Spectroscopy: CVD diamond attenuated-total-reflection prisms benefit FTIR spectroscopy

HARPREET DHILLON, HENK DE WIT, and JOE DODSON

Fourier-transform infrared (FTIR) spectroscopy is increasingly being used for analysis of chemicals and materials across academia, as well as in industries that include pharmaceuticals, chemicals, food and beverage, and life sciences. This trend is driven by growing concerns over the safety of food and beverages, and the need for stringent quality control of pharmaceuticals and their ingredients. Manufacturing industries have also seen a recent surge in the use of IR spectroscopy to implement quality standards and introduce novel solutions to reduce manufacturing costs by reducing scrap material, additional rework, and inventory cost.

Diamond has long been recognized as an ideal material for use as an attenuated total reflection (ATR) element in IR spectroscopy, and was first put into practice using natural diamonds. Diamond's broad range of transmission, high refractive index, and robustness and durability compared with traditional materials bring a versatile combination of properties to lab-based and online spectroscopy tools.1

Until recently, the use of IR spectroscopy techniques has been hindered by the high initial setup investment required, along with maintenance costs and the need for skilled personnel to operate these systems. In addition, the shortage of natural diamonds of consistently high quality and required size and characteristics for use in industrial applications placed a prohibitive cost on the development of IR spectrometers to their full potential. Over the last few years, new approaches that exploit the extreme properties of synthetic optical-grade chemical-vapor-deposition (CVD) diamond have resulted in cost-effective and robust diamond ATR elements in IR spectroscopy.

Continuous development of synthetic single-crystal (SC) diamond has enabled many new optical applications, as the availability of large volumes at high quality have dramatically improved over the last decade.2,3 New shapes, like cones, hemispheres, and large prisms, have now come within reach for general spectroscopy applications. This has led to the introduction of new spectroscopy tools driving the change from lab-based equipment to in-line spectroscopy for real-time measurements.

CVD diamond—an ATR accessory

Diamond has long been known to have exceptional properties, largely resulting from the symmetry of the cubic lattice made of light carbon atoms connected by extremely strong bonds.4 Historically, diamond has been exploited mainly for its great hardness in mechanical applications—however, it is also used in applications where its sensing, thermal, or semiconducting properties are beneficial.5 From an optical perspective, diamond is particularly useful in ATR accessories compared to other IR materials because it is extremely hard and scratch-resistant, making it durable and easy to clean.

CVD SC diamond has the widest transmission spectrum (from 220 nm to >50 μm) of any optical material, enabling ATR accessories capable of analyzing a host of materials covering a wide range of refractive indices.6 Measurement sensitivity, analysis range, and efficiency are improved by using a single diamond prism component.

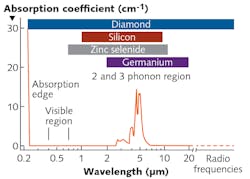

The absorption spectrum of optical-grade SC CVD diamond is shown in Fig. 1. The only region of spectral absorption in this grade of diamond is the multiphonon intrinsic absorption observed between 2.5 and 7 μm. This broad transmission spectrum allows spectrometer manufacturers to simplify optical systems while maintaining broadband capabilities.

Diamond is chemically and biologically inert, enabling the analysis of strong acidic or caustic materials (pH 0 to pH 14) in harsh environments where other materials, such as zinc selenide and geranium, would degrade—even if it becomes damaged, diamond does not become toxic. Diamond's strength, combined with its stiffness, allows high compressive forces to be used, ensuring that even hard and stiff solids (including powders) will be in intimate contact with the prism without distortion.

CVD diamond ATR FTIR

Attenuated-total-reflection accessories simplify IR spectroscopy because the sample being analyzed only needs to be placed on one surface—the sample no longer needs to be clamped and spread between two windows, as with traditional transmission measurements. ATR accessories open up quicker analyses through reduced sample preparation time and easy measurement of liquids, pastes, or solids. Because an ATR measurement only uses the top few microns at the surface of the sample to produce a spectrum, it is even possible to measure opaque materials.

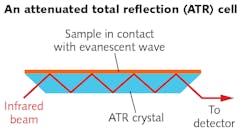

In ATR-based spectroscopy, a beam of IR light is passed through one side of an ATR crystal in such a way that it reflects off an internal surface of the ATR crystal in contact with a sample to be analyzed (see Fig. 2). This reflection forms an evanescent wave that extends into the sample. The penetration depth into the sample is typically between 0.5 and 2 μm, with the exact value being determined by the wavelength of light, the angle of incidence, and the indices of refraction for the ATR crystal and the sample being examined. The number of reflections may be varied by varying the angle of incidence and the geometry of the ATR crystal. Having been spectrally influenced by the sample's absorption, the IR beam is then collected by a detector after it exits the opposite end of the ATR crystal.Developments in CVD diamond

Two recent developments in Element Six's manufacture of synthetic optical-grade SC CVD diamond have advanced its applicability for ATR prisms. First, improvements in understanding the synthesis process and careful control of impurities have led to a consistent supply of high-quality synthetic diamonds that can be made on a production scale.

Secondly, improved processing capability has led to the fabrication of high-performance ATR prisms in a range of geometries and sizes with a scaife-polished finish (a scaife is a type of diamond-polishing wheel).

ATR crystal geometries can allow for single or multiple reflections. An example of a single-reflection ATR prism is shown in Fig. 3. Here, the prism is a 45° rectangular prism, with the incoming light coming in through one of the angled faces. The beam hits the interaction interface at a 45° angle and then leaves through the other 45° face to be received by the detector.The geometry of an ATR crystal will depend on the type of spectrometer and nature of the sample to be analyzed. Typical ATR crystal geometries include prisms, truncated prisms, chamfered rectangular blocks, chamfered cylinders, and similar variations. In the example 45° rectangular prism, compounds with a refractive index up to 1.69 can be analyzed. If more sensitivity is required, alternate geometries can be chosen to optimize the analysis of lower-concentration features.

Common elements of these ATR geometries include a flat working surface that is pressed against the sample to be analyzed, and angled or chamfered sides. The angled sides are normally coated with an antireflection coating, providing high-transmission entry and exit surfaces for the IR analysis beam.

Mounting optical-grade CVD diamond components

Diamond prisms are easier to use and integrate into other equipment once they have been mounted. Typical mount materials include Hastelloy, stainless steel, molybdenum, and tungsten carbide, with the design chosen to match the required application.

The more-common mount geometries include disc-shaped mounts such as those shown in Fig. 4, while more-complex arrangements have included an ATR prism mounted on the tip of a probe.These mounted designs can be tuned to serve at a variety of operational temperatures (for example, 250°, 350°, or 500°C) and environments by selecting the appropriate alloy for the material that is used to braze the diamond prism into the mount. In addition to temperature stability, the braze material must be chemically inert to ensure the integrity of the bond under harsh environmental exposure. Most commonly used are alloys of gold with tin, germanium, or tantalum. Where overall chemical stability is important, the mount can be gold-plated to cover the exposed surfaces.

Major suppliers of FTIR equipment have developed small-footprint, miniaturized spectrometers and modules based on optical-grade CVD diamond components. They have brought IR spectroscopy from the research lab to the production line, where operators can take all measurements using integrated software to ensure reproducible production of high-quality products. As a result, quality control has developed from time-consuming sampling to continuous in-line systems.

REFERENCES

1. T. P. Mollart et al., Semiconductor Sci. Technol., 18, S117–S124 (2003).

2. A. Bennett, Optik and Photonik, 9, 4 (2014).

3. M. Boulet-Audet et al., J. Phys. Chem. B, 114, 24, 8255 (2010).

4. A. Feldman, Mater. Sci. Monogr., 73, 181–188 (1991).

5. R. S. Balmer et al., J. Phys. Condens. Matter, 21, 36, 364221 (2009).

6. P. J. Dean, Phys. Rev., 139, 588 (1965).

Harpreet Dhillon is a senior research scientist, Henk De Wit is business manager – optics, and Joe Dodson is a product application engineer, all at Element Six, Ascot, Berkshire, England; e-mail: [email protected]; www.e6.com.