M Squared demonstrates UK's first industrial quantum gravity technology

Photonics and quantum-technology company M Squared (Glasgow, Scotland) has unveiled a commercial quantum device called a quantum gravimeter, which is able to measure gravity. Uses will include the detection of new oil and gas deposits, surveying unknown underground infrastructures such as pipes and cables, monitoring the water table and preventing flooding, and geological surveying.

In the project, called ANAGRAM, which is co-funded by Innovate UK and is part of the UK National Quantum Technologies Programme, M Squared contributed laser engineering and system integration while working with Kai Bongs’ group at the University of Birmingham.

Quantum gravimeter

"A quantum gravimeter can detect and measure atomic interference; a manifestation of wave-particle duality that matter can display when it is in a quantum state at temperatures just above absolute zero," says Graeme Malcolm, CEO and cofounder of M Squared. "It uses quantum technology to bring unprecedented levels of precision to gravitational measurements and the detection of gravitational fields of hidden objects. Quantum gravimetry will bring a range of economic, social, and environmental benefits in the coming years. Applications can be envisaged in many sectors, from the detection of new oil and gas deposits, surveying unknown underground infrastructures such as pipes and cables, even monitoring the water table. If we can transfer the technology into accurate seismic mapping, it could be used to predict natural disasters ranging from avalanches and volcanic eruptions to tsunamis."

Quantum accelerometer

M Squared is also working with Ed Hinds' group at Imperial College London to develop complementary quantum technologies as part of the UK Quantum Technology Programme, a project also funded by the UK Defence Science and Technology Laboratory (DsTL). Co-funded by Innovate UK, the project POLARIS is focused on developing the UK's first commercial quantum 3D inertial sensing device—in other words, a quantum accelerometer. This technology measures acceleration using atom interferometry, with uses including high-precision satellite-free navigation for use in mining, shipping, and other transport means where GPS is hindered by dead areas and the effects of terrain and weather.

Atom interferometer

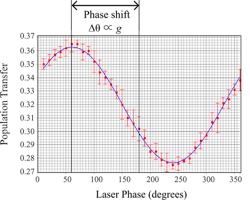

M Squared first developed a magneto-optical trap in 2015, which was the precursor to its commercial atom interferometer launched in 2016—both UK commercial firsts. M Squared's atom interferometer enables high-precision measurements of the influences of motion, gravity, and magnetic and electric fields on clouds of atoms and sits at the heart of a number of cutting-edge quantum technologies.

For more info, see http://www.m2lasers.com/newsevents/news/uk%E2%80%99s-first-quantum-gravity-measurements-outside-academia.aspx

Source: M Squared

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.