As a manufacturer of both red, green, blue (RGB) laser-based and light-emitting diode (LED)-based displays of all sizes, Christie (Cypress, CA) sheds light on the technical comparison between RGB laser projection and LED modules when used as the light engines for cinema-scale display applications.

Color and contrast

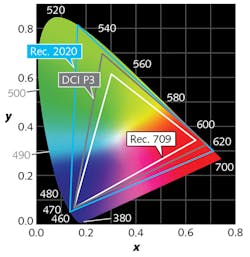

Conventionally, most LEDs are incapable of reaching the wider color-gamut capabilities of RGB projection systems. Although some LED screens for cinema can reproduce Digital Cinema Initiatives (DCI) P3 color gamut, the vast majority of LED screens support little more than the Rec. 709 color standard created for HDTV in the 1990s (see figure).

LEDs inherently have a manufacturing variance in color that requires tightly selective binning and sorting to achieve the red, green, and blue that would be required to meet DCI specifications. This difficulty in maintaining color stability and consistency is a contributor to higher costs, with frequent, targeted replacements needed, whereas RGB lasers maintain steady color output through their full operating lifetime.

Rec. 2020 is commonly referred to as the next-generation color gamut specification. However, it is difficult for lasers to achieve, as it does not provide spectral diversity and also makes image speckle more noticeable as it restricts the frequency of laser-light arrays required to achieve the prescribed gamut. For cinema, a standard that is somewhere in between DCI P3 and Rec. 2020 is preferable to deliver a wider color gamut than is currently available while remaining economically viable.

Visual methods and anomalies

RGB projectors and LED screens display visual data through different methods. A projector reflects RBG laser light off a screen that can be flat or curved and is permeable for audio, whereas LED screens are large, direct-view, emissive, and acoustically reflective displays.

While point-source illumination gives LED screens a slight edge at controlling contrast compared to RGB projection technology, RGB is also making great strides in contrast and dynamic range performance, and the latest RGB-based systems can achieve a 400% improvement in contrast over lamp-based projection systems found in cinemas today.

Densely packed LED screens suited for cinema can cost in excess of $75,000 per square meter and introduce certain visual anomalies not seen with RGB projection. Some LED modules have large gaps between pixels that a viewer can easily perceive depending on viewing distance. While laser projection systems "size to the environment" based on optically adjusting the size of the pixels to match the screen, LED solutions have a problem scaling content to fit the required image size of the environment in which they are installed. As such, an LED display in a cinema would need to be restricted to a certain size (based on pixel dimensions). Scaling an image to be bigger or smaller than this fixed screen size would require high-quality image processing not normally found in LED systems today or various pixel pitch systems based upon screen size requirements, making it more difficult to scale manufacturing and driving up system costs.

In addition, because LED screens are made up of matrices of LEDs, a visible seam between the individual modules can be seen if there is a gap larger than the pixel pitch or if the modules are not in perfect alignment.

Finally, it is more costly to achieve three-dimensional (3D) viewing with LED cinema. Where projectors can use a small polarizer in front of the lens and require 3D movie-goers to wear low-cost passive and light-efficient glasses, LED screens would require an enormous and therefore expensive polarizer in front of the entire screen, or the use of a high-maintenance and more costly active 3D system with complex, more-expensive viewing glasses.

Maintenance, serviceability, and cost

For LED screens, the illumination source replacement requires swapping entire modules. The replacement modules need to match the existing modules in color and brightness, which adversely changes the degradation rate for the screen and complicates scheduled maintenance, as the different modules will age and vary in output over time. Matching new modules to older modules is difficult and costly in even the most expensive solutions used today. Aging LED screens can also have dead pixels or failed pixels stuck in the "on" position that can ruin the viewing experience.

With projectors, the illumination source is switched out as it ages and will quickly be up and running again at original performance specifications.

Christie concludes that, unlike second-generation RGB projectors now available to cinema venues, LED screens of comparable size are not yet at the price point to compete.

REFERENCE

1. See https://goo.gl/9EMx2x and https://goo.gl/kfFkkp.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.