IAN JONES

Lasers are very attractive tools for joining sheet, film, and molded thermoplastics and textiles. Their features allow for a precise, yet rapid, delivery of a controlled amount of energy exactly to the point where it is required. Lasers are available with outputs covering a range of wavelengths, which has a large bearing on the interaction of the light with plastic materials. The nature of the process used is varied depending on the type, thickness, and additives in the plastics. Complex forms can be welded using high-resolution positioning and welds from <100 μm wide. This makes them suitable in a wide variety of applications, including catheters, microfluidic devices, tubing, packaging, electronic cases, and inflatable devices by using different material handling equipment.

Plastic types

Thermoplastics are polymer materials made from long-chain molecules that, above a certain temperature, can be reshaped or welded. Unlike thermoset polymers, which cannot be melted, the molecular chains in thermoplastics are not cross-linked and do not have a rigid network. At high temperature, the molecules are free to move and the material flows as a liquid. Industrial plastics have melting or softening temperatures in the 120–343°C range.

Thermoplastics may be split into semicrystalline (milky appearance) and amorphous (glassy) types. Semicrystalline types are a mixture of small crystallites surrounded by amorphous material. The crystallites scatter light, giving rise to their outward appearance and limiting the transmission of laser radiation. This, in turn, limits the maximum thickness that may be transmission laser-welded. Some plastics can be made in both types, but this is generally not the case. Plastics such as polyethylene (PE), polypropylene (PP), nylon (PA), and polyetheretherketone (PEEK) are semicrystalline, while polycarbonate (PC), polymethylmethacrylate (PMMA), and polystyrene (PS) are amorphous.

Laser types and their interaction with plastics

The different applications possible with each laser type are very dependent on the wavelength of light produced, which dictates the form of energy absorption in the plastic.

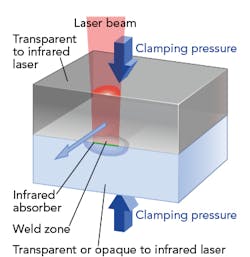

The most common form of laser welding is the transmission method, in which the beam is delivered through the upper part to the surface of the lower part where heating and melting takes place. The differential heating is controlled using laser-absorbing additives or coatings at the lower part. A laser with a wavelength in the 750–1500 nm range is used and this may be provided by diode, fiber, and neodymium-doped yttrium aluminum garnet (Nd:YAG) laser types. In general, this wavelength of radiation is absorbed far less readily in plastics than ultraviolet (UV) or mid-infrared (mid-IR) radiation. The degree of energy absorption in this range depends largely on the presence of additives in the plastics and whether the plastic is semicrystalline or amorphous. If no fillers or pigments are present in the plastic, the laser will penetrate a few millimeters into semicrystalline plastics and is hardly attenuated at all in amorphous plastics. The absorption can be increased by means of additives such as pigments or fillers, especially carbon-black pigment.

The absorption of radiation by natural unpigmented plastics increases from 1.6 µm wavelength upwards until there is very strong absorption for IR wavelengths longer than 5 µm. At a wavelength of 2 µm, which may be provided by a fiber laser or holmium:YAG laser, the energy from the beam is deposited in the top few millimeters of all plastics (semicrystalline or amorphous). Welding is possible in sheet up to a few millimeters thick without the need for additional absorbers. This is termed direct laser welding because the beam is not transmitted through an upper part to the joint line. Direct laser welding is not yet widely applied for joining plastics, but has potential for wider use.

The carbon-dioxide (CO2) laser is a well-established materials processing tool commonly used for cutting plastics in film, sheet, and fabric form. The CO2 laser radiation (10.6 µm wavelength) is rapidly absorbed in the surface layers of all plastics. The energy is delivered as heat in the first 0.2 mm of plastic to which the laser is directed. This leads to rapid heating and very rapid weld processing of thin plastic film is possible, even with fairly modest laser powers (<1000 W). Welding speeds in excess of 1000 m/min have been demonstrated.

Transmission laser welding

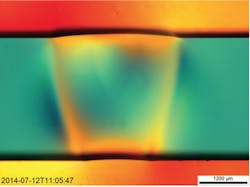

When first being reported in 1985, transmission laser welding was carried out with an IR transmissive plastic material for the upper section and a carbon-black loaded plastic for the lower layer. The carbon black absorbs and heats in the laser beam to generate a weld at the interface between the two pieces. The process is limited by the fact that one side of the component has to be black, but is still the most common application of the process. The upper part must transmit a proportion of the laser energy (more than 10% is usually enough) so that heating preferentially takes place at the surface of the lower part rather than at the upper surface of the top part (FIGURE 1). This image, with an almost equal melt depth in the two materials, shows that heating is developed very locally at the black surface. The black surface acts as a heating element within the part and provides for rapid processing, minimal thermal damage of surrounding components, and minimal distortion or contamination at the joint.Application areas for transmission laser welding include:

- Medical devices

- Packaging

- Automotive components

- Consumer products

- Electronic packages

- Textiles

The process has also been extended to joining of fiber-reinforced polymer composites. The composite matrix is heated and melted by the laser source, while the fiber reinforcement remains unaffected by the process.

Transmission laser welding can be applied to composite materials with glass or polymer fiber reinforcement, and matrices that do not have high filler content. When carbon fiber is used or the matrix is black or heavily filled, the direct laser welding method may be used, which does not require the beam to pass through the part.

Direct laser welding

When laser energy is not transmitted, either through choice of radiation wavelength or because of the materials selected, melting starts at the upper surface of the plastic. The consequent joining method is known as direct laser welding. The CO2 laser was first used for this process, and welding of thin film is possible at very high speeds. Welding has been demonstrated with a range of plastic films at speeds of up to 1200 m/min. A simultaneous cut/seal may also be carried out for packaging or bag-making purposes by controlling the laser-beam power distribution to cut two films in contact while leaving a welded region at the edge of the cut.

For plastics with thicknesses in the 0.2–5 mm range, a source with 2–3 µm wavelength may be used to make conventional butt joints (FIGURE 5) and other joint configurations. There is no need for additional absorber, but the plastic transmission properties must be controlled to ensure consistent welding takes place.Summary

Polymer products can be laser-welded using a variety of process mechanisms (matching materials with radiation wavelengths) and alternative equipment configurations such as gantry, robotic, scanner, or fixed diode arrays. The laser provides an efficient energy source to give precise heating and localized melting. The welds are completed rapidly, with high strength and good appearance.

The welding process is efficiently achieved using very compact diode and fiber laser sources, and lends itself easily to high levels of automation. Applications of this technology exist for a wide variety of industry sectors and product types.

IAN JONES ([email protected]) is the manager of Laserweld Plastics, Oswestry, England; www.laserweldplastics.com.

EDITOR’S NOTE: This article was reprinted from The Laser User, Issue 87 (Winter 2018), with permission from the author and The Association of Laser Users (AILU); www.ailu.org.uk.