ORGANIC PHOTODETECTORS: Single-layer polymer pixel senses three colors

A single layer of polymer in an optical sensor developed by researchers at the Jawaharlal Nehru Centre for Advanced Scientific Research (Bangalore, India) can sense multiple colors without using color filters, subpixelation, or an external bias voltage.1 The way the device works is similar in some ways to the function of retinal cone cells and other biological color sensors.

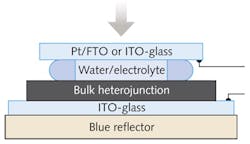

The approach relies on the use of a water/electrolyte layer included within the device that creates wavelength-specific transient responses. The binary donor-acceptor forming the sensor’s bulk heterojunction (BHJ) structure has a so-called regioregular alkylthiophene (a conducting polymer) as the donor and N2200 (a dark blue ink used in liquid-crystal displays) as the acceptor. The mixture was cast in a film on indium tin oxide (ITO)-coated glass substrate at thicknesses ranging from 200 nm to 6 µm for experimentation. The fluid layer contained water with potassium chloride as the electrolyte. The second electrode, in contact with the water layer, was either ITO-coated or fluorine-doped tin oxide (FTO)-coated glass, both versions with a platinum (Pt) coating (see figure).

For thick BHJ films, the transient generated signal is positive; for thinner BHJ films the transient signal is negative. When the film is at the critical thickness, the transient characteristics depend on the color of the light. This optimum thickness was arrived at through experimentation and depends on the donor/acceptor ratio: For a 4:1 ratio, the critical thickness was about 2 µm.

Transient decay times are key

This results in only a two-color detector, however. To create a tricolor-response detector, the difference in transient response with color is heightened with a blue-selective Bragg grating below the ITO-coated glass. To distinguish colors, exponential decay times in the transients (on the order of tens of milliseconds) were fitted via software for the experiment; however, the researchers believe that analog “demosaicing” can be used for nondigital three-color detection.

Deriving the colors from their transient signals allows pure colors (for example, spectral yellow) to be distinguished from composite colors (such as the yellow arising from the combination of red and green light). For pure spectral colors, the sensor can be used to distinguish more than three colors, and was shown to have a discrimination of about 10 nm over a range of 400–700 nm.

The researchers note that polarity-dependent color discrimination has previously been shown in other very different systems, such as in the purple photoresponsive protein bacteriorhodopsin and others, as well as in chlorophyll. However, the responsivity of the BHJ-based sensor is at least an order of magnitude higher. The researchers add that the time scales of the signals from the BHJ device are similar to those shown by a test on an isolated mammalian retina.

Photosignals from the BHJ sensor show higher sensitivity to blue color on a red background than blue alone, and a higher sensitivity to red color on a blue background than red alone. This adaptation is see in animal and human visual systems.

REFERENCE

1. V. Gautam et al., J. Am. Chem. Soc., (Sep. 27, 2011); doi:10.1021/ja207853e.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.