Carbon-nanotube-based field emitter aims to be efficient just like LEDs

Electronics based on carbon, especially carbon nanotubes (CNTs), are emerging as successors to silicon for making semiconductor materials. They could possibly also lead to bright, low-power, low-cost lighting devices competing against light-emitting diodes (LEDs) for efficiency.

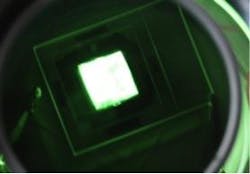

Scientists from Tohoku University (Sendai, Japan) have developed a flat light source that is a field emitter based on carbon nanotubes. Although the device has a diode-like structure, its light-emitting system is not made of layers of semiconductors.1 Instead, the device is based on a phosphor screen and single-walled carbon nanotubes as electrodes in a diode structure.

The researchers assembled the device from a mixture liquid containing highly crystalline single-walled carbon nanotubes dispersed in an organic solvent mixed with a surfactant. Then, they painted the mixture onto the cathode, and scratched the surface with sandpaper to form a light panel capable of producing a large, stable, and homogeneous emission current with low energy consumption.

Fourier analysis of sandpaper scratches

In an interesting approach, the researchers did a Fourier analysis on the sandpaper scratches to determine their period, using sandpapers with different grit numbers (finer versus coarser sandpaper) to find the best period.

"Our simple 'diode' panel could obtain high brightness efficiency of 60 lm/W, which holds excellent potential for a lighting device with low power consumption," says Norihiro Shimoi, the lead researcher and an associate professor of environmental studies at Tohoku University. Currently, LEDs can exceed 100 lm/W, while OLEDs can reach about 40 lm/W (although OLEDs emitting more than 100 lm/W are in the research stage).

In recent years, carbon nanotubes have emerged as a promising material of electron field emitters, owing to their nanoscale needle shape and extraordinary properties of chemical stability, thermal conductivity and mechanical strength.

Highly crystalline single-walled carbon nanotubes (HCSWCNTs) have nearly zero defects in the carbon network on the surface, says Shimoi. "The resistance of a cathode electrode with highly crystalline single-walled carbon nanotubes is very low. Thus, the new flat-panel device has smaller energy loss compared with other current lighting devices, which can be used to make energy-efficient cathodes with low power consumption."

Source: http://www.eurekalert.org/pub_releases/2014-10/aiop-blb101014.php

REFERENCE:

1. Sharon Bahena-Garrido et al., Review of Scientific Instruments (2014); http://dx.doi.org/10.1063/1.4895913

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.