ANNA-LENA SAHLBERG, ZHONGSHAN LI, LASSE HØGSTEDT, PETER TIDEMAND-LICHTENBERG, and JEPPE SEIDELIN DAM

Laser techniques have been widely applied to combustion diagnostics in the last few decades. Nonintrusive measurements with high temporal resolution, spatial resolution, and species selectivity make it possible to visualize flame temperatures and concentrations of minor intermediate species that only exist for a very short time in the flame front.

Coherent, nonlinear laser techniques are especially suitable for high-sensitivity detection of molecules in low concentrations; consequently, high-power pulsed lasers and sensitive detectors are essential ingredients for coherent laser techniques.

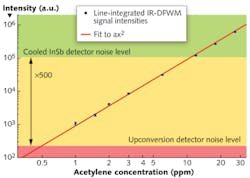

Our team at Lund University and DTU Fotonik has developed an application of infrared (IR) degenerate four-wave mixing in combination with a new, sensitive IR detector that uses upconversion of mid-IR light to near-IR wavelengths in order to make use of the more sensitive detectors available at these wavelengths. This new detector can increase the detection sensitivity of the chemical species acetylene, for example, by more than 500 times, enabling sub-part-per-million detection limits in combustion diagnostics in the mid-IR region. In addition, this upconversion detection principle extends the functionality of traditional detection schemes by providing image information of gas species concentration.

Measuring combustion gases

Today's dominant energy source is combustion of fuels, both for transportation and electricity generation. Despite recent developments in renewable sources like wind and solar energy, combustion will remain important in the foreseeable future. While progress has been made toward the use of biomass and other renewable carbon-dioxide-neutral sources for combustion, the process of adapting engines and gas turbines for different fuels is complex; biomass generally contains different substances like chlorine (Cl), potassium (K), and sulfur (S) that transform into harmful pollutants during combustion. To improve the efficiency of existing combustion engines, as well as optimize new fuels and engines to reduce pollutant emissions, a detailed understanding of the reactions taking place during combustion is essential.

In recent decades, the development of laser diagnostics for combustion research has enabled a deeper understanding of the combustion process. Many molecular species important for combustion—such as water (H2O), carbon dioxide (CO2), methane (CH4), acetylene (C2H2), chloromethane (CH3Cl), carbonyl sulfide (OCS), and hydrogen sulfide (H2S)—that cannot be studied with conventional ultraviolet (UV) or visible lasers (that lack spectral transitions for these species) have strong molecular vibration transitions in the mid-IR spectral region around 2–4 μm.

However, mid-IR spectroscopy for combustion gases is limited by the low sensitivity of available detectors in this region, as well as the large background noise from IR radiation in the high-temperature areas within a combustion flame.

The best available IR detectors today are cryogenically cooled photovoltaic indium antimonide (InSb) detectors that need to be cooled with liquid nitrogen to reduce noise. Even if these detectors are placed well away from the combustion flame, the background IR light from all objects at room temperature severely limits detection signal-to-noise ratio.

Coherent laser techniques

In a coherent nonlinear laser technique, the signal is generated as a laser-like beam that can be detected in the far field away from the flame, significantly reducing background radiation. Infrared degenerate four-wave mixing (IR-DFWM) is a sensitive coherent laser technique that has high potential for sensitive, nonintrusive measurements in combustion situations.

In IR-DFWM, three high-power laser beams are crossed in the measurement volume.1 When the molecules absorb the laser radiation, the interference pattern formed in the crossing region of two of the beams generates a grating of alternately populated excited and ground states of the interrogated molecules. The third beam, called the probe beam, is scattered off this grating and directed to the detector. The wavelength at which absorption occurs indicates which species is present in the measurement volume and the intensity of the signal beam is used as a measure of the concentrations of the species.

To detect the mid-IR signal photons, a cryogenic InSb detector is typically used. However, an upconversion-based detector working at room temperature can significantly improve detection sensitivity and add imaging functionality.

Upconversion

The core principle of an upconversion detector is the transformation of the signal photons from the low-energy mid-IR regime to the higher-energy visible or near-IR regime. This process takes place in a nonlinear crystal and essentially consists of adding the energy of two photons to generate a new photon with a higher energy. The energy sum corresponds to the sum of the frequencies; however, sum frequency generation (SFG) is only possible if the momentum of the participating photons is conserved via phase matching.

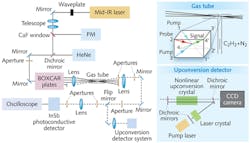

The momentum of a photon depends on the direction of propagation and the refractive index of the media through which it travels. For this reason the upconversion detector is sensitive to both the propagation direction and the wavelength of the incoming signal. When the momentum of the photons is conserved, the process is phase matched, and the field will add up coherently throughout the crystal to form an accumulated signal output at the new wavelength. For our experiments, a periodically poled lithium niobate crystal is used. The phase-match restriction is an advantage in combustion analysis as the accepted bandwidth is limited to a few nanometers and thus blocks most of the thermal background. The upconversion detector is made particularly efficient by exploiting a highly resonant system where the nonlinear crystal is placed inside a laser cavity (see Fig. 1). For this configuration, we have reported upconversion of incoherent images with a conversion quantum efficiency of 20%.2

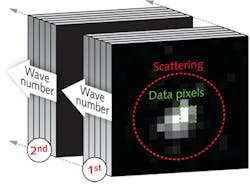

To make a light-tight, low-noise system that is portable without need for realignment, the laser cavity is implemented in a compact black-anodized aluminum box. Because the IR-DFWM setup demands sensitive measurement of the signal beam, the upconverted light from the nonlinear crystal in the laser cavity is focused onto an electron-multiplying charge-coupled device (EMCCD) chip with near-single-photon sensitivity, and one frame is saved for each IR pulse. As the wavelength of the coherent mid-IR light source is swept, the spectrum is built up point by point, and one wavelength in the spectrum represents the sum of the selected data pixels in an image (see Fig. 2).While the CCD camera could in principle be replaced by a sensitive point detector, the CCD image information is helpful in analyzing the noise in the system. Our first analysis of the noise as a function of the wavelength sweep indicated a periodical change in the noise pattern; consequently, we realized that the noise was the result of scattering from various surfaces in the system. This helped us optimize the system and reduce the overall noise significantly both for the upconversion and the conventional detector.

Furthermore, the image detector allows for discrimination of noise sources giving false signals outside the area of the real signal. Thus, by selectively choosing the pixels with best signal and least scattered light, a significant improvement in signal-to-noise ratio is achieved.

In spite of these efforts, the dominant noise source in the system when using the upconversion detector was found to be scattered light. Hence, reducing the levels of scattered light would result in even lower detection levels for the system.

Efficient signal generation

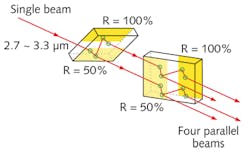

For efficient signal generation, the beams crossing in the IR-DFWM setup must be aligned at exact angles to be phase matched (see Fig. 3). To address the problem of aligning three invisible beams at exactly the right angle to each other (and finding the equally invisible signal beam afterward), we developed a set of reflective calcium fluoride (CaF2) glass plates with special coatings (called BOXCAR plates) specially designed for infrared wavelengths.These plates can be used to split a single laser beam into four parallel laser beams of equal intensities (see Fig. 3). Three of these beams can then be crossed using a CaF2 lens, automatically fulfilling the phase-match condition of the IR-DFWM process. As another benefit, the fourth beam follows the signal beam path, facilitating alignment of the signal to the detector.

The IR-DFWM laser technique is ideal for the measurement of acetylene. Formed in intermediate reactions during combustion of other fuels, acetylene also plays an important role in soot formation as a soot precursor and, thus, it is essential to have an in situ nonintrusive measurement technique to investigate how it is formed in flames. With strong absorption lines near 3.1 μm, sensitivities down to 35 ppm have been demonstrated for room-temperature gas flows of acetylene diluted with nitrogen. Using the spatial resolution of the upconversion system for improved spatial filtering and improved signal-to-noise ratio, a detection level down to 1 ppm is possible (see Fig. 4).3With the upconversion imaging detector, there is potential for improving the IR-DFWM technique for combustion detection to part-per-billion concentration limits, enabling the study of early reactions of soot forming in flames. There are also exciting possibilities for using the imaging properties of the upconversion detector to extend the IR-DFWM technique to two-dimensional measurements for turbulent combustion situations (engines or gas turbines) where species concentration and temperature vary dramatically during the combustion cycle. This makes an instantaneous map of the flame zone necessary for a complete understanding of the combustion process.

References

1. Z. W. Sun et al., Appl. Phys. B 98, 593–600 (2010).

2. J. S. Dam, P. Tidemand-Lichtenberg, and C. Pedersen, Nat. Photon. 6, 11, 788–793 (2012).

3. L. Høgstedt et al., Opt. Lett. 39, 18, 5321–5324 (2014).

Anna-Lena Sahlberg is a PhD student and Zhongshan Li is a senior lecturer at the Division of Combustion Physics, Lund University, Lund, Sweden; http://www.lunduniversity.lu.sw. Lasse Høgstedt is a PhD student, Peter Tidemand-Lichtenberg is an associate professor, and Jeppe Seidelin Dam is a senior researcher at the Department of Photonics Engineering at the Technical University of Denmark (DTU Fotonik), Roskilde, Denmark; email: [email protected]; www.forbrf.lth.se.