Menlo Systems frequency comb helps analyze combined light from four telescopes in the VLT

For the first time, the light impinging on the four main astronomical telescopes that make up the Very Large Telescope (VLT) run by the European Southern Observatory (ESO), has been successfully combined in a single spectrograph. The analysis of the starlight is improved by the AstroComb developed by Menlo Systems (Munich-Martinsried, Germany).

Up on the Cerro Paranal in Chile, ESO engineers and astrophysicists have succeeded in combining the light collected by each of the Observatory's four main telescopes from an object in the farther reaches of the Universe, and directing it into the newly developed ESPRESSO spectrograph for analysis. In effect, the new ability to merge the light from all four of the VLT's 8.2-m mirrors into a single image makes the VLT into the largest optical telescope in the world, in terms of the area of its light-collecting surface.

Menlo Systems’ contribution to this engineering feat is the AstroComb, an optical frequency comb designed specifically for use in astronomy. Together with Prof. John Hall, Prof. Theodor Hänsch, Director of the Max Planck Institute for Quantum Optics and the founder of Menlo Systems, received the Nobel Prize for Physics in 2005 for the invention of the frequency comb.

A frequency comb is a collection of tens of thousands of equidistantly spaced laser lines. Every one of these lines is made up of light of a known frequency, defined in respect to a basic frequency standard, such as an atomic clock or the GPS. As a result, frequency combs can be used to measure single frequencies with extremely high accuracy.

Frequency comb helps determine spectral absorption line frequencies

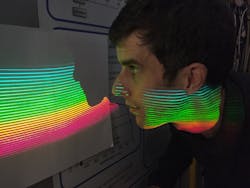

For the calibration of the new spectrograph at ESO, the frequency comb is generated and fed into the ESPRESSO instrument in parallel with the collected starlight. Both the starlight and the frequency comb are then separated into their spectral components by passage through a large diffraction grating and projected onto a CCD imaging sensor. This reveals the individual teeth of the comb, which can then be used like a ruler to assign precise frequencies to the starlight's spectral absorption lines.

Astrophysicists plan to use the ESPRESSO spectrograph to search for and characterize Earth-like exoplanets. With the AstroComb, they are now in a position to detect minimal shifts in the spectral lines of stars. Dynamic changes of this sort can disclose whether or not a given star actually hosts planets, and they can be used to determine the orbital periods of exoplanets, their distances from their parent star, and their sizes.

Astronomers will also use ESPRESSO to observe quasars. Quasars are the most luminous class of active galactic nuclei, and are powered by enormously massive black holes. In addition, researchers hope to investigate whether or not the constants of nature are in fact constant. All of these quests require observational techniques that combine great precision and sensitivity with extreme robustness to external perturbations. Menlo's AstroComb makes an essential contribution to the achievement of these goals, says the company.

Source: http://www.menlosystems.com/events/news-press-releases/view/2711

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.