Each year, nearly 15% of the world’s food is lost and wasted before it even hits the retail market, according to the United Nations (UN) Environment Program and Food and Agriculture Organization. This is especially applicable to crops, says Evgeni Eltzov, a researcher of post-harvest and food sciences with Israel’s Agricultural Research Organization–Volcani Institute (Rishon LeZion, Israel), noting that half of all harvested food is lost due to rot caused by microorganisms.

Eltzov and fellow researchers, alongside a team from the Hebrew University of Jerusalem, are attempting to help alleviate problems like this—perhaps even cut them off at the pass—with a biosensor that can effectively detect and monitor the quality and health of crops earlier.

Based on bacterial detection, the researchers say their biosensor system will allow more efficient crop management during post-harvest, storage, and transport of crops. This will, in turn, reduce food losses.

While developing their biosensor, the team focused on potatoes, specifically the tubers—the swollen roots containing the plants’ starch and other nutrients that typically grow beneath the soil. Potatoes account for about 50% of Israel’s food exports; the country produces more than half a million tons of them every year, making this root vegetable and its health crucial to Israel’s economy.

The whole-cell bacterial biosensor monitors the luminescent responses of bacteria to changes in the volatile organic compounds (VOCs) that plants naturally emit in their surrounding environments. It can detect potato tuber soft rot disease caused by Pectobacterium, a pectinolytic enzyme widely distributed among fungi and bacteria in plants.

The biosensor also uses gas chromatography mass spectrometry, which can identify the differences between the volatile organic compound patterns of inoculated and non-inoculated potato tubers during early infection (see Fig. 1).

Every fruit and vegetable has hundreds of thousands of different chemicals that together construct specific patterns—essentially, patterns of their health. The concentration and composition of these chemicals usually stay constant, Eltzov explains, so this can act as a fingerprint of the constant and natural state of the plant according to the pattern of the concentration and composition of the chemical. If there is an abnormal situation such as pathogenic activity, the pattern changes, as do the concentration and composition. Infection alters the VOCs in healthy crops.

If a potato is infected with a pathogen, the fingerprint will change according to that specific pathogen. If you want to recognize and understand what is attacking the potato, just determine the pattern.

Such changes in crops typically happen at the early stages of growth. “When the plant comes up, it will look like a normal fruit or vegetable,” Eltzov says. “But it’s already changed its pattern before it reaches the surface because the pathogenic activity has already produced the different pathogens. So if you’re able to catch these changes earlier in the growth stage, which you can do with the biosensor, you’ll be able to detect something like rot at the dirt stage and treat it. You’ll be able to isolate it and not spread the infection around.”

In the team’s study, infection was detected with a bioreporter bacterial panel on the biosensor, made from genetically modified bacteria that measures biological toxicity. The researchers used the genetically modified bacteria to produce light in the presence of some chemicals surrounding the plant to analyze it. They could then measure it with optical sensors, which shone brighter in infected potatoes.

“The biosensor can detect rot continuously and in real time,” Eltzov says. “We can save a lot of food, thanks to this technology.”

What’s in the meat?

Biosensors have emerged as a viable tool in other food sectors, as well, including the meat industry. While the operation of this industry is typically very efficient, researchers at Concordia University (Montreal, QC, Canada) say unexpected issues, including lenient food inspection protocols and delays in exporting and transporting meat, prompt serious consequences—most notably spoilage. It could be handled earlier, avoiding illness, with a paper-based biosensor developed at Concordia.

“The challenge with current technologies to detect meat spoilage is that it is not portable and it’s not accessible to the consumer,” says Steve C. C. Shih, an associate professor of electrical and computer engineering at Concordia, whose lab is leading the research. He notes that only specialized laboratories have access to such equipment. “Detecting spoilage using traditional methods could also be lengthy. It does not provide results immediately.”

The team’s biosensor technology overcomes these issues.

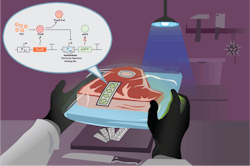

It features an optical genetic circuit that responds to the presence of putrescine, part of a class of molecules called biogenic amines (BAs) that indicate spoilage. BAs can be present at high levels in meats without any strange smells or colors emitted from the meat. Consuming high concentrations of BAs are typically associated with ailments including headaches, vomiting, and heart palpitations, and can increase risk of developing colorectal carcinoma.

Proteins that naturally bind to putrescine were used in the study, and the optical circuit placed onto paper that was observed under ultraviolet light. When there is putrescine present in the meat, the paper turns green, indicating the meat is spoiled (see Fig. 2). The biosensor relies on cell-free protein synthesis, according to Shih, which produces a protein that uses the biological system of a living cell, not the actual cell.In their study, the researchers tested the device with beef that was stored at three different temperatures—room, refrigerator, and freezer. The meat stored in the refrigerator and freezer showed very low levels of putrescine, indicating it was safe to eat, while the meat stored at room temperature showed high concentrations of putrescine—and all before any external signs of bacteria were present.

The team compared the results obtained with the biosensor to those acquired with chromatography, a conventional method used for food inspection, and they discovered the results from their biosensor were very close to those revealed via chromatography (see Fig. 3).“With this biosensor, we can significantly reduce health risks. We will know if the meat is spoiled before it smells,” Shih says.

The future

Scientists are working to combat food shortages and boost sustainability efforts worldwide now and well into the future.

The Hebrew University/Volcani Institute team has already applied their device beyond potatoes to other crops such as avocados and fruits. Using the biosensor, the team detected and studied larvae in mandarin oranges before they could be seen. Now, they’re working on a smaller biosensor that can better detect live activity in crops and be more effective.

“We need to be able to monitor the food throughout all of the phases—from the field to transporting them to the market,” Eltzov says.

Tools that can monitor continuously in real time, as Eltzov’s team’s biosensor does, provide the capability to maintain the monitoring and detection properly and quicker than with conventional techniques to prevent food decay and damage.

Shih says his team also intends to enhance their biosensor’s real-time monitoring system, by speeding up the time it takes to get results. Currently, the device requires a couple of hours to get an accurate result.

“The main alteration we would have to make is the actual sensing circuit,” Shih says. “This will need to be modified because our circuit is only specific for putrescine. We want to make a test that can give a better picture of spoilage, so we need to create a sensor that can detect all types of molecules that indicate spoilage, not just putrescine.”

Expanding the biosensor’s capabilities for applications beyond meat quality inspection is another goal.

“Our lab is currently working on a paper-based biosensor as a diagnostic tool for infectious diseases and viruses,” Shih says, adding environmental monitoring is another potential application.

Food loss and waste pose environmental issues, as the third largest source of greenhouse gas emissions in the world, according to the UN Environment Program. This makes such loss and waste a sizable contributor to an unstable climate and extreme weather events such as droughts and flooding.

The human population is growing every year, Eltzov notes, so the available land for agriculture is decreasing at that pace and environmental impacts increasing. Biosensors are positioned as a prime solution.

“Imagine how much food we could save with this biosensor,” Eltzov says, “and how we could help our environment.”

About the Author

Justine Murphy

Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.