How to choose a laser diode for your application

Laser diodes are the hidden champions of current laser technology—from simple laser pointers to sophisticated quantum communication satellites, laser diodes are everywhere. They offer supreme efficiency, small footprint, and best of all, the price per watt is going down. And they are available in a myriad of different types.

Many people consider using a laser diode—some may think about entirely new systems, while others just want to replace an older gas laser in their product. The problem is the variety of choices, as there are many different laser diodes available and making the right choice may take days for both the engineer and the sales expert as well.

This tutorial will help to answer the most important questions: What is the right laser diode for the application? Which parameters are paramount, and which can be neglected?

The tutorial will ask a set of questions that directs the reader toward a table that can be used to find the right laser diode quickly. This logical process may help anyone, from a PhD student to an experienced engineer, to find a good solution. The logic of this tutorial results from many years spent by the authors consulting with various customers looking for the appropriate laser diode.

Step 1: Turn application requirements into laser parameters

The fields of application are wide—whether it is analytical equipment for life sciences, heavy duty lasers for reconnaissance missions, seed diodes for materials processing systems, or ultra-stable laser diodes for metrological tasks, it’s all about making the right choice for the right laser diode.

To find the right laser diode for your case, you probably start with a set of parameters determined by your application. We will do this here with the help of an example—let’s assume we want to build a decent laser interferometer for surface profiling or velocity measurement.

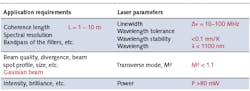

For this device, we need a laser diode with a coherence length of 1 to 10 m, and the interferometric pattern should stay stable through temperature change (<0.1 nm/K). We need a collimated Gaussian beam and the power should be >80 mW. The detector we are using is based on silicon (Si), which works only for wavelengths <1100 nm. The center wavelength itself and polarization are less important in this case. We have no idea about package or pinning at that point.

Table 1 shows you the data we have so far, with pure application requirements listed on the left side and laser parameters on the right side. From the coherence length, we can calculate the linewidth using Δν =c/πL= 9.6–95.5 MHz.

For those new to the field, we should explain the parameters in more detail. Most of the details can be found in Rüdiger Paschottta’s RP Photonics Encyclopedia (see www.rp-photonics.com/encyclopedia), which is an excellent resource for all kinds of background knowledge about photonics.

Coherence length is the distance over which the coherence significantly decays. Actually, it even relates to the temporal coherence length, but for our purpose the definition above is sufficient. For more details and a calculator, you may refer to www.rp-photonics.com/coherence_length. We used the following formula later in this tutorial: Δν =c/πL, where Δν is the bandwidth (or linewidth), c the speed of light, and L the coherence length.

Spectral resolution denotes the relation between the bandwidth (in nanometers) and the wavelength: R= λ/Δλ. In case of a spectrograph or, more generally, of a frequency spectrum, it is a measure of the laser’s ability to resolve features in the electromagnetic spectrum.

If you want to calculate the bandwidth in megahertz (MHz) from a nanometer (nm) value, you may use the Δν= Δλ*c/λ2 formula or an Internet calculator, such as the one at www.photonicsolutions.co.uk/wavelengths, which even offers the conversion into wavenumbers (cm-1) and four other units of bandwidth.

Bandpass. Some sensors for the detection of a laser signal use interference filters to block disturbing ambient light. Thus, the wavelength of the laser source has to be kept within the small transmission range of the filter. For the vendor, that’s important information—but in our example, a limited center wavelength tolerance can be neglected.

Beam quality can be defined in several ways. One is the M2 factor, which says how close a beam is to its ideal Gaussian shape. So, 1.0 denotes a perfect Gaussian beam. Another one is the beam parameter product (BPP), for which we must multiply the beam waist at focus with the far field divergence. For more details, please visit www.rp-photonics.com/beam_quality.

Intensity denotes the laser power in the beam area, preferably the focus. Accordingly, its unit is W/cm2. The question here is what you take as beam area—a detailed discussion can be found at www.rp-photonics.com/optical_intensity.

Beam profile is a name for the intensity distribution in the laser beam. Depending on that distribution, it might be flat-top (rectangular distribution) or Gaussian. A single-mode beam is usually (close to) Gaussian, whereas a multimode beam is usually not Gaussian. It may have a variety of shapes, depending on the number and intensity distribution of the mixed modes.

Brilliance or brightness of a laser source gives a measure for its output power and beam quality in one number. Essentially, it is the laser power divided by the BPP. Therefore, its unit is W/cm2*sr—see more details at www.rp-photonics.com/brightness.

Step 2: Selecting the laser type

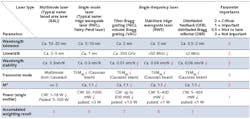

In the second step, we will try to be more specific with the laser type. Here, we face many options. A proper way to get through that is weighing the options and selecting the one with the largest total weight (see Table 2). The gray-shaded fields show the different options that are typically available for single-emitter laser diodes.

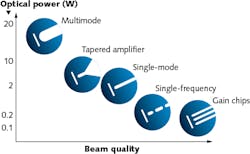

For the sake of clarity, we are focusing on edge-emitter laser diodes only. Other common laser types, including vertical-cavity surface-emitting lasers (VCSELs), bars/stacks, arrays, or quantum-cascade lasers (QCLs), are not subject of our discussion because of significantly deviating characteristics. However, those families can be evaluated each with similar methodology to narrow down a suitable solution. Note that the output power of these edge-emitting laser diodes typically varies in relation to the beam quality delivered by designs (see figure).

To arrive at a decision, we first tag all fields with parameters that suit our application (that is, our example about building a laser interferometer). There is no tag in the row for wavelength tolerance because we did not make any restrictions on that. Accordingly, the weight is zero. For the linewidth, we calculated something between 10 and 100 MHz, so <50 MHz in the stabilized ridge waveguide column sounds reasonable. Since this is a critical parameter, it gets a weight of 2.

We continue tagging in the other rows and give a weight for the importance in the last column as needed for our application. In the last row, we sum up all tags multiplied by their weight. It turns out that the “Single-frequency laser/Stabilized ridge waveguide laser type” column gets the highest weight of 9. Consequently, this is the laser diode type we look for.

You can make this chart even more sophisticated by noting the weight in each cell. This may be clever if the size of one parameter may once be much better than needed (a weight of 0.5 is nice to have) or just within the specifications (2 is critical). You may tweak here if you prefer a cheaper solution on the edge of your parameter space of if you want to be on the safe side for this parameter.

Step 3: Selecting the laser material

The wavelength is often very important for the application, but do you know why a laser from a certain company covers only a particular wavelength range? It’s the material they use that allows or prohibits particular wavelength ranges.

Table 3 gives an overview of specific materials and their wavelength ranges. In our example, the detector is based on Si, which limits our laser emission wavelength to <1100 nm. This means that laser diodes of gallium nitride (GaN) or gallium arsenide (GaAs) could be fine for us. Usually, ultraviolet (UV) solutions are more expensive than laser diodes in the visible (VIS) or near-infrared (NIR), so we tag the VIS-to NIR material.

Step 4: Make your final chart and go searching

Now, we have all parameters needed for the proper selection of a laser diode. Table 4 shows a set of parameters as derived in the previous charts, plus some remaining parameters that we will discuss below:

Operational mode (continuous-wave [CW], pulsed, or modulated). This can have huge impact on the thermal management and, therefore, the package style. For pulsed or pulse-modulated laser diodes with low duty cycle, there might be less waste heat and so the package size can be smaller.

Beam collimation (free-space, with integrated optics, or fiber-pigtailed). This depends strongly on your application. Often, a standardized optical connector interface, such as ferrule connector (FC) or standard connector (SC), is useful.

Packaging. Do I have a planar (for example, PCB or heat sink) or a circular (tube) environment? The first leads to butterfly or flat-pack solutions, and the latter to a TO can. Are there any overall size limitations? Do I need drop-in compatibility with existing solutions? For TO-based packages, the pin configuration must be determined (m-, n-, or p-type) as well as the size (5.6 vs. 9 mm). For 14-pin butterfly packages, telecom and pump pinning must be distinguished.

Pricing. Above all, there is one important rule for the pricing of laser diodes. If your absolute center wavelength is not fixed rigidly, look for commodity lasers. Some of the large providers (for example, Lumentum or Sony) provide certain laser diodes for consumer applications such as game consoles or smartphones. In the industrial area, some popular wavelengths exist, such as 852 or 980 nm for fiber laser pumping or spectroscopy. Those laser diodes are much less expensive than others.

On the other hand, a customized laser diode has the benefit of more safety for serial manufacturing, as you can become a strategic partner of the laser diode supplier and the supplier would not discontinue production without notice. This is important if you move from single devices to batches of up to hundreds or tens of thousands of laser diodes per year—a volume still by far under the radar of mass market vendors.

With the data in Table 4, you might either contact a laser diode provider or start an Internet search on your own. If you choose the direct search, you may take the first four keywords (RWS, single-frequency laser, 630–1120 nm/GaAs, CW, >80 mW) and you can quickly find a reasonable number of good contacts.

If you go to a laser diode vendor, these tables may save you a lot of time. The vendor will understand your needs immediately, and you can shortcut lengthy discussions on possible solutions that are not appropriate for your application.

Hui Zhou

Hui Zhou is a key account manager at FRAMOS (Berlin, Germany); he previously served as a sales engineer at Toptica eagleyard (also in Berlin) from 2017 to 2022.

Herwig Stange

Herwig Stange is a business development manager at Toptica eagleyard (Berlin, Germany).

Michael Kneier

Michael Kneier is VP of sales and marketing at TOPTICA EAGLEYARD (Berlin, Germany).