Biomimetic sensor could speed disease detection

Researchers from the Massachusetts Institute of Technology (MIT; Boston, MA) Microsystems Laboratory, alongside a team from the Institute of Synthetic Bioarchitectures at the University of Natural Resources and Life Sciences (BOKU; Vienna, Austria), have developed a prototype sensor modeled after our bodies’ natural sensory systems to detect and identify the same molecules that naturally occurring cell receptors can (see video).

“We are inspired by the capability of natural cell surface membrane-anchored receptors that are embedded in the plasma membrane of cells to detect single-target signals among the noise versus signals, both for their sensitivity and their specificity,” says Shuguang Zhang, a principal research scientist in MIT’s Media Lab whose current research focuses on the design of biological molecules (see Fig. 1).

The team is designing a biomimetic system using just the ligand-binding part of the receptors, not living cells, as the sensing device. Cell membrane receptors undergo conformational changes after they bind to their specific ligands, Zhang explains. Such changes can be detected by exceedingly sensitive electrical means, especially with graphene-based electrical devices.

Triple-crown sensing

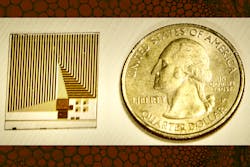

The new prototype device (see Fig. 2) combines three components: designer water-soluble receptor analogs, S-layer proteins, and graphene-based field effector transistors.

Modeling the water-soluble receptor analogs relies on the QTY code—a design method that transforms membrane proteins intrinsically insoluble in water into variants with water solubility, while also retaining composition and function. The MIT-led team’s design converts native water-insoluble cell membrane receptors (and other membrane proteins) into their water-soluble receptor analogs that retain their stability, structure, and biological functions.

Researcher Uwe Sleytr, an emeritus professor at the Institute of Synthetic Bioarchitectures, says the water-soluble receptor analogs have been bioengineered to have a Fc (fragment crystallizable) domain at its C-terminus (end of an amino acid chain) that can strongly bind to protein A/G, a recombined fusion protein that merges the immunoglobulin G antibody (IgG) domains of proteins A and G.

The S-layer protein—a class of bacterial surface protein that self-assembles onto surfaces to form a 2D crystal lattice—component of the sensing device gathers itself onto graphene and other electrically conductive surfaces that serve as the basis for electrical measurement.

Field-effect transistors designed for the prototype sensor are based in graphene, a single atomic layer of carbon 2D lattice that’s lightweight and extremely sensitive to electrical current flow and measurement.

“Our chip with a 2D lattice graphene coating has 256 individual sensing devices,” Sleytr says. “It can perform over 200 measurements of the ligand-binding individually to ensure accuracy and reproducibility, and the data is combined after the measurement.”

Combining components

S-layer proteins, akin to dense floor tiles or a chess board, can anchor and align the receptors with around 100% upward orientation for receptor binding site exposure to ligands in a 2D crystal lattice array on an electrical graphene surface. It also has an extremely high receptor density on the surface—over 1 trillion receptors per square centimeter (>1012 receptors/cm2).

“It’s similar to dense upward individual fine carpet fibers,” Sleytr says. “Or a dense grass lawn with individual grass blades pointing upward.”

With several hundred different receptors on cell membrane surfaces, the sensor’s receptors can be fused with the Fc of IgG, then anchored on the S-layer protein A/G. Each receptor, or combinations of receptors, like music CDs, can be exchanged to make various swappable chips. This changeable modularity is key for the new design, Sleytr says.

Pros and cons

Conventional biosensors follow what Zhang describes as a “bottom-up” approach. They identify analytes of interest and selectively detect them with probes such as antibodies or aptamers (short sequences of artificial DNA or RNA that bind a specific target molecule).

“These systems can be efficient to detect specific types of biomarkers but are intrinsically constrained by the availability and properties of probes. And they underperform in scalability and possibly alignment in the biomarker relevance in clinical settings,” Zhang says. “The natural receptors suffer from extremely poor water-solubility.”

The MIT/BOKU team takes a “top-down” approach. They’ve created a modular biomimetic architecture to overcome the bottleneck presented by traditional biosensing systems.

“Instead of searching for probes to detect target analytes, we identify critical receptors in human physiological processes, then redesign and integrate them with electronic devices to generate electrical outputs with biophysical significance,” Zhang says.

This “plug-and-play” architecture contains the membrane protein-S-layer dual-monolayer construct, Zhang adds, and the graphene-based field effect transistors are used for signal transduction.

“The construct is naturally multimodal, which overcomes one of the fundamental challenges to ultrasensitive bioelectronic detections in obtaining well-defined sensing structures on device surfaces,” Zhang says. “The ‘top-down’ design approach and modularity of the overall architecture endows the system with unprecedented scalability. And it has the potential to fabricate a true multipurpose electrochemical communication system that behaves exactly like a biological entity, but with electrical outputs and controls.”

What’s next?

The researchers say their sensing device should be easy to use at home. The readout could be sent to a smartphone, much like wearable devices that measure things like heart rate and daily movement.

“Ideally, people can use it daily, weekly, or monthly to measure various health-related molecules noninvasively—from urine, saliva, sweat, and tears, for example,” says Rui Qing, a former MIT research scientist who worked on the new sensor. “Many molecular events take place months or years ahead of physical symptoms. Most people have annual physical exams, but something can go wrong in between. The sooner an individual catches abnormal molecular signals, the sooner they can visit a medical professional for a specific and thorough checkup.”

“We hope the system can gradually enable easy point-of-care testing and precision medicine,” Qing adds, in healthcare settings or at home to screen for diseases such as cancer or metastatic tumors that are difficult to diagnose.

About the Author

Justine Murphy

Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.