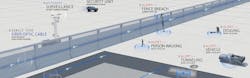

A concrete or steel wall along the southern border of the U.S. is not impenetrable; daily news programs show how concrete walls are burrowed under or driven over with car carriers and hydraulic ramps, while steel walls are breached with grappling hooks and inexpensive metal saws. And while a fiber-optic fence is also vulnerable to a physical cut, it can be discretely buried or placed along existing infrastructure, and (unlike concrete or steel) can fundamentally detect the location of a cut with high accuracy so that border patrol agents can be dispatched to understand the breach and apprehend the humans (easily distinguished from animals) crossing over the fence.

Cheaper to implement than a wall, easier to physically hide, and allowing the natural passage of territorial animals, a fiber-optic border fence also makes funding available for more effective border assets—such as buying drones and installing cameras to put eyes on a fence breach, employing more border patrol agents to apprehend illegal immigrants once detected, hiring more customs attorneys to expedite the legal admission of immigrants into the U.S. that are seeking agricultural jobs or asylum, and concentrating border security funding on better technology at border crossings to inspect vehicles for drugs/nuclear materials and to reduce long wait times for visa-carrying Mexicans or U.S. tourists visiting Mexico.

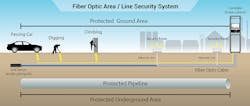

More than a dozen companies manufacture distributed fiber-optic sensing systems that include a light source and a fiber-optic cable that may or may not contain embedded fiber Bragg gratings (FBGs) that reflect light from the source and send it back to the headend equipment to a sensitive detector. Some systems operate in transmissive mode wherein the signal is received by a processor at the far end for analysis and rely on Rayleigh scattering signatures rather than FBG reflections to obtain acoustic disturbance information. Regardless of the technology used, these systems are so sensitive to pressure, temperature, strain, and vibration that in addition to detecting human footsteps, they are also deployed for structural monitoring of bridges, rails and pipelines, aircraft, and can even monitor seismic activity.

For intrusion detection, QinetiQ company OptaSense (Hampshire, England) uses a distributed acoustic sensing setup that analyzes the Rayleigh scattering from a standard single-mode telecommunications fiber (or any existing installed fiber) using an interferometric optical time-domain reflector (OTDR) configuration. The strain signature of a fiber-optic cable around 50 km long can be deconvolved to detect movement at distances of around 10 m from the fiber with a 1 m accuracy.Senstar (Ottawa, ON, Canada) FiberPatrol Buried systems can monitor 80 km of ground perimeters, detecting multiple intrusions (people, vehicles, tunneling) from 5 to 20 m away with an accuracy of ± 5 m using coherent OTDR technology.

Bandweaver (Guildford, England) Perimeter Intrusion Detection Systems (PIDS) pinpoint the location of an intrusion event within 5 m along 5 to 100 km distances, depending on the application. Bandweaver's COTDR detection scheme uses a laser source with a variable pulse duration; for example, a 100 ns pulse can detect an acoustic event with a 10 m detection resolution. While a longer pulse length increases the reflected light level and enables longer-range sensing, spatial resolution suffers. Variable pulse parameters allow the user to customize the system for different applications.Having worked on fiber-optic sensing systems a good part of my career, I was surprised to see just how many companies are in the PIDS game.

Even at a price of roughly $500,000 for a typical 50 km ($10/m) fiber-optic fence (actual pricing is very hard to find), the system pricing would be a dramatic improvement over the U.S. Department of Homeland Security estimate of $21.6 billion for 1250 miles ($10,800/m) of concrete or steel fencing. And when I say "a dramatic improvement"—I mean DRAMATIC: costing a factor of 1000 less than a physical border wall, a fiber-optic fence is a much better alternative. Is there any reason why Congress should buckle under shutdown pressure and have taxpayers foot the bill for an ancient, traditional border-security solution? Let's put the photonics industry to work and build a contemporary, smart fiber-optic wall instead.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.