Nanoscale laser isolator could revolutionize photonics devices

In a paper in Nature Photonics, Jelena Vučković, a professor of electrical engineering, and colleagues report a way to overcome the long-standing tradeoff between efficiency in laser stabilization and large, complex, power-hungry systems.

Optical isolators are critical devices widely incorporated into laser systems that pass coherent light in only one direction, while blocking unwanted reflection from returning into the source. Isolating the desired signal in this way stabilizes and protects the laser from damage, eliminating mode hopping, amplitude modulation, frequency drifting, and other undesirable feedback.

A chip-based approach involving complementary metal-oxide semiconductor (CMOS) fabrication is the holy grail of many an application in photonics, due to its common use and potential for inexpensive mass production. It’s no different here. An isolator on a semiconductor chip would enable a passive solution to achieve the desired, very narrow linewidth. A chip could then easily be incorporated as part of a laser system.

“Narrow linewidth lasers are important for quantum computation systems,” says Geun Ho Ahn, co-author and doctoral student in Vučković’s group. “And integrating all these pieces on a chip is the most promising way to scale up these systems. Furthermore, passive operation is critical in quantum systems due to their extreme sensitivity to environmental noise.”

Existing chip-scale solutions rely either on a strong external magnetic field, or external modulation drivers that consume power. These solutions can be complex, hard to fabricate, and can create noise that muddles the signal.

“With magnetic- or modulation-based isolators, excess magnetic fields and RF radiation can cause inhomogeneities and decoherence in quantum experiments,” says Ahn. An ideal solution would be nonmagnetic, have no other external parts, and still be compatible with CMOS fabrication.

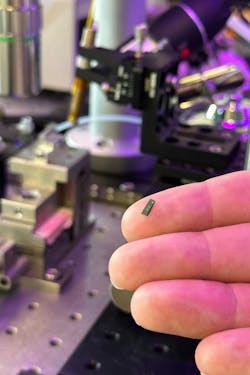

Vučković set out to demonstrate optical isolation using ring resonators, which would be fully passive and require no power beyond the laser source itself (see Fig. 1). Ring resonators, which are made of CMOS-compatible thin-film silicon nitride, offer optical nonlinearity via the use of the nonreciprocal optical Kerr effect. The ring resonator cavity allows the incoming desired laser light to build up power, circulating in a clockwise fashion, strengthening via resonance until it transmits at near-unity power levels. This large power in the ring, in conjunction with the Kerr effect, shifts the counterclockwise resonance far away in frequency. This frequency shift of the counterclockwise resonance prevents any back-reflected light from resonating and transmitting—which provides isolation.

Next steps

To test the design, the Stanford team and colleagues at the University of California, Santa Barbara directly butt-coupled the isolator to an edge-coupled 1550 nm distributed feedback (DFB) laser chip. The prototype demonstrated single-ring isolation of 17 dB with an insertion loss of only 1.8 dB. Cascading two isolators on the same chip enabled an overall isolation ratio of 35 dB with an insertion loss of 5 dB (see Fig. 2).

“We are taking advantage of the long lifetimes in our devices and the potential for well-controlled fabrication to self-injection lock our source laser, reducing its linewidth while simultaneously isolating its output,” says Alex White, co-author and doctoral student researcher.

The new isolator could be used to improve performance and miniaturize all kinds of laser systems, from turnkey frequency combs to terabyte communications, on-chip optical amplifiers, and quantum computing systems.

Vučković and her team are continuing to improve the isolator, fabricating and testing prototypes at shorter wavelengths of 780 nm and 1064 nm. They’re also working on integrating the isolators more directly with laser systems. The new work aims to improve laser power more than previously possible, and to enable turnkey lasing on the isolator resonance upon startup, alleviating the need for active laser tuning.

“With more precise integration, we can combine the benefits of narrow linewidth external-cavity lasers and isolation all in one device with turnkey operation,” says White. “If successful, we believe these integrated and isolated lasers could replace the bulkier packages currently ubiquitous in communication systems, and future work combining the isolators with frequency comb sources can push this even further.”

The resulting simplicity could be revolutionary in enabling ubiquitous, low-power photonics devices.

Valerie Coffey-Rosich | Contributing Editor

Valerie Coffey-Rosich is a freelance science and technology writer and editor and a contributing editor for Laser Focus World; she previously served as an Associate Technical Editor (2000-2003) and a Senior Technical Editor (2007-2008) for Laser Focus World.

Valerie holds a BS in physics from the University of Nevada, Reno, and an MA in astronomy from Boston University. She specializes in editing and writing about optics, photonics, astronomy, and physics in academic, reference, and business-to-business publications. In addition to Laser Focus World, her work has appeared online and in print for clients such as the American Institute of Physics, American Heritage Dictionary, BioPhotonics, Encyclopedia Britannica, EuroPhotonics, the Optical Society of America, Photonics Focus, Photonics Spectra, Sky & Telescope, and many others. She is based in Palm Springs, California.