NIST radiation-pressure power meter (RPPM) tested with a 50 kW laser

Researchers at the National Institute of Standards and Technology (NIST; Boulder, CO) have been developing a novel laser power meter that makes its measurements using the radiation force exerted by the laser light itself. Called the radiation-pressure power meter (RPPM), the device has previously been tested by NIST researchers using their own highest-power laser, which tops out at 10 kW.

Now, the NIST team has fully tested this instrument using a 50 kW laser at the High Energy Laser Systems Test Facility (HELSTF; White Sands Missile Range, NM), operated by the U.S. Army.

NIST performed the tests at the behest of the U.S. Army and Navy. In particular, the Naval Surface Warfare Center, Corona Division (NSWC Corona), in California has been a critical and founding supporter of this technology.

Instead of acting as a heat sink, as do conventional high-power laser-power meters, NIST's RPPM works by measuring the pressure of laser light on a mirror. For example, a 100 kW laser beam produces a force equivalent to about 68 milligrams (approximately the weight of two staples).

The RPPM contains a high-precision laboratory balance with a mirrored surface with a reflection of 99.999%. Radiation pressure is measured by the balance; the force measurement is then converted to a power measurement.

The HELSTF laser has previously been measured with state-of-the-art heat-sink-style laser power meters, but these have limitations. Each power test takes several minutes to complete. Furthermore, researchers can’t use the heat sink device at the same time that they are doing research with the laser because the measurement devices absorb the laser beam. They also tend to be bulky and heavy, with large power and cooling requirements.

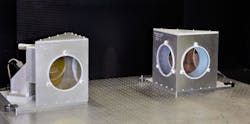

In contrast, the RPPM is small (the unit is about the size of a shoebox), has low power and cooling requirements, and makes its measurements in real time. Since the laser beam bounces off the mirror intact, the light can be used directly for applications. And unlike the heat sink device, the RPPM is a primary standard in itself, meaning it does not need to be compared to other power meters to establish its accuracy.

Taking the heat

For the 50 kW test, the researchers set up infrared cameras and other temperature sensors and found that it performed "perfectly, just the way we would expect," says NIST physicist Joshua Hadler. "We could see a little bit of heat on the mirror, but not much, just a few degrees tops."

Once they were satisfied that the instrument could take the heat, NIST staff used it to perform nearly 300 measurements of the HELSTF laser's power from 1 kW to 50 kW over a two-week period. They found that the RPPM was capable of measuring the power across that entire range with an accuracy of 1.3% to 4.5%.

The researchers also tested the RPPM against several other laser power measurement instruments at HELSTF and found wide variability in the accuracy of ten different detector technologies.

Hadler says the NIST team has an open request to industry and other government agencies who want their high power lasers calibrated with the new RPPM. Meanwhile, there is interest in returning to HELSTF to test the RPPM's accuracy at even higher powers, possibly exceeding 100 kW.

Miniaturized version being developed

On the other end of the application spectrum, NIST researchers are trying to miniaturize the technology. They are currently working on a chip-scale version of the device—called the "Smart Mirror"—which will be used with lower-power lasers from 1 to 1000 W. The smart mirror could potentially be integrated into laser weld heads and additive-manufacturing machines for real-time, continuous laser power measurements.

The RPPM-anchored HELSTF test event was jointly supported by the Office of the Secretary of Defense Test Resource Management Center and the Directed Energy Joint Technology Office.

(Note: A version of the RPPM developed by Scientech (Boulder, CO) jointly with NIST has measured the radiation pressure of 500 kW of light, although this measurement was done in a different way, by recirculating light in a high-finesse optical cavity with the RPPM being used as one of the cavity mirrors.)

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.