Apple (Cupertino, CA) is drawing from its $1 billion Advanced Manufacturing Fund to award Finisar (Sunnyvale, CA), which makes vertical-cavity surface-emitting lasers (VCSELs) and other optical communications equipment, $390 million to create a 700,000-square-foot VCSEL manufacturing plant in Sherman, Texas. The money will allow Finisar to greatly increase its R&D spending and high-volume production of VCSELs for use in Apple's products.

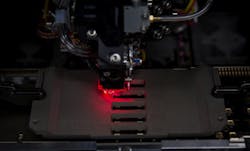

VCSELs are at the heart of Apple's Face ID facial-recognition system for its smartphones; Apple also uses VCSELs for portrait-mode selfies with the iPhone X TrueDepth camera and for the proximity-sensing capabilities of AirPod wireless headphones.

For mass-produced consumer equipment requiring a basic laser, VCSELs can be better performing and more compact and cost-efficient compared to traditional edge-emitting laser diodes. In the fourth quarter of 2017, Apple will purchase 10 times more VCSEL wafers than were previously manufactured worldwide over a similar time period.

Apple's award will create more than 500 high-skill jobs at the Sherman facility, including engineers, technicians and maintenance teams. When combined with the company’s nearby plant in Allen, Texas, Finisar's payroll in Northern Texas is expected to be $65 million. Hiring, capital equipment planning, and infrastructure upgrades are already underway at the Sherman facility, which is expected to begin shipping in the second half of 2018. 100% of the VCSELs Apple buys from Finisar will be made in Texas.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.