An optical curiosity called the Alvarez lens has been transformed into a practical device by researchers at Lawrence Livermore National Laboratory (LLNL; Livermore, CA). As originally conceived more than 30 years ago, the Alvarez lens contains two transmissive refractive plates, each having a plano surface and a surface shaped in a two-dimensional cubic profile. The two cubic surfaces are made to be the inverse of each other, so that when both plates are placed with their vertices on the optical axis, the induced phase variations cancel out.

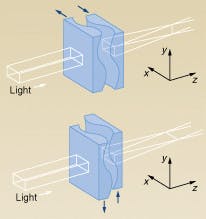

However, if the two plates undergo a relative lateral translation, a phase variation is induced that is the differential of the cubic surface profiles, resulting in a quadratic phase profile—or, in other words, optical power. Relative movements in the x or y direction induce cylindrical power independently in orthogonal directions. Combined movements can produce circular, elliptical, or cylindrical phase profiles.

The refractive Alvarez lens remains largely impractical because its cubic surfaces are so difficult to fabricate. For this reason, the LLNL researchers built a diffractive version, using standard photolithographic techniques (see figure). The resulting pair of fused-silica phase plates has 16-level surface-relief profiles, an operational aperture of 40 × 80 mm, and a longitudinal spacing of 10 mm. Computed diffraction efficiency of each plate is >95%. Operating at 600 nm, the lens will be used to correct pump-induced cylindrical thermal aberrations in a high-average-power laser.

At a 633-nm test wavelength, a 20-mm relative shift of the plates in the y direction produces a y-quadratic phase profile having a power of 2.95 waves. Because the application requires larger power correction for one axis than the other, the cubic profiles of the plates are designed so that a relative displacement along the x axis has a fourfold greater effect than the same displacement along the y axis.

For more general use, the diffractive Alvarez lens could be designed to produce a larger quadratic phase profile for a given relative displacement. Ian Barton, a physicist at LLNL, notes that the phase steps on the fabricated plates are on the order of 100 µm in size—two orders of magnitude larger than the feature size routinely produced at LLNL and elsewhere for other diffractive optics. As the density of the phase features goes up, the effect of the plates gets stronger; thus, a denser diffractive Alvarez lens would have a much higher sensitivity to relative lateral displacement. In addition, such a lens can be made so that relative x and y displacements have effects of equal magnitude.

The researchers are already using the device for intracavity aberration correction. "We have been using the lens in conjunction with a deformable mirror, so that the diffractive optic corrects for the slowly varying, larger-amplitude aberrations in the system, leaving the deformable mirror to correct for the residual aberrations at a faster time scale," says Barton. He notes that the required response time of the Alvarez lens for the LLNL application is on the order of a few seconds.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.