Mechatronic assemblies and systems maker expands in biomedical

After completing a M.Sc. in Mechanical Engineering at Dortmund Technical University in 1986, Martin Hovestadt began his career as a production and planning engineer for Volkswagen in Germany. There, he gained invaluable experience with the manufacturing processes and organization of a large company. In 1991, his long-time friend Heinrich Jürgens invited him to become a managing partner of Jüke Systemtechnik, a company Jürgens set up the year before to manufacture mechatronic assemblies and systems for analytical applications.

The opportunity to help grow a company from scratch, to become an entrepreneur and potentially a company leader was too good to turn down. So, he took the plunge and the rest is history.Company development

Jüke started out manufacturing products for environmental analytics, but soon realized that for a small company, developing new products for a world market was very time-consuming and too risky. Instead, the company became a B2B service provider, producing mechatronic modules, complete devices, and complex systems for OEMs ranging from small startups to large end-user manufacturers such as GE, Olympus, Bruker, and Mettler Toledo. In 2007, Hovestadt was appointed as second CEO.

Since then, Jüke’s workforce has grown to 115 and now offers several services, including complete system development. Based on many years of practical experience as a system supplier, Jüke uses the latest technologies, CAD tools, and processes to design and develop optimal systems according to their customers’ specifications. The customer is involved in all stages of development, from initial detailed modelling and simulation of the systems, to prototyping, comprehensive testing, and documentation.

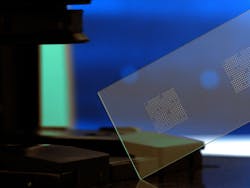

The production of complex mechatronic assemblies, complete devices, and systems is another of Jüke’s core competences. As an OEM provider, the company provides a holistic, in-house manufacturing service based on flexibility—manufacturing from prototype and one-off production to small- and medium-sized series, a highly qualified workforce, a modern infrastructure, and high productivity with CNC machining technology as well as precise laser welding and labeling.

Jüke operates a modern ERP system, specially developed test tools and testing devices, and high-performance logistics management. The company, together with partners, provides a comprehensive range of other services, including sheet metal processing, grinding technology, thermal treatment, and surface finishing.

Jüke also offers validation and regulation. These services cover the whole process, from the first draft through the entire development, prototyping and verification, and consulting for small companies new to the medical device market as well as global players with a long product history. The company has a team of professionals with application-specific knowledge in various areas of medical technology and in vitro diagnostics, and they can ensure medical devices comply with current legal requirements and that secure risk management is established. Finally, they provide advice on and establishment of a proactive and systematic process for post-market surveillance of medical devices.

Industry sectors

Approximately 60% of Jüke’s business is with European subsidiaries of customers headquartered in the U.S. and Japan, including Thermo Fisher, GE, Waters Corp., and Olympus; others include customers in Germany, many of which are medium-sized SMEs.Jüke operates in three industry sectors:

Medical technology. Development and manufacture of customized mechatronic assemblies and medical devices and systems—ranging from nuclear medicine to in vitro diagnostics. The company performs concept studies, mechanics construction, and electronics design, and offers firmware and software, development, creation of product documentation, production engineering, and assistance with the approval process.

Analysis, bio, and laboratory technology. Jüke handles the production of functional models, prototypes, and pilot series or complete series production for advanced biotechnology, laboratory equipment technology, and measurement technology. Products include sensors, measuring technology, signal processing, a liquid handling system, and gas analysis.

Optical technologies. The company also works with construction of assemblies and modules through to complete systems for optical assemblies, laser gauges, optomechanical assemblies, mechatronic systems, optoelectronic modules, electronic and mechanical assemblies, and ESD assembly workstations.Factors of success

Hovestadt attributes Jüke’s success to several factors like organic growth. Apart from raising capital for new buildings, the company has grown organically in small steps without external investment. This has enabled them to remain debt-free and to develop projects at a comfortable pace without time pressure from venture capitalists.

Jüke develops personal relationships to secure new business. Because their work is largely project-driven, the company places great importance on networking and attending leading trade shows such as SPIE Photonics West, SLAS: LASER World of PHOTONICS, MedtecLIVE, analytica, LAB.VISION, and Medica/Compamed.The future

Hovestadt’s vision for the next 10 years is to continue to focus on their three core industrial sectors; i.e., medical technology, biotechnology/laboratory analytics, while photonics radiopharmacy and nuclear medicine will continue to be important for Jüke, as will endoscopy. Demand for dental applications is also expected to grow. New projects are expected to emerge as a result of the growth of photonics. For example, Jüke is currently working on new projects involving the integration of IVDR photonics with microfluidics and optics for the analysis of a special component in the blood via the inner side of the lips.

For Hovestadt, it’s important that large companies are increasingly focusing on their core competencies and losing flexibility and speed in developments outside their core area. So when larger companies need flexibility and speed to market in establishing new technologies, they increasingly seek partnerships with smaller, flexible companies like Jüke. For this reason, small- and medium-sized enterprises, especially startups, will contribute even more to future innovation in Europe.

A new Medical Devices Regulation (MDR), which came into effect in Europe in May 2021, presented Jüke with unforeseen opportunities. It was intended to create a safer and sustainable international regulatory framework for manufacturers and healthcare professionals. Although in principle an admirable intention, many smaller manufacturers have been unable to keep existing devices on the market because of challenges such as a lack of notified body (NB) capacity, lack of EU guidance on certain aspects of the regulation, and lack of expert panels—and there’s a need for companies to carry out extensive testing to ensure materials used in existing medical devices comply with the stringent requirements of MDR.

Like all high-tech companies, Jüke’s personnel are one of its core assets. Although they have close relationships with local universities and research institutes, the company is having trouble recruiting and retaining skilled engineers due to the high demand for and shortage of STEM graduates.

Jüke may also encounter supply chain problems. The difficulty in sourcing components and long lead times, particularly from Asia, since Europe only produces 10% to 15% of the world market now, has created a number of significant problems. To tackle the problem, Jüke created a special task force to develop a sourcing strategy and minimize costs.In retrospect

In the early days, Hovestadt had small children and, on reflection, spent a lot of time working and not enough time with his family. “If I started again, I’d try to have a better work-life balance,” he says.

Hovestadt would also focus earlier on changing his business model. In the mid-1990s, Jüke had problems developing products. For example, in microtechnology, with partners who were not willing or able to share in the risk of development. This resulted in losing money and led Jüke to move from product manufacturing to become a B2B service provider. “If I started again, I would make the change to being a process-driven company earlier,” he says.

Sage advice

“First, you need to have a clear goal and a vision behind it,” says Hovestadt. “Second, niche markets are one thing, but if you want to industrialize in the field of medical technology, you will need to find a senior partner with the resources and know-how, particularly on regulation, to make your dream a reality. Using a venture capitalist and trying to do it on your own is not the best alternative. In my experience, startups are often afraid that a partner will take them over.”

But this is not always the case. Jüke, for example, works with several startups as a senior partner. “We take over the part of industrialization of the startup, not as a business angel or seed capitalist, to work as a collaborative partner providing advice on the market and regulation and oversee the industrialization of products,” he says.

Third, in developing B2B systems, Hovestadt stresses that internet marketing/social media is only one aspect. “The key to good marketing is to network via trade fairs and industry associations like EPIC so you can meet potential customers face-to-face and start collaborating on win/win projects,” he says. “As a small company, you may feel you don’t have the time, but in my view, there is no alternative to networking for effective marketing.”

Antonio Raspa | Ultrafast Solid-State Laser Product Manager, Luxinar

Antonio Raspa is ultrafast solid-state laser product manager at Luxinar (Kingston upon Hull, U.K.), and an editorial advisory board member at Laser Focus World. He has more than 35 years of experience with solid-state laser design, photonics components, and fiber optics.

He holds a MSc degree in Electrical Engineering from Politecnico di Milano with a specialization in Quantum Electronics. Before joining Luxinar, he served as senior photonics program manager at the European Photonics Industry Consortium (EPIC; May 2020 – September 2022), preceded by Quanta System (1988-2000) as R&D manager for the development of solid-state laser sources and custom photonics systems for industrial and scientific applications. During this period, he participated, as Ozone LiDAR specialist, to the Italian research program in Antarctica. He then worked at Trumpf (2000-2008) and Rofin-Sinar (2008-2009) as a Product Manager for industrial laser products and processes. In 2009 he returned to Quanta System, organizing and managing a new plant for the production of sterile optical fibers for surgery.