LLNL and LLE researchers compress iron to 560 GPa with laser multishock compression

Livermore, CA and Rochester, NY--Using the OMEGA laser at the Laboratory for Laser Energetics (LLE) at the University of Rochester, researchers at Lawrence Livermore National Laboratory (LLNL) and LLE have compressed iron to 560 GPa (5.6 Mbar), which is greater than the pressure at the center of the Earth.

Iron is the most abundant element in Earth's core and the sixth most abundant element in the universe. As a key component of terrestrial planets and exoplanets, iron has been one of the most studied materials under extreme conditions.

The record pressure is achieved by dynamic multishock compression. Using a series of shocks (rather than a single shock) keeps the entropy low while compressing the material, which is key to keeping the temperature lower than the melting point and allowing the iron to remain solid. The result is iron with a close-packed structure.

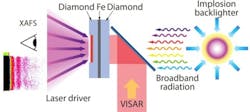

Diagnosing the material properties under extreme conditions is as important as the creation of high-pressure states. The team used extended X-ray absorption fine structure (EXAFS) for the first time in a study on high-energy-density (HED) matter.

Unexpectedly, the team found that the temperature at peak compression is significantly higher than that from pure compressive work. Extra heat is generated by inelastic distortion of the lattice, termed plastic work. It is found that upon fast compression in a few billionths of a second, the strength of iron is enhanced, leading to more plastic work and the elevated temperature.

"It took us more than two years to develop this experimental platform," says Yuan Ping, one of the LLNL researchers. "Now the measurements can be scaled up to larger laser systems, such as the National Ignition Facility, to reach higher pressures or extended to shorter time scale to study dynamics in HED materials."

The research appears in the August 9, 2013 issue of Physical Review Letters.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.