Ultrafast Lasers: Enhancing ultrafast: Direct diode-pumped Ti:sapphire laser systems

STERLING BACKUS, HENRY C. KAPTEYN, MATT KIRCHNER, and MARGARET M. MURNANE

Without question, the development of the titanium-doped sapphire (Ti:sapphire) laser gain material for femtosecond pulse generation has transformed ultrafast science. Ultrafast laser pulses require a broad spectral bandwidth—and Ti:sapphire, with its gain bandwidth spanning the near-infrared (near-IR) from <700 to >1000 nm, is the champion in this regard.1 Combined with the robustness and high thermal conductivity of the sapphire host material and its excellent ability to store energy compared with other broadband laser media such as dyes, Ti:sapphire is the basis for everything from modelocked ultrafast lasers for biomicroscopy, to systems that can generate amazing peak powers into the petawatt (1015 W) range with pulses a few optical cycles in duration.2,3Ti:sapphire lasers have enabled entirely new technologies and fields of investigation—for example, in the use of high-order harmonic generation (HHG) to produce coherent extreme-ultraviolet (EUV) and x-ray light on a tabletop, making possible studies that previously required going to a synchrotron facility, or were simply not possible.4,5Frequency-comb technology, which was recognized in the 2005 Nobel Prize for physics, was also first demonstrated using an ultrafast Ti:sapphire laser.6,7 Furthermore, through a variety of nonlinear processes driven by Ti:sapphire lasers, pulses as short as 3 fs have been obtained in the visible, and 60 attoseconds in the EUV.

Nevertheless, although Ti:sapphire has been the reigning champion in ultrafast for more than two decades, in recent years other technologies have made inroads. For example, fiber lasers are now generating pulses <100 fs in duration (including the briefcase-size KMLabs Y-Fi fiber laser-amplifier), as are other ytterbium (Yb)-crystal based lasers.

But why use these other technologies? It comes down to a tradeoff of cost and complexity with tunability and pulse duration. Fiber and Yb lasers can be pumped directly with diode lasers, while Ti:sapphire lasers require green light, typically from a 532 nm frequency-doubled neodymium:YAG (Nd:YAG) laser. Although modern pump lasers are now laser-diode-pumped, the cost (~$20,000 ≥ $100,000) is substantial. In addition, the complexity of this approach means that Ti:sapphire lasers are less reliable and need more hands-on maintenance.

A second consideration is that the broad bandwidth of Ti:sapphire requires a large wavelength interval between the pump light and the laser light—that is, a large quantum defect. This also means significant thermal dissipation. In Yb-doped lasers (including Yb-fiber), the quantum defect is several times smaller, as is made possible by the far-narrower gain bandwidth. Furthermore, in a fiber laser, thermal dissipation can be mitigated by distribution over long material lengths. Thus, the tradeoffs are 1) cost and reliability, and 2) pulse duration vs. average power.

Direct diode-pumped Ti:sapphire lasers

However, the necessity for such tradeoffs may now be diminishing as a result of the development of direct diode-pumped Ti:sapphire (DDPTS) laser technology. Starting in the 2000s, another Nobel Prize-winning technology—gallium nitride (GaN)-based optoelectronics—has made it possible to efficiently generate UV, blue, and green light for pumping. In the early 2010s, laser diodes based on GaN started to reach output power levels of >1 W at 445 nm. With this innovation, a group at the University of Strathclyde (Glasgow, Scotland), led by Alan Kemp and Keith Roth, demonstrated the very first femtosecond DDPTS laser.8 While the initial performance was modest, this was a breakthrough, as it showed that such a laser was in fact feasible.

In our subsequent work at KMLabs in collaboration with Charles Durfee at the Colorado School of Mines (CSM; Golden, CO), we demonstrated furthermore that the Kerr lens modelocking (KLM) process that has been so successful in generating few-cycle pulses in Ti:sapphire can also be reliably implemented for direct diode-pumping, with due consideration for the particular beam characteristics of the pump laser (see Fig. 1).9 This means that the ~$50,000 continuous-wave (CW) green lasers that we used in the 1990s can be substituted with a diode costing a few hundred dollars. Since the time of our first demonstration, growth in the power available from UV, blue, and now green laser diodes has continued. It is now possible to use a single inexpensive 4 W laser diode to pump a modelocked Ti:sapphire laser generating pulses as short as 13 fs.10

First DDPTS laser-amplifier demonstration

The second breakthrough has been our recent demonstration of a direct diode-pumped Ti:sapphire ultrafast laser amplifier system.11 To generate the highest peak powers, short pulses from a modelocked laser are injected at a reduced repetition rate into a power amplifier that increases the pulse energy by three to 10 orders of magnitude via a master oscillator power amplifier configuration using chirped-pulse amplification.

In contrast with pumping of the modelocked laser, where the primary objective is simply to make a short pulse, amplifier systems are all about power—both peak and average power. Typically, pulsed frequency-doubled lasers for pumping of the highest peak-power Ti:sapphire systems use large numbers of laser diodes to pump the medium. Furthermore, Nd requires relatively low pump brightness to generate substantial laser gain. In Ti:sapphire, however, the broad bandwidth is necessarily accompanied by the need for high pump brightness. The ability to combine laser diodes while preserving source brightness is a key requirement.

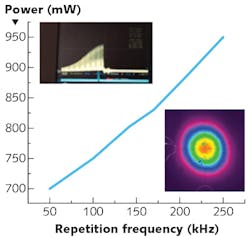

Recently, KMLabs and CSM demonstrated the first regenerative amplifier pumped by a fiber-coupled diode 450 nm laser module. The pump module, from DILAS (Mainz, Germany), combines the power from a large number of single emitters, concentrated to 50 W emitted from a 0.22-numerical-aperture (NA) 200-μm-diameter fiber. This brightness is enough to overcome cavity loss and allow for operation of a regenerative amplifier for ultrafast pulses. In our first work, we obtained >1 W output at amplifier repetition rates of >50 kHz (see Fig. 2).Another key enabling technology in this work was our use of patented cryogenic cooling technology for the Ti:sapphire crystal.12 Cryogenic cooling increases both the lifetime of the Ti:sapphire excited state and the thermal conductivity of the sapphire host medium—the combined effect of which allows operation of the amplifier. As the brightness of these modules further increases, the threshold and overall efficiency will continue to improve. Further work has also demonstrated pumping of the amplifier with spectrally and/or spatially single-emitter diodes.

What's in the future?

The future for DDPTS laser technology is bright, in large part because development of the pump diodes is driven by consumer applications. The LED bulbs that have recently displaced Edison's incandescent bulb use blue LEDs coupled with a phosphor to reliably, efficiently, and economically generate white light. Blue laser diodes are a direct descendent of these blue LEDs—furthermore, advanced consumer lighting applications are already beginning to employ blue laser technology.

Where it is desirable to produce carefully sculpted illumination, blue diode lasers can be focused onto a phosphor to create a brilliant point source of white-light illumination. Applications include laser-driven auto headlights—which allow for brighter illumination of the road while avoiding blinding oncoming traffic—and laser-driven LCD business and theater projectors. As costs come down and efficiency increases, laser-driven illumination is likely to become ubiquitous. In fact, LED-pumped Ti:sapphire is also a possibility.

Thus, in contrast to diode-pumped solid-state Nd- and Yb-doped lasers-which require IR laser diodes whose primary application is for lasers—direct diode-pumping of Ti:sapphire can benefit from a far-larger economic driver. This is already seen in the power available from single-emitter lasers, which have increased by about a factor of five in the past few years, with their prices similarly decreasing.

It is fully conceivable that the costs per watt of blue laser pump light will fall below, and efficiency above, that of IR diode lasers in coming years. This may mean that the highest-performance, highest peak- and average-power ultrafast lasers, running at repetition rates of tens of kilohertz and above, and with overall power measured in kilowatts, may well be DDPTS. This would open up industrial applications, such as the generation of high-power coherent EUV light at 13.5 nm for nanoimaging in support of EUV lithography.13 Even the large quantum defect of the Ti:sapphire material may be ameliorated—very preliminary measurements of fluorescence from Ti:sapphire indicate that some of this energy may be recovered in further laser excitation.

For many applications that require pulses at lower repetition rates better matched with the energy-storage lifetime of Nd- and Yb-doped materials (on the order of milliseconds rather than 5 μs for Ti:sapphire), and for very compact ultrafast fiber lasers, a variety of ultrafast technologies will continue to coexist and be successful in the marketplace. However, past predictions of the demise of ultrafast Ti:sapphire technology are clearly now premature.

ACKNOWLEDGEMENT

Y-Fi is a trademark of KMLabs.

REFERENCES

1. P. F. Moulton, J. Opt. Soc. Am. B, 3, 1, 125–133 (1986).

2. M. D. Perry et al., Opt. Lett., 24, 3, 160–162 (1999).

3. K. Yamakawa and C. P. J. Barty, IEEE J. Sel. Top. Quantum Electron., 6, 4, 658–675 (2000).

4. J. Zhou et al., Phys. Rev. Lett., 76, 5, 752–755 (1996).

5. A. Rundquist et al., Science, 280, 5368, 1412–1415 (1998).

6. D. Jones et al., Science, 288, 5466, 635–639 (2000).

7. T. Udem et al., Opt. Lett., 24, 13, 881–883 (1999).

8. P. W. Roth et al., Opt. Express, 20, 18, 20629–20634 (2012); http://dx.doi.org/10.1364/oe.20.020629.

9. C. G. Durfee et al., Opt. Express, 20, 13, 13677–13683 (2012).

10. S. Backus et al., "Direct diode-pumped Kerr lens 13 fs Ti:sapphire ultrafast oscillator using a single blue laser diode," submitted for publication (2017).

11. S. Backus et al., Opt. Express, 25, 4, 3666–3674 (2017); http://dx.doi.org/10.1364/oe.25.003666.

12. S. J. Backus, H. C. Kapteyn, and M. M. Murnane, "Ultrashort pulse amplification in cryogenically cooled amplifiers," U.S. Patent #6804287 (Oct. 12, 2004).

13. D. F. Gardner et al., "Sub-wavelength coherent imaging of periodic samples using a 13.5 nm tabletop high harmonic light source," Nat. Photon., in press (2017).

Sterling Backus, Henry C. Kapteyn, Matt Kirchner, and Margaret M. Murnane are all with Kapteyn-Murnane Laboratories (KMLabs), Boulder, CO; e-mail: [email protected]; http://kmlabs.com.