Microdisplays: Thin quantum wells improve brightness and color in microLED microdisplays

Microdisplays used in defense, aerospace, and industrial applications are typically based on reflective, transmissive, or transreflective architectures such as liquid-crystal on silicon (LCOS) or digital light processing (DLP). Virtual reality (VR), augmented reality (AR), and other commercial applications, on the other hand, tend to use active-matrix organic light-emitting diode (AMOLED) technology, usually generating white light with red/green/blue (RGB) colors obtained through color filters.

These options are not particularly efficient-consuming too much power for extended, untethered mobile use and suffering from low brightness, with generally poor color gamut and saturation. Images projected against bright, daylight backgrounds tend to have insufficient contrast to be useful, and these issues are exacerbated as pixel sizes shrink with next-generation microdisplays.

An emerging alternative microdisplay using microLED technology can be 1000X intrinsically brighter than competing micro-OLED technology. However, its gallium nitride/indium gallium nitride (GaN/InGaN) composition emits in the monochrome blue spectrum around 450 nm, obviating the need for RGB conversion. But traditional means of downconversion, such as the phosphors used in solid-state lighting (SSL), become impractical as pixel sizes shrink. For adequate blue-light absorption, they would need to be 100–1000X thicker to match a comparable direct-bandgap semiconductor, while quantum dot (QD) options need not be as thick, but cannot handle the high optical-flux density of microLED emitters.

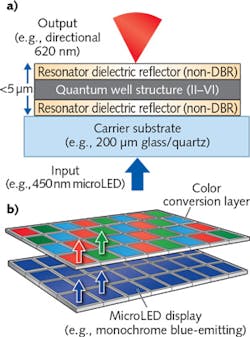

Recognizing these insufficiencies, VerLASE Technologies (Bridgewater, NJ) has developed a quantum-well (QW) technology called Chromover that integrates a proprietary resonator structure with QW layers in a semiconductor stack <5 μm thick that allows near-full absorption of the intrinsic blue pump light from the microLED while simultaneously meeting resonance conditions for a desired output. It enables high-efficiency color conversion at the pixel level into red and green (see figure).1

Thin quantum wells

The Chromover structure is made using conventional wafer-scale processes and is materials-agnostic: the QWs and resonator layers can be made of standard II-VI materials for QDs such as zinc selenide variants (ZnCdSe/ZnSe), or from III-V materials or other materials for ultraviolet or near-infrared applications. Furthermore, the resonator structure can be designed for highly directional output, confining light within a cone angle or, if pumped with laser input, even designed to lase as an optically pumped vertical-cavity surface-emitting laser (VCSEL).

VerLASE works with microLED manufacturers to customize its Chromover design for a specific microLED microdisplay, engineering the layers for maximum input light to the color-converting stack, high extraction efficiency, and interpixel crosstalk mitigation. The interface between the microLED and color-conversion layer must also be carefully designed for high conversion efficiency.

"We know of no other downconversion technology that is also highly directional, putting photons of the right color where they are the most effective," says VerLASE CTO Ajay Jain. "To superimpose an image onto a user's field of view, next-generation AR eyewear being developed by leading players uses sophisticated diffractive or holographic waveguides that are sensitive to input light angles and spectral composition, and further increase the need for brightness—all of which Chromover technology uniquely addresses."

REFERENCE

1 See https://goo.gl/WvLqEW.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.