Microresonator optical gyroscope operates via Brillouin laser cascade

Laser gyroscopes lie at the heart of many precision commercial and military inertial-navigation systems. Because conventional laser gyroscopes, which are based on either a fiber-optic coil or a free-space ring cavity, are bulky, attempts have been made to produce micro-optical laser gyroscopes. Now, researchers at the California Institute of Technology (Caltech; Pasadena, CA) have developed a chip-based laser gyroscope that uses counterpropagating Brillouin lasers and measures rotation as a Sagnac-induced frequency shift. The first prototype has demonstrated a rotation-rate measurement 40 times greater than that of previous micro-optical laser gyroscopes.

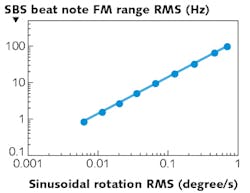

An 18-mm-diameter high-Q disk microresonator made of silica on a silicon chip is excited by a single laser pump wave, which induces a first Stokes wave that, at high-enough power, pumps a second Brillouin Stokes wave that propagates in the opposite direction, inducing another Stokes wave, and so on, resulting in a Brillouin laser cascade. The researchers tested the gyro by applying a sinusoidal rotation with an angular amplitude of 0.14°. A sensitivity of 15 deg/h/(Hz)0.5 and a minimum root-mean-squared rotation rate of 6.3 × 10-3 deg/s (or 22 deg/h) were measured. Narrowing the linewidth of the Brillouin lasers should improve the gyro's sensitivity further. Reference: J. Li et al., Optica (2017); https://doi.org/10.1364/optica.4.000346.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.