Patterned silica glass layer makes solar cells self-cooling

Scientists at Stanford University (Palo Alto, CA) have increased the ability of silicon (Si) photovoltaic cells to radiate IR light, and thus heat, away during operation, thus lowering the devices' temperature and increasing lifetime and efficiency. They do this by adding patterned layer of silica glass to the surface of conventional Si solar cells. The technology is described in the premiere issue of The Optical Society's (OSA) new open-access journal Optica.1

Under normal operating conditions, solar cells can easily reach temperatures of 55°C or more. These harsh conditions quickly sap efficiency and can markedly shorten the lifespan of a solar cell. Actively cooling solar cells, however (either by ventilation or coolants) would be prohibitively expensive and at odds with the need to optimize exposure to the Sun.

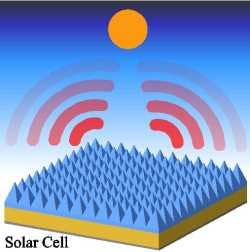

The newly proposed design avoids these problems by taking a passive approach to cooling. By creating microscopic pyramid- and cone-shaped structures on an thin layer of silica glass, the researchers found a way of redirecting unwanted heat (in the form of IR light) from the surface of solar cells, through the atmosphere, and back into space.

Aged cells not wanted

Ordinarily, for every 1°C increase in the temperature of a Si solar cell, the efficiency of a solar cell declines by about 0.5%. In addition, solar cells age more rapidly when their temperatures increase, with the rate of aging doubling for every increase of 10°C.

To passively cool the solar cells, allowing them to give off excess heat without spending energy doing so, requires exploiting an infrared window through Earth's atmosphere.

"Silica is transparent to visible light, but it is also possible to fine-tune how it bends and refracts light of very specific wavelengths," says Shanhui Fan, an electrical-engineering professor at Stanford University. "A carefully designed layer of silica would not degrade the performance of the solar cell but it would enhance radiation at the predetermined thermal wavelengths to send the solar cell's heat away more effectively."

To test their idea, the researchers compared two different silica covering designs: one a flat surface approximately 5 mm thick and the other a thinner layer covered with pyramids and microcones just a few microns thick in any dimension. By precisely controlling the width and height of the pyramids and microcones, they could be tuned to refract and redirect only the unwanted IR wavelengths away from the solar cell and back out into space.

"We were quite pleased to see that while the flat layer of silica provided some passive cooling, the patterned layer of silica considerably outperforms the 5 mm-thick uniform silica design, and has nearly identical performance as the ideal scheme," says Fan. (In the ideal scheme for a bare Si cell, the cell is cooled by 18.3°C.)

The team's next step is to demonstrate radiative cooling of solar cells in an outdoor environment.

REFERENCE:

1. L. Zhu et al., Optica 1, 32-38 (2014); http://dx.doi.org/10.1364/OPTICA.1.000032

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.