup can be simple passive heat sinks, temperature controllers, or water-cooled systems. Temperature controllers coupled with heat sinks and thermoelectric modules are flexible options that accommodate most applications.

Temperature controllers, such as the ILX LDT-5900C series, allow users to precisely control temperature and speed at which temperature settles. Temperature controllers should have capability accepting wide ranges of sensors via adjusting constants, temperature/current limits, and adjustable PID constants. These functions allow control necessary to protect devices from premature failure.

Level II: System setup (mounting, cables, and grounding)

Choosing proper drivers is imperative for ensuring a protected laser diode. Instruments themselves cannot protect against transients that are radiated directly onto laser diodes or through system cabling. To protect against these threats, careful consideration of interconnections must be made during system setup.

"System setup" is defined to encompass diode mounts and cabling in addition to drivers and controllers. This includes other test equipment connected to the system. When constructing systems, the weakest link will determine relative strength of the system. This is especially true concerning radiated noise susceptibility.

For the purpose of setup, radiated electrical transients can be considered noise signals. This model includes three pieces: noise sources, coupling mechanisms, and receivers. Identifying and eliminating all elements of noise in laboratories is impractical.

Precautionary steps can be taken to prevent and eliminate most common transients.

Grounding. Grounding is a topic that is simple in concept, but complicated in practice. Most system elements are grounded for two reasons: 1) to determine voltage potential at which laser diodes operate with respect to earth ground and other equipment, and 2) to provide a return path for device current.

Mounting considerations. Laser-diode mounts, such as the ILX LDM-4980 series, perform the seemingly innocuous task of providing fixturing and heat-sinking. Certain considerations must be made to ensure safe environments for laser diodes.

Suppression of high-frequency noise is a significant consideration. Without proper grounding, mounts can act as antennas and can pick up radiated signals that can induce currents in case nodes of laser diodes. Proper shielding and grounding can correct this.

Packages isolated from earth ground allow greater freedom of connection and reduce the possibility of ground loops and interference. Packages that must be earth-grounded should have very low-inductance connections from the mount to ground. Grounding directly to power-line ground is the minimum requirement.

Cabling and shielding. Loose connections are seen as higher-impedance loads and can cause current overdrive. This is one reason why current limits and intermittent contact detection are critical protection features.

Twisted-pair cabling reduces low-frequency noise that otherwise inductively couples into signal conductors. However, without shielding, twisted-pair cabling causes additional capacitive noise. Shielding drains electrical fields through low-impedance connections to earth ground. This also prevents other electrical fields in labs from coupling onto cabling.

Level III: Lab environment

Whether laser diodes are damaged by power-line transients depends on several factors, including the magnitude of the transient, the temporal qualities of the transient, and the sensitivity of the laser diode.

The best practice for protecting against this damage mechanism is properly shielded cabling. Shielded cabling will act as a Faraday cage, significantly reducing transients.

Level IV: Handling and human contact

Proper handling is perhaps the most overlooked aspect of laser-diode protection. Careful storage, transport, and mounting of laser diodes are critical to ensuring optimum laser-diode lifetimes.

Laser diodes can be easily damaged or destroyed by electrostatic discharges (ESDs). It has been suggested that ESD is the single leading cause of premature laser-diode failure. Damage caused by ESD may not be apparent and may surface as a latent failure, which may be any of the mechanisms described in the "Physics of laser-diode damage" section.

When handling laser diodes, the following rules must be followed:

1. When handling unprotected devices, wear protective wrist straps designed to drain built-up electric charges safely to ground.

2. Place unprotected laser diodes on certified, static dissipative work surfaces.

3. When transporting, storing, or not working on laser diodes, completely enclose devices in conductive, shielded material. Short pins when not in use.

4. Keep all charge-generating materials at least 12 in. away from unprotected devices since devices can become charged inductively.

In problem areas, anti-static floor coverings and ionized air blowers are recommended. Wear clothing resistant to charge creation.

ACKNOWLEDGEMENT

This article was adapted from ILX Lightwave Application Note AN03 by Doug Hodgson and Bill Olsen; see https://goo.gl/HpKTIW.

Aaron Browning is the product specialist for ILX Lightwave Instruments, Bozeman, MT; (406) 556-1246; e-mail: [email protected]; www.newport.com/b/ilx-lightwave.