NIST demonstrates that lidar images 3D objects through fire and flame

Researchers at the National Institute of Standards and Technology (NIST; Gaithersburg, MD) have used laser detection and ranging (LADAR)—often interchangeable with the term "lidar" meaning light detection and ranging—to image three-dimensional (3D) objects melting in flames. NIST says the method could offer a precise, safe, and compact way to measure structures as they collapse in fires.

RELATED ARTICLE: Narrowband blue illumination and matched optical filter allow seeing through fire

Optical range measurements, already used in manufacturing and other fields, may help overcome practical challenges posed by structural fires, which are too hot to measure with conventional electromechanical sensors mounted on buildings. As described in Optica, the NIST demonstration used a commercial LADAR or lidar system to map distances to objects melting behind flames that produced varying amounts of soot. The experiment measured 3D surfaces with a precision of 30 micrometers or better from 2 m away. This level of precision meets requirements for most structural fire research applications, according to the paper.

The NIST demonstration focused on pieces of chocolate and a plastic toy. "We needed something that doesn't melt too fast or too slow but you still see an effect," project leader Esther Baumann explained.

In the 3D mapping system, a laser sweeps continuously across a band of optical frequencies. The initial laser output is combined with the reflected light from the target. The resulting "beat" signals are detected, and this voltage is then analyzed by digital signal processing to generate time-delay data, equivalent to distance (the difference in frequency between the initial signal and the one received from the target increases with distance).

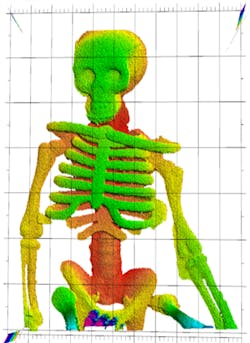

The researchers successfully applied LADAR to measure and map 3D point clouds--points are the voxels constituting an image—even in a turbulent fire environment with strong signal scattering and distortion. For comparison, the team also made videos of the chocolate as it melted and images of a more complex plastic skeleton. The skeleton was barely visible in the conventional video, but the 3D point cloud revealed complex shapes otherwise hidden behind flames—details of the ribcage and hips.

The researchers determined that the LADAR system was fast enough to overcome signal distortions, and that deflections of the laser beam due to the flames could be accommodated by averaging the signals over time, to retain high precision.

The initial experiments were conducted with flames just 50 mm wide on lab burners at the University of Colorado Boulder. The preliminary results suggest that the LADAR technique could be applied to larger objects and fires. The NIST team now plans to scale up the experiment, first to make 3D images of objects through flames about 1 m wide, and if that works, to make quantitative observations of larger structural fires.

SOURCE: NIST; https://www.nist.gov/news-events/news/2018/08/nist-shows-laser-ranging-can-see-3d-objects-melting-fires

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.