Photonics Applied: IR Optics Manufacturing: Laser-assisted μ-LAM process cuts through infrared optics

DEEPAK RAVINDRA, SAI KUMAR KODE, and CHRIS STROSHINE

A wide range of materials, including metals and alloys, ceramics, glasses, semiconductors, and composites, are manufactured to meet service requirements to a given geometry, accuracy, finish, and surface integrity. Metals and alloys in general are easier to machine because of their high fracture toughness, low hardness, non-directional bonding, low porosity, large strain to fracture, and high impact energy. On the other hand, non-metals such as ceramics, semiconductors, optical crystals, and many infrared (IR) optical materials are characterized by covalent or ionic bonding, limited slip systems for plastic deformation, high hardness, and low fracture toughness, making them more challenging to machine.

A new technology called micro-laser-assisted machining (μ-LAM) is gaining traction for machining optical crystals and IR materials including silicon (Si), calcium fluoride (CaF2), zinc selenide (ZnSe), germanium (Ge), and zinc sulfide (ZnS). As evidenced by a materials study undertaken at Micro-LAM, the value proposition for μ-LAM technology includes extended tool life, increased productivity, and improved part quality during the manufacture of optical crystals and IR optics.

Laser-assisted machining

The μ-LAM technology directly heats and thermally softens the workpiece material, in the chip deformation and generation zone, increasing the material's ductility. Improved ductility that results from reduced material hardness allows for easier chip formation, decreased brittleness, and ultimately higher material removal rates-all leading to better tool performance and increased productivity that in turn translates into lower manufacturing costs.

To evaluate the machinability of optical-grade crystals via the μ-LAM process, machining tests were performed on a diamond-turning ultra-precision lathe (UPL) with a 15 pm positional accuracy feedback system. Such UPLs are designed for producing optical lenses, optical mold inserts and mirrors, and small precision mechanical components.

For our analysis, the μ-LAM system was mounted on a UPL to machine a diffractive Si lens (see Fig. 1). The μ-LAM system's tool post, termed Optimus T+1, is a bolt-on system that replaces the existing tool post and takes <60 min to retrofit. The laser controls are connected to the UPL, enabling it to be controlled with an M-code command.

The Optimus T+1 was coupled to a 1064 nm yttrium aluminum garnet (YAG) laser via a fiber-optic cable and collimated lens. The diamond tool is optically transparent to the wavelength of the laser and fabricated to perform as a focusing lens that directs the beam precisely to the tool's cutting edge radius. This allows for only the cutting zone of the material to be heated and softened.

After optimizing such machining parameters as the depth of cut, cross feed, cutting speed, and laser power, several Si lenses were fabricated and evaluated for their surface finish (roughness), surface aesthetics (spokes, brittle bands), form accuracy or irregularity tolerance, tool life (based on the number of parts fabricated), and productivity (pushing the machining parameters to enhance production).

Direct comparison

Optical-grade Si is typically used as a lens for IR imaging systems. Previously, Ge was a favored material, as it is typically easier (softer) to machine. However, there are several advantages of Si over Ge, such as lighter weight, lower cost for the bulk material, and better thermal stability and mechanical properties-primarily higher hardness.

Although the increased hardness in Si is preferred to minimize part failure during service, it also makes it much more difficult to machine. The hardness and abrasiveness of Si causes the diamond tool to rapidly wear, yielding poor part quality and high form errors. The μ-LAM process has shown significant benefits in machining Si and other optical crystals, as it temporarily reduces the workpiece material's hardness, resulting in significantly less tool wear.

A typical Si diffractive lens used in an IR optical system with a 50.4 mm diameter, for example, has a 0.5 fringe irregularity tolerance, surface roughness <10 nm Sa, 60-40 surface quality, no spokes, and no gray or brittle bands. The primary challenge here is achieving the 0.5 fringe (<160 nm) irregularity tolerance that can only be achieved with a well-preserved (not worn) cutting tool edge.

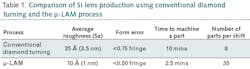

Compared to standard diamond turning, the μ-LAM process not only produces good Si part quality with more than 3X reduction in surface roughness, but it also enables increased manufacturing productivity, more than quadrupling the number of parts that can be produced in a single shift (see Table 1).

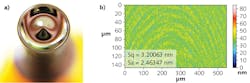

To demonstrate extended tool life, many Si diffractive lenses were machined using the μ-LAM process and analyzed for surface roughness and form error using a white light interferometer with a standard Gaussian 0.08 mm filter applied. Note that the part numbers correspond to the order in which they were machined—for example, part 12 would be the 12th part the tool would have machined.

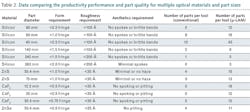

Of the three parts (numbers 4, 11, and 12) randomly chosen and analyzed, average roughness values were 1.368, 1.105, and 0.805 nm Sa and all with <0.5 fringe and no spokes, and no gray or brittle bands (see Fig. 2). Preservation of the surface quality from parts 4 to 12 suggests that the tool has not degraded during the μ-LAM process.In addition to Si, the μ-LAM process also improves productivity for other crystals and IR materials (see Table 2). μ-LAM is also an enabling technology, producing high-quality, large-diameter Si optics and all sizes of CaF2 optics compared to zero acceptable parts using conventional diamond turning alone.

Tungsten carbide breakthrough

Recently, μ-LAM technology has made some groundbreaking progress in machining optical-quality tungsten carbide (WC) using a diamond-turning process. While favored in the glass molding industry, as it performs well under high temperature and high-pressure applications, WC is an extremely hard material (about 3X harder than Si) and, therefore, has never been successfully diamond-turned to an optical quality surface. The status-quo process to manufacture WC optical molds is to grind and polish them in an arduous 3–4 hour per-part process.

Micro-LAM has developed a process incorporating μ-LAM technology that can manufacture an optical-quality WC mold via laser-assisted diamond turning, taking minutes vs. hours. The quality of these μ-LAM-produced lenses is also well within the required specifications that eliminate the need for post-processing steps such as polishing (see Fig. 4).For a 17-mm-diameter WC part, machining time is 90 seconds. With a required Sa spec for this <5 nm part, the μ-LAM process yielded roughness values of 2 to 2.5 nm.

With a less-than-eight-month payback, the μ-LAM system is proving its worth for many IR optical materials and crystals, with productivity improvements up to 500%, machine efficiency increases up to 200%, and improved part quality. μ-LAM processes are also being developed for ultrahard materials such as silicon carbide (SiC), sapphire, spinel, glass, and some selected metals used in the optics and aerospace industries.

Deepak Ravindra is CEO, Sai Kumar Kode is lead process engineer, and Chris Stroshine is global sales manager, all at Micro-LAM, Portage, MI; e-mail: [email protected]; www.micro-lam.com.