NIST engineers modulate continuous-wave laser to produce frequency comb

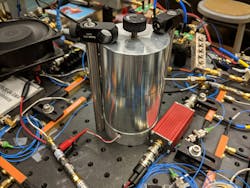

Physicists at the National Institute of Standards and Technology (NIST) and the University of Colorado (both in Boulder, CO) have used common electronics to create an electro-optically modulated continuous-wave laser that emits pulses at a rate 100 times higher than conventional ultrafast lasers at sub-optical-cycle accuracy, allowing it to generate precise optical frequency combs. The advance could extend the benefits of ultrafast science to new applications such as imaging of biological materials in real time. The NIST scientists developed a filtering method to reduce heat-induced electronic interference that otherwise would ruin the consistency of electronically synthesized light. The electronic signals are stabilized and filtered as they bounce back and forth inside a can-shaped aluminum cavity. Fixed waves then emerge at the strongest frequencies and block or filter out other frequencies.

Optical frequency combs are typically created with mode-locked ultrafast lasers. In contrast, NIST’s new electro-optic laser imposes microwave electronic vibrations on a continuous-wave laser operating at optical frequencies, effectively carving pulses into the light. The new electro-optic laser produces pulses every 100 ps rather than the usual 10 ns range. The laser produces optical pulses at a microwave rate, and each pulse is directed through a microchip waveguide structure to generate many more colors in the frequency comb. The laser was constructed using commercial telecommunications and microwave components, making the system very reliable. The combination of reliability and accuracy makes electro-optic combs attractive for long-term measurements of optical clock networks, or communications or sensor systems in which data needs to be acquired faster than is currently possible. The laser could also be useful for chemical and biological hyperspectral imaging. Reference: D. R. Carlson et al., Science (2018); doi:10.1126/science.aat6451.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.