Visible Laser Diodes: How are green laser diodes changing biomedical diagnostics?

PEDRO MUÑOZ

DNA and cell analysis tools have become indispensable in the quest for new medical therapies and life-science research. We are witnessing an evolution of diagnostic tools from bulky, complex, and expensive devices to compact, simpler, and more cost-effective equipment. These changes are creating a revolution in the biomedical industry, thanks to breakthrough advancements in laser diodes and other technologies.

After Osram Opto Semiconductors introduced the first direct green laser diode in 2012, a wave of low-cost diagnostic tools has been developed. For example, Osram’s PLT5 488 nm cyan laser diode is now replacing diode-pumped solid-state (DPSS) lasers in biomedical applications (see Fig. 1). This 488 nm laser diode enables less-complex and more-economical designs because it has a good far-field pattern and tight wavelength tolerance of ±2 nm.

History of lasers in biomedical diagnostics

Typical argon-gas laser lines at 458, 476, 488, 497, 502, 515, and 529 nm are used to excite fluorescent probes. These probes are helpful in biomedical research because they preferentially attach to specific structures of cells or DNA sequences, allowing users to perform tests at both the cellular and molecular level. The fluorescent probes are excited by a light source of a specific wavelength and their localized response is then revealed by a detector. These wavelengths are still among the most requested wavelengths, with 488 nm being one of the most popular.

DPSS lasers have long replaced argon gas lasers as the laser source of choice. DPSS lasers use infrared (IR) laser diodes to pump an active solid-state medium, which emits a laser with very good beam quality, even at high power levels. The laser can be tuned to deliver different wavelengths in a broad range. However, DPSS lasers’ sensitivity to temperature, limited long-term stability, and noise are concerns. Also, DPSS lasers, by design, will always include a complex set of optical components (including nonlinear crystals) that need to be aligned (see Fig. 2). The active components are costly as well, making DPSS lasers both difficult and expensive to manufacture.In comparison, laser diodes are small and easy to modulate (well above 100 MHz) with controlled-current drivers. They offer good single-mode beam quality without the complexity of DPSS lasers, allowing them to be manufactured at a much lower cost.

The main obstacle to replacing DPSS lasers with laser diodes has been the limited availability of desired wavelengths. Even after the development of short-wavelength blue lasers for Blu-ray optical drives and Osram’s 450 nm laser diode, the so-called “green gap” made many wavelengths of the argon-gas laser inaccessible at a laser diode level.

First direct green laser diode

Osram’s direct green laser diode at 520 nm was a major breakthrough because it opened up laser diode technology to argon-gas wavelengths. More recently, Osram introduced a laser diode with a center wavelength selection of 488 nm. The 488 nm wavelength is the most common in life science research applications because there are hundreds of fluorophores specifically tailored to excite at, or very close to, 488 nm.In these biomedical applications, the light of the laser and the fluorescent light from the probes need to follow different optical paths. The different light sources are separated by dichroic optics with small bandpass filters. Therefore, the laser diode needs to have a very well-defined wavelength with small tolerances. Osram offers ±2 nm for this device to ensure a consistent excitation and successful light separation. The wavelength is measured at typical application requirements of either 25 or 60 mW optical output power.

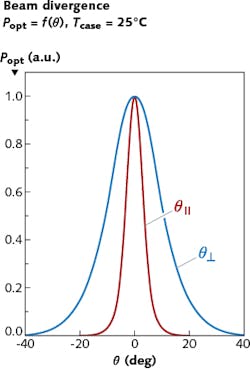

There are challenges when considering laser diodes that need to be addressed. Provided the required wavelength is commercially available, longitudinal and single-mode laser diodes are the logical choice for systems requiring less than 100 mW. The typical beam output of single-mode laser diodes is highly divergent and asymmetrical, but the emitter size is usually smaller than 1 µm, making it relatively easy to collimate the beam with very small optics and couple into a single-mode fiber.

However, an issue that can occur in some laser diodes is the undesired appearance of a ghost side lobe. The side lobe typically accounts for 1–2% of the total light. While this ghost is very faint, it interacts with the optical system and can easily distort measurement, making optical design much more challenging. The ghost side lobe only appears with some lasers, and the strength of the side lobe varies from laser diode to laser diode.

Osram has investigated the causes of these unwanted side lobes and developed a set of manufacturing protocols to correct the issue. Osram’s solution, Brilliant Beam Technology, efficiently suppresses the side lobes at their origin and ensures a dependable far-field beam quality that resembles a perfect Gaussian single mode (see Fig. 3). This technology creates much more reliable laser diode characteristics, even in the large populations. The ultimate benefit is higher yields in production.

Overall, laser diodes are more energy-efficient than DPSS laser systems, making them more suitable for battery-operated, handheld devices. The wall plug efficiency has a direct impact on the diode lifetime because light degradation is greatly influenced by the heat generated within the chip.

Larger efficacy means more light with less heat and therefore longer lifetimes. Blue, cyan, and green single-mode laser diodes already show very long lifetimes (2% or less light loss every 1000 hours). When thermally connected to a heat sink and operated at 60 mW optical output or below, these values can significantly improve.

During operation, there is a power output and wavelength dependency on temperature (~0.3 mW/K, ~0.04 nm/K), which can be regulated with a Peltier element for high precision. This behavior is intrinsic in the semiconductor materials and a very dependable property that does not vary from laser diode to laser diode. Besides, this effect is 10X smaller than the same effect observed in IR and red laser diodes (using AlGaAs for semiconductor instead of InGaAs for 488 nm), and should not pose a major problem.

Laser diode applications in biomedicine

Companies that implement turnkey lasers are challenged by the bare simplicity of the laser diodes themselves. They need to figure out an appropriate driver, implement safety measures for eyesight protection, and calculate and install aligned optics for circular and low-divergence laser beams. Also, the mechanics to ensure sufficient thermal contact and cooling of the laser device can be challenging, especially for applications requiring very high laser stability and low noise.

To understand the potential market impact of the new 488 nm laser diode, consider a recent project by World Star Tech (Markham, ON, Canada), a distributor of Osram laser diodes that has specialized in solving laser application problems. World Star Tech worked with Orflo Technologies (Ketchum, ID) to update the Orflo Moxi GO II cytometer from a 532 nm DPSS laser to a 488 nm laser diode, thus helping to create a new market for cost-effective and portable flow cytometers (see Fig. 4).The Moxi GO II is a combination of Coulter-style cell size determination with simultaneous fluorescence detection. All Orflo particle analyzers use a low-cost, single-use microfluidic flow cell. By leveraging a consumable flow cell, Orflo can remove all of the components typically found in traditional flow cytometers (for example, all of the wet components like wash fluids, tubing, and peristaltic pumps).

Each time a microfluidic flow cell is inserted into the Moxi GO II, the 488 nm laser diode is automatically aligned to a micro-drilled detection zone, thereby helping make the system portable and robust. Inside the microfluidic flow cells, particles (including biological cells) flow one at a time through the detection zone. As each particle transitions the detection zone, it perturbs a constant current electric field, causing a voltage spike that is proportional to the particle volume (also known as the Coulter Principle). Simultaneously, epifluorescence is collected from the cell/particle and the light is sent to a nearby bank of photomultiplier tubes.

All Orflo systems are affordable, compact, battery-powered, and easy to use, and Orflo has placed thousands in research labs around the world. The company plans to continue launching products that leverage these new lasers to help increase the pace of scientific discovery.

The Moxi GO II is just one of the first applications for the 488 nm laser diode, not only in biomedical applications, but also in diagnostic systems for clinics and, eventually, homes.

Another example is the WhisperIT 488 solid-state laser from Pavilion Integration (San Jose, CA), which uses GaN 488 nm laser diodes to enable compact and efficient laser designs for biotechnology instrumentation applications and other markets. The 488 nm laser diodes in free running operation exhibit a range of cavity modes that change with operating power. Mode-hops cause a significant change in the peak wavelength and would render these laser diodes unusable for many applications, but the Whisper technology overcomes these drawbacks and turns 488 nm laser diode light into useful laser light. In addition to stabilizing continuous-wave operation, the same improvements are observed when modulating the laser diode. The combination of the Osram 488 nm laser diode with the PIC WhisperIT technology enables a solution with fast turn-on, power variability, and modulation without the use of a shutter, neutral density filter, or an acousto-optic modulator.

Pedro Muñoz is senior marketing manager of emitters, lasers and sensors at Osram Opto Semiconductors, North America; Sunnyvale, CA; e-mail: [email protected]; www.osram-os.com.