Laying the groundwork for industrial 3D-printed parts

Oil and gas operators have become increasingly open to considering metal additive manufacturing (also known as 3D printing) as a potential answer to challenges that include part-inventory lead-time delays, component obsolescence, and remote locations. Original equipment manufacturers (OEMs) to the industry are also looking to additive manufacturing as they evolve along with their operator-customers to achieve more efficient, cost-effective solutions that address ongoing inventory and geographic roadblocks.

There remain, however, some significant obstacles to the widespread adoption of additive manufacturing in the oil and gas industry.

Most existing metal additive manufacturing technologies are still unable to efficiently and rapidly adapt to changing geometries and features. They often require significant redesign of a part in order for it to be printable, rather than allowing for a part be printed as originally designed. Data from throughout the printing process is often not available, which is critical to assess the quality of the end part.

What’s more, a print file set up on one additive manufacturing machine can’t be used on another one—sometimes even if they are the same make and model—without user intervention; the result can be an ever-changing file based on individual machine calibration. This creates a digital inventory challenge similar to the current physical inventory one that oil and gas operators are already dealing with.

There have also, until very recently, been no published guidelines from the American Petroleum Institute (API; Washington, DC) for the procurement or specification of additive manufacturing materials. “This has been a challenge for users interested in applying more advanced industrial additive manufacturing technology to applications where the speed and quality it can deliver would be beneficial,” says Steve Freitas, R&D director at IMI Critical Engineering (Birmingham, UK). The company designs, manufactures, and installs customized, highly engineered flow control solutions for new plant builds, and provides comprehensive plant lifecycle service support.

However, guidance has now begun in the form of API20S, the first-ever oil and gas industry-sanctioned specification for metal additive manufacturing. Published October 19, 2021, this spells out processes, testing, documentation, and traceability among other requirements for metal additive components produced for use in oil and gas facilities of all types.

The API20S draft leveraged input from hundreds of companies, including operators, OEMs, and additive manufacturing machine makers. While not detailing complete success criteria (that is, required mechanical or nondestructive testing acceptance criteria), API20S does outline what kinds of testing and validation will be required depending on different risk levels within an oil and gas operation.

IMI Critical is among those welcoming the guidelines enthusiastically, as they began looking at different additive manufacturing systems for 3D printing of valves several years ago. “But it’s only recently that we’ve identified the advanced additive manufacturing technology that really delivers on its promise,” says Freitas.

Velo3D (Campbell, CA) is the additive manufacturing system manufacturer providing the needed level of advanced additive manufacturing technology to IMI Critical. Partnering with a major oil and gas operator that is also an API committee member, IMI Critical has now delivered highest criticality (Additive Manufacturing Specification Level 3), first-article component-builds intended for field service. The parts, which also meet API20S requirements, were printed on a Velo3D Sapphire additive manufacturing system operated by contract manufacturer Knust-Godwin (Katy, TX).

Velo3D is known for its full-stack additive manufacturing solution that includes automated pre-build system calibration and end-to-end build-quality monitoring and reporting—features that deliver exactly the kind of data on which many of the objectives of API20S are based. The long-term goal of the joint project is to build up a compendium of measured field data that will support the path towards certification of production parts for additive manufacturing, as well as the future establishment of more exact specifications for material properties and test methods.

For the team project, the oil and gas operator selected a commonly installed choke valve cage. The part had been manufactured with simple slotted holes for ports, which can have problems with vibration and damage due to trim erosion in high-pressure-drop operations.

The flow-control industry has evolved considerably between the time this legacy part was created and today. One innovation is IMI Critical’s DRAG technology, which consists of an array of discrete, multi-stage flow paths that better control fluid velocity and prevent problems with vibration and trim erosion. IMI Critical, having produced metal additively manufactured components for years, saw a business opportunity to not only replace a part on-demand, but also to improve its performance with DRAG.

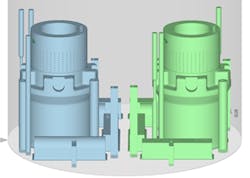

The next step was to assess the new design for 3D printing out of Inconel 718 (see Fig. 1). “Velo3D’s early review of our cage design produced valuable recommendations on how to improve the quality of both the as-built additively manufactured part and the final, post-processed machined part,” says Freitas.

Getting ready to print

With the CAD design for the part complete, it was time to move to additive manufacturing. Unlike other metal additive manufacturing systems, Velo3D’s Flow print-preparation software automatically responds to a part’s geometry without any complex part-specific parameter development. Flow does this by applying a generalized set of recipes based on the design’s native CAD geometry and user-defined inputs relating to surfaces of importance. This allows design engineers to focus on their desired end-part functionality above all, without the need for complex, pre-print parameter manipulation.

The designer can also use the software to easily apply and test different surface-refining sub-processes to choose the best one. This not only resulted in a quick transition into the first-article section of the project, but it also created a standardized framework to further ease setting up future builds to meet IMI Critical’s specific surface finish and flow characteristic requirements.

“Flow greatly reduces the initial setup time from CAD to print file,” says Zach Walton, director of energy solutions for Velo3D, who worked closely on the project with IMI Critical. “This opens up the ability for design and manufacturing engineers to more easily and efficiently implement metal additive manufacturing. At the same time, our system’s ability to print the same build file on any Velo Sapphire machine, no matter where it is in the world or who is operating it, was very appealing to the oil and gas operator’s vision for digital inventories and direct part replacement.”

Quality control throughout the print process—and reproducibility anywhere

The automation provided by Velo3D’s internal quality-control software, Assure, was highly beneficial. “Following one-click calibration before a build, Assure compiles that data along with a tremendous amount of information collected throughout the build, layer by layer, then automatically generates a build report containing the information of importance,” says Walton.

“The raw data and height-mapper images (see Fig. 2) were also useful for evaluating and assessing critical areas of the part for future production. In conjunction with the Flow pre-print software, this allows for this same print file to be printed on any Velo3D system no matter who is operating it or where it is in the world—with the same expected end-part quality. These capabilities of advanced additive manufacturing now make digital warehousing and on-demand part replacement achievable.”“Now we can help our customers reduce inventory requirements while providing opportunities to optimize both the functional characteristics and the materials of critical process-control components,” Freitas says. “This allows oil and gas operators to shift their focus away from repair and part supply chain problems and concentrate on improving plant reliability and controlling costs.”

The two First Article choke valve components were successfully printed at the Knust-Godwin facility (see Fig. 3a). From there, the valves were removed from the build plate along with the API20S test specimens. The valves were then machined to final finish (see Fig. 3b) while specimens were tested in accordance with API20S, which showed compliance to IMI Critical’s materials specification.The valves were then flow-tested at IMI Critical before being delivered to the oil and gas operator for use in upcoming field trials.

With initial testing and analysis deemed successful, these versions are in transit to be run in the field by the oil and gas operator. Production builds are currently ongoing, leveraging the manufacturing plan established during the First Article build. Additional field testing will also be performed to collect more operational data. The result will be production-ready components, adhering to current API20S standards, that will be put through real-world field trials at one of the operator’s sites.

ACKNOWLEDGMENT

DRAG is a registered trademark of IMI Critical Engineering.

Lynn Manning | President, Parker Group

Lynn Manning is president of Parker Group (Providence, RI). She has more than 25 years’ professional experience in public relations with both domestic and international agencies as well as her own consultancy. Elected to the scientific research society Sigma Xi upon receiving her Sc. B. from Brown University, Manning has written about scientific, technical, and medical subjects for three decades.