Ultraviolet light controls and organizes particles suspended in a fluid (with video)

A new, simple and inexpensive method that uses ultraviolet light to control particle motion and assembly within liquids could improve drug delivery, chemical sensors, and fluid pumps. The method encourages particles--from plastic microbeads, to bacterial spores, to pollutants--to gather and organize at a specific location within a liquid and, if desired, to move to new locations. A paper describing the new method appears in the journal Angewandte Chemie.

"Many applications related to sensors, drug delivery, and nanotechnology require the precise control of the flow of fluids," said Ayusman Sen, distinguished professor of chemistry at The Pennsylvania State University (Penn State; University Park, PA) and senior author of the paper. "Researchers have developed a number of strategies to do so, including nanomotors and fluid pumps, but prior to this study we did not have an easy way to gather particles at a particular location so that they can perform a useful function and then move them to a new location so they can perform the function again. Say for example you want to build a sensor to detect particles of a pollutant, or bacterial spores in a water sample," said Sen. "With this new method, we can simply add nanoparticles of gold or titanium dioxide and shine a light to encourage the pollutant particles or spores to gather. By concentrating them in one spot, they become easier to detect. And because light is so easy to manipulate, we have a high degree of control."

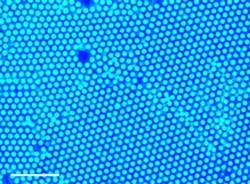

The new method first involves adding a small amount of titanium dioxide or gold nanoparticles to a liquid, like water, that also contains larger particles of interest, like pollutants or beads carrying a payload. Shining a light at a specific point in the liquid heats up the tiny metal nanoparticles, and the heat is then transferred to the fluid. The warmer liquid then rises at the point of light--just as warm air rises in a chilly room--and cooler water rushes in to fill the space that the warm water just left, bringing the larger particles with it. Changing the intensity of the light or the amount of titanium dioxide or gold particles alters how quickly this process occurs.

See the video below for a demonstration:

When the light is removed, the larger particles randomly diffuse through the liquid. But if the light is instead relocated, the larger particles move toward the new point of light, mostly maintaining their structure as they move. This dynamic assembly, disassembly and movement of organized particles may have important implications for sensing and drug delivery.

Although most efficient when gold nanoparticles are used, this method also works with titanium dioxide, an inexpensive and harmless nanoparticle used in cosmetics and as a food additive.

Particles can assemble using this method in hexadecane, which suggests they may be able to apply this technique in, for example, biological fluids.

Members of the research team at the University of Pittsburgh, led by Anna Balazs, used mathematical models to describe the dynamics of the system. In addition to describing how particles move in the system, the models confirm that only a minor change in temperature--less than a degree Celsius--from the ultraviolet light is required to induce the fluid flow. The research team is currently testing the limits of this method, for example if particles can move uphill toward the light source or if the method can be used to sort particles by size.

A fluid pump that relies on this method could potentially replace the bulky and more expensive traditional pumps that require a power source or that rely on magnetics or mechanical movement to function.

In addition to Sen, Tansi and Balazs, the research team includes Matthew Peris at Penn State and Oleg Shklyaev at the University of Pittsburgh. This work was funded by the National Science Foundation.

SOURCE: Penn State; https://news.psu.edu/story/554949/2019/01/22/research/new-method-uses-ultraviolet-light-control-fluid-flow-and-organize

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.