Tunable Lasers: Carbon enables record wavelength tuning for 2 μm ultrafast lasers

Mode-locked lasers are key enabling tools for a number of scientific and engineering fields, such as fiber-optic communications, metrology, biological imaging, and solid-state physics research. Of the many figures-of-merit for ultrafast fiber lasers (peak power, pulse energy, and pulse duration), wavelength tunability is a highly desirable one, as it enables a great degree of application flexibility for end users in frequency comb generation, molecular absorption line detection, and time-resolved spectroscopy.

Because of the limited bandwidth of common gain materials and saturable absorbers, however, mode-locked lasers usually have a rather narrow tuning range. An exception is Ti:sapphire lasers, a current workhorse for ultrafast science, although these lasers typically operate at a wavelength of 1 μm or below. To access wavelength tuning capabilities beyond 1 μm, nonlinear wavelength-conversion devices such as optical parametric oscillators (OPOs) or amplifiers (OPAs) are used as standard extensions to commercial Ti:sapphire lasers, but the relatively large footprint and cumbersome requirements on maintenance have significantly limited their applicability for field-deployable applications.

Carbon-based tunability

Gain materials with broad emission bandwidth around 2 μm have matured quickly over the past decade. And now, researchers at Nanjing University (Nanjing, China), who recently demonstrated lasers operating in the midwave-infrared (3-6 μm) using nonlinear Dirac semimetals, are now using carbon-based nanomaterials to enable record tuning range from compact and low-cost 2 μm laser oscillators.1 Specifically, the carbon nanotube (CNT)-based thulium/holmium (Tm/Ho) fiber laser developed by the researchers is continuously tunable across 200 nm from 1860 to 2060 nm, which is, to the best of their knowledge, the widest tuning range ever achieved for a passively mode-locked fiber-laser oscillator.

"Currently, for people looking for wavelength-tuning solutions in the long-wavelength range, there are simply not many options," says Nanjing University professor Frank Wang. "Carbon materials seem to be a good match to these broadband gain materials at 2 μm. They may just be able to play the key role that the Kerr lens had played for Ti:sapphire lasers decades ago."

The 200 nm tuning range was achieved in a picosecond thulium fiber laser by combining the CNT saturable absorber with a home-built grating mirror. First, CNT films with 20 μm thickness were fabricated using solution processing and Raman spectroscopy. The tube diameter distribution was 1.3 to 1.6 nm, dimensions that exhibit relatively high absorption in the gain region of the Tm3+-doped fiber-helpful for maintaining good modulation depth.

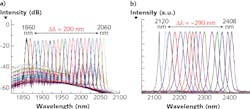

In the experimental setup, the output of a 1560 nm, 10 mW laser diode amplified to 1 W by an erbium-doped fiber amplifier (EDFA) is input via a wavelength-division multiplexer (WDM) to a 2 m length of 0.16 numerical aperture (NA), 9 μm core-diameter Tm/Ho co-doped fiber with wavelength tuning achieved using a fiber collimator and a 600 lines/mm free-space diffraction grating. The CNT saturable absorber at the second arm of the WDM enables the mode-locking process and the 200 nm tuning range with an impressive 60 dB sideband-suppression ratio for the resultant pulses and 1% power deviation over a 36-hour continuous-wave tuning period.

In a separate experiment, graphene was used to demonstrate an even broader, approximately 300 nm tuning range for a chromium:zinc sulfide (Cr:ZnS) solid-state laser, where the output is as short as 200 fs and wavelength selection is achieved using a prism pair (see figure).

"Our preliminary results are quite promising; they suggest that carbon nanomaterials, including carbon nanotubes and graphene, may be the key optical switching materials enabling a new generation of broadly tunable mode-locked fiber lasers in the technologically important 2 μm region," Wang says. "It is quite likely that these carbon-enabled systems will be commercialized, considering the huge advantages in terms of footprint and cost reduction."

REFERENCE

1. Y. Meng et al., Nat. Sci. Rep., 7, 45109 (Mar. 21, 2017).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.